We hope to let you know our advantages and win-win cooperation in the least time.

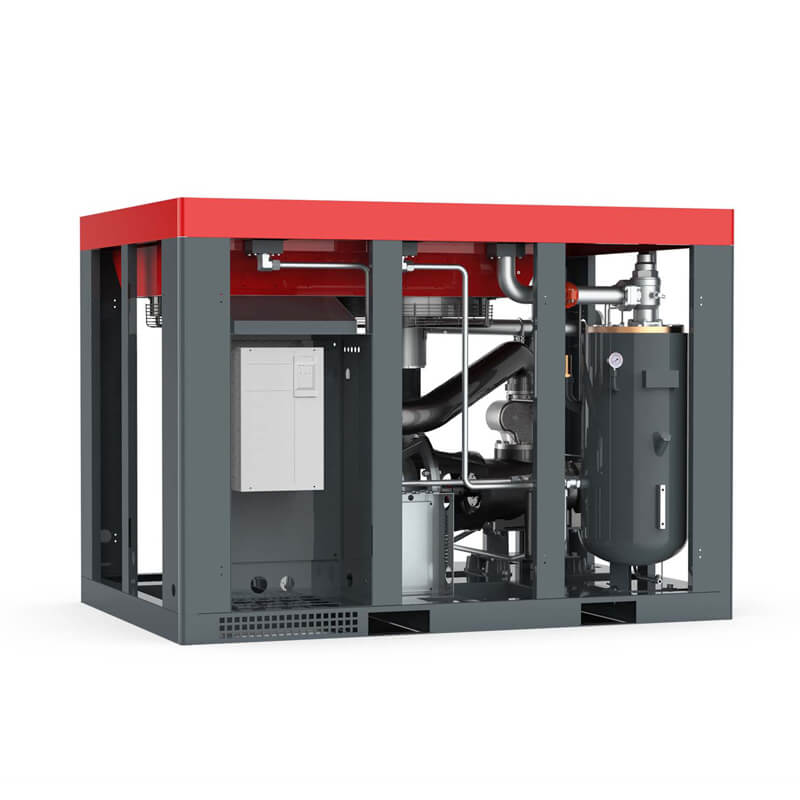

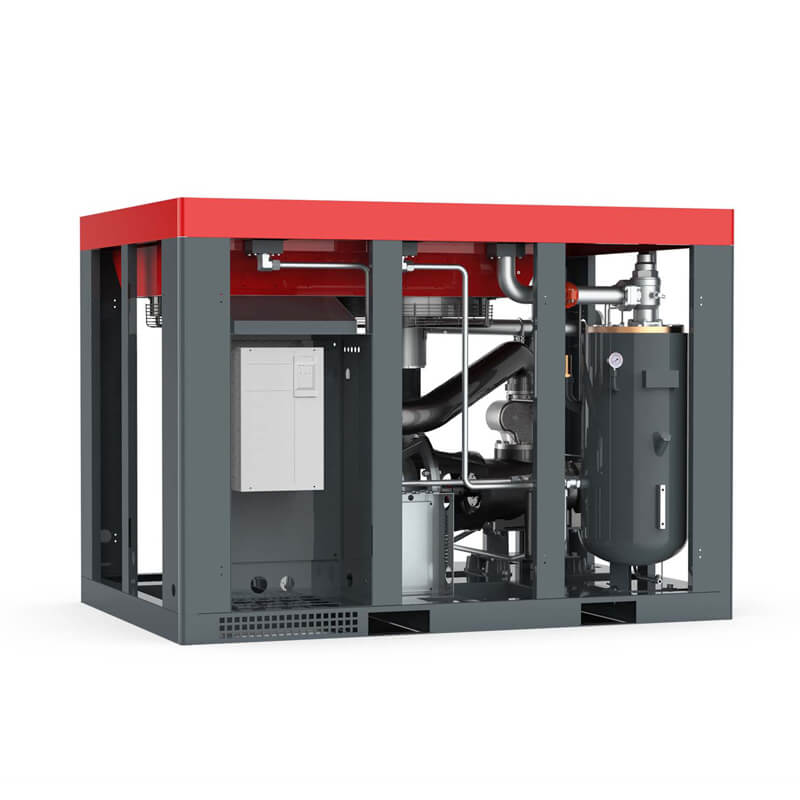

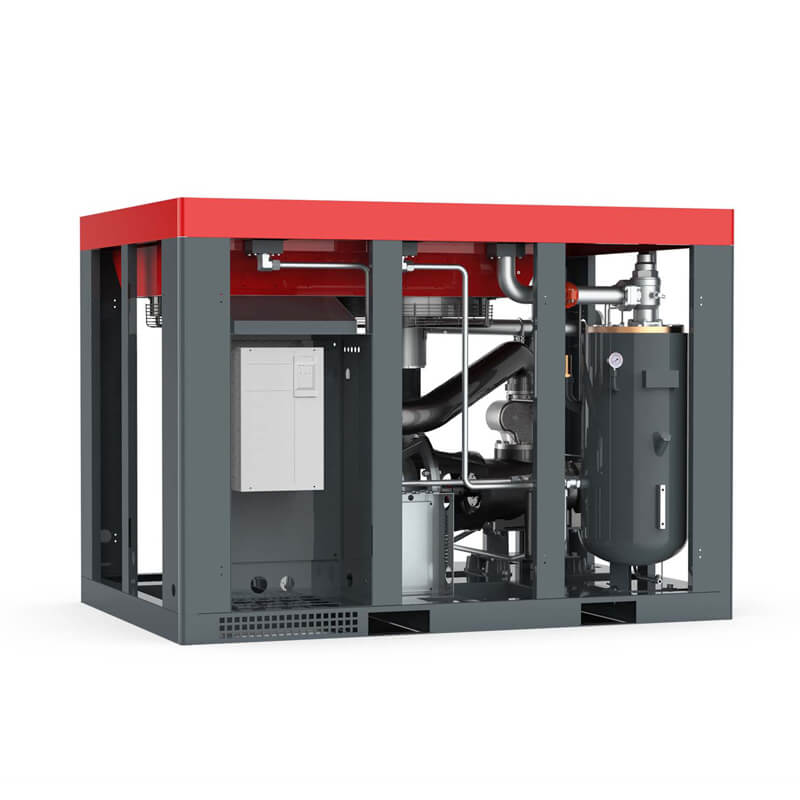

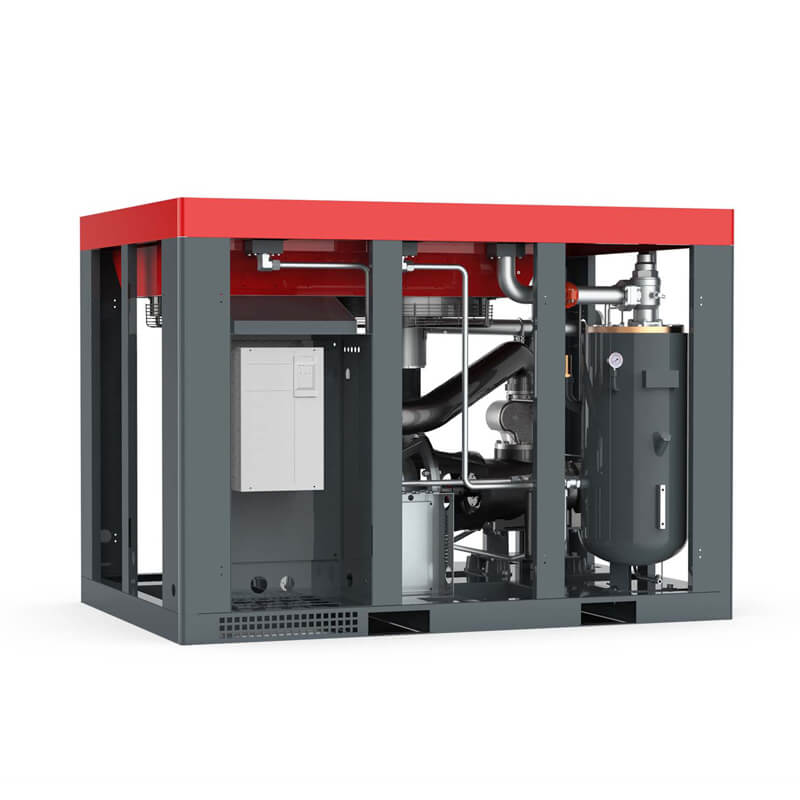

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In the heart of modern industries, the rhythmic hiss of air compressors echoes, orchestrating the harmonious dance of machinery and processes. These silent workhorses form the backbone of numerous sectors, from manufacturing to energy production, where their ability to generate compressed air transforms complex operations into seamless symphonies of productivity.

As industries continue to evolve, the choice of air compressor becomes paramount—a decision that can spell the difference between efficiency and inefficiency, productivity and stagnation.

Air compressors, often operating unnoticed in the background, are the unsung heroes that power pneumatic tools, control systems, and a myriad of processes essential for modern production.

They serve as the very lungs of factories, breathing life into diverse applications such as automotive assembly, packaging lines, and construction machinery. Their role isn’t just limited to providing pressurized air; they are catalysts that propel production forward, facilitating precision and speed across a spectrum of industries.

Within the realm of air compressors, two stalwart contenders emerge: twin-screw and single-screw air compressors. As the machinery of industries grows more sophisticated, the choice between these two becomes increasingly significant.

This article delves deep into their intricacies, offering an insightful comparison that navigates their advantages, limitations, and suitability for diverse applications. By shedding light on their operational differences, we seek to empower industries with the knowledge needed to make informed decisions.

Selecting the appropriate air compressor is akin to choosing a brush for an artist or a tool for a craftsman—it’s the essence of precision. With each industry having its unique demands, the right choice hinges on understanding the nuances of twin-screw and single-screw compressors.

The consequences of an ill-fitted choice can ripple across operations, impacting efficiency, energy consumption, and overall productivity. Therefore, this comparison isn’t just a quest for information; it’s a guide to making the right choice, tailored to the specific needs of each industry and application.

To comprehend the essence of twin-screw and single-screw air compressors, one must delve into the intricacies of their operational mechanisms. Twin-screw compressors orchestrate a synchronized dance of two interlocking rotors, drawing air in, compressing it through their meshing lobes, and expelling it with precision. This mechanism guarantees continuous airflow, lending itself to applications demanding constant pressure.

In contrