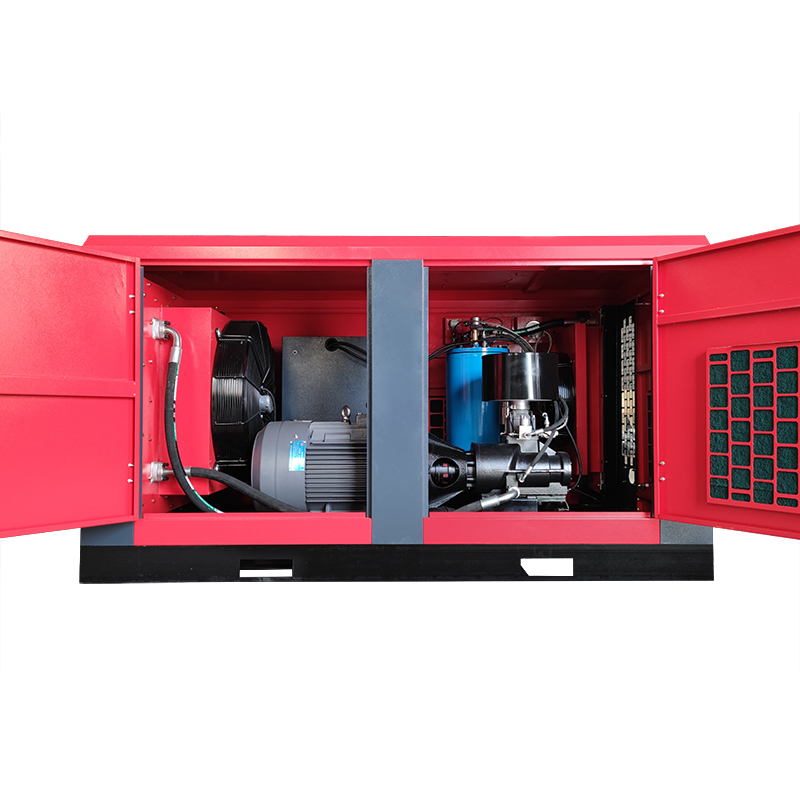

Elevate your industrial operations with our Stationary Electric Air Compressor, a symbol of reliability and efficiency. This electric compressor offers sustainability by eliminating the need for fuel, delivering a consistent supply of compressed air for heavy-duty applications. Built to withstand harsh industrial environments, it ensures uninterrupted performance, keeping your operations running smoothly. Trusted globally for its quality and service excellence, this compressor is the ultimate choice for upgrading your industrial setup and ensuring continuous productivity.

SOLLANT Energy-Saving Two-Stage Mobile Compressor, as the leader of energy-saving mobile screw air compressors in Turkey, is committed to providing customers with more economical, efficient and energy-saving mobile air compressors.

We provide high-level products and services for global oil and gas extraction, pipeline construction, mine drilling and blasting, water well drilling, sand mining and dredging, infrastructure construction and other fields. Sollant mobile machine adopts energy-saving two-stage spindle with high compression efficiency, a powerful brand motor, an efficient cooling system, stable and reliable control system, and its performance is even better!

Smarter and more human

More efficient and energy-saving

More stable and reliable

More environmentally friendly and more convenient

Energy-efficient product design concept

Carefully designed for customers to achieve better energy-saving results, saving up to 30% of fuel!

Carefully designed for customers to achieve better energy-saving results, saving up to 30% of fuel!

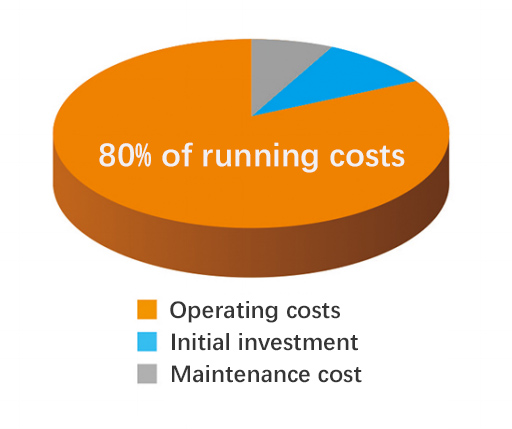

Application strategy for compressor products: Reduce operating costs!!!

During the entire life cycle of a diesel mobile screw compressor, operating costs account for up to 80% of the total cost. Reducing the fuel cost during the operation of a diesel mobile screw compressor plays a decisive role in reducing the overall cost of the machine’s life cycle. Therefore, reducing product operating costs has become an increasingly important focus for users.

Energy-saving drive all-in-one machine

Ultra-wide voltage start, simple wiring, compact design, supports remote control, and comprehensive protection functions

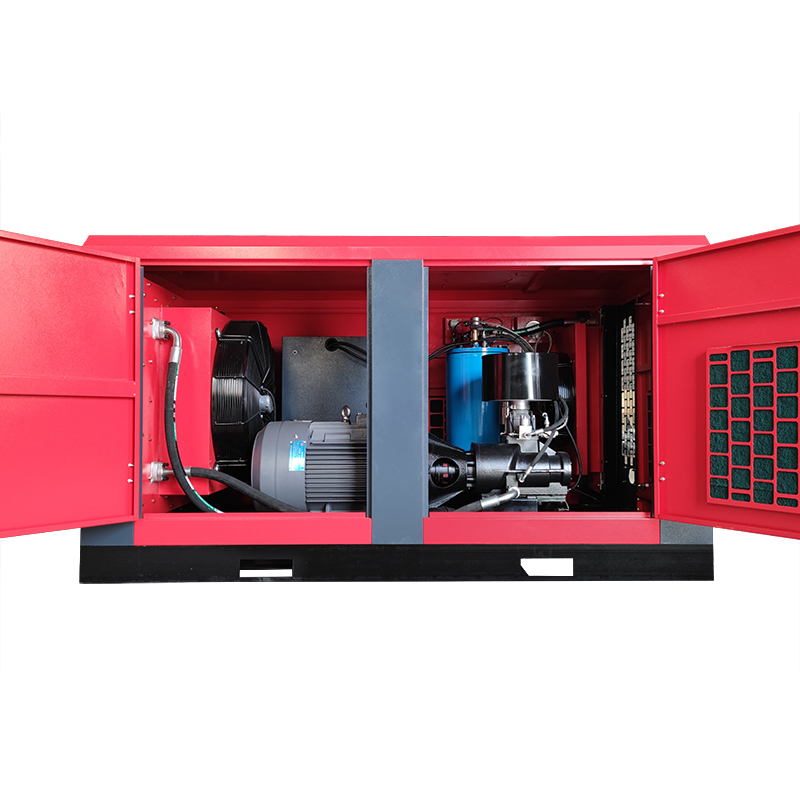

Two-stage screw air end

■Large rotor, low speed

■ Low-pressure ratio, high efficiency

■Energy saving and reliable

Super efficient motor

Super IE3 high-efficiency motor, low speed and high torque

Intake valve

Integrating anti-return, proportional adjustment and other functions into one, no wearing parts, more energy-saving and reliable

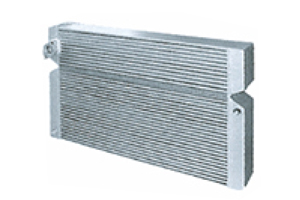

Heat sink

It adopts a side-entry structure, which makes installation and maintenance more convenient. The aluminum plate-fin type increases the heat exchange area with the air, effectively improving the cooling effect.

Air filter

Equipped with a safety filter element to more effectively protect the air end and engine in dusty environments

Microcomputer controller

Simple and convenient push-button, durable intelligent control, all-round performance parameter warning monitoring display, supports remote joint control of computer platform

Flexible coupling

High elasticity, strong ability to absorb shock and vibration. Compact structure, easy installation, maintenance-free. During axial transmission, it has good radial and angular compensation capabilities.

Oil and gas barrel

Adopt optimal flow rate and structural design, small oil content, easy maintenance

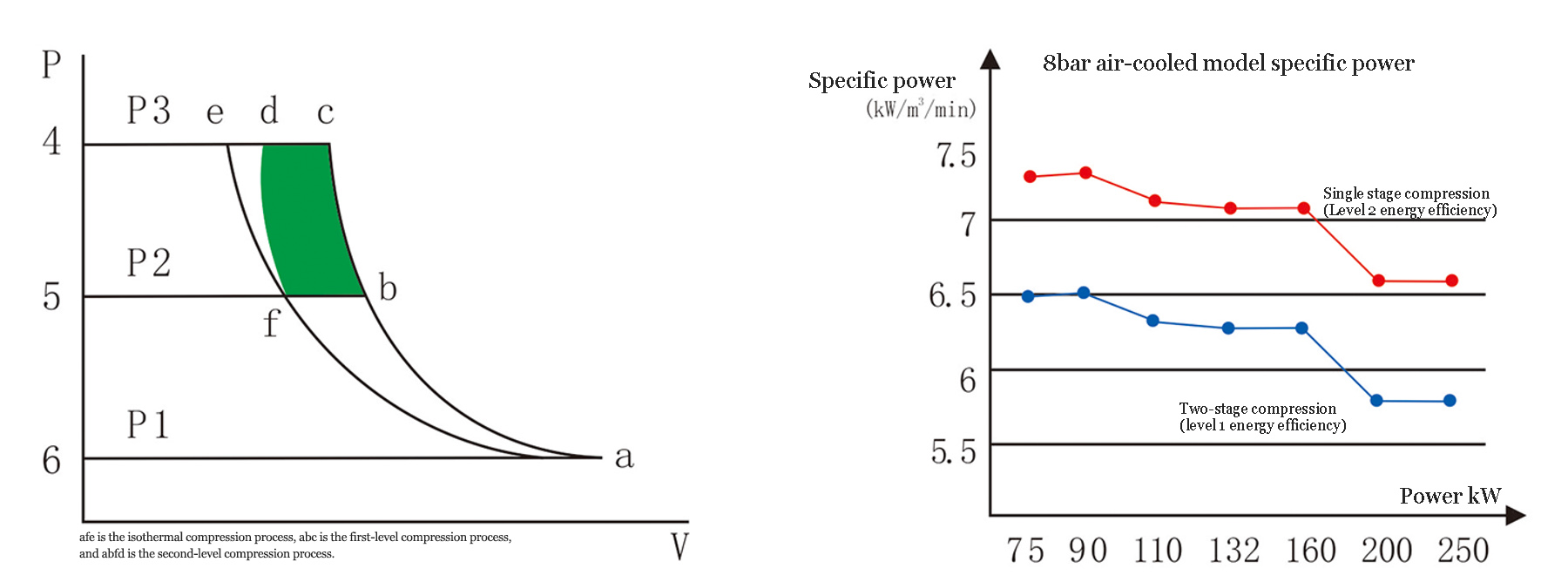

◆The operating temperature is lower than that of single-stage compression, and it tends to be more power-saving isothermal compression, with a theoretical energy saving of 8%.

◆The compression ratio of each stage is lower, the internal leakage is reduced, and the volumetric efficiency is increased by 5~10%.

◆It is helpful to adjust the rotor of each stage to achieve the optimal linear speed range of 25~35m/s, and obtain the highest compression transmission efficiency.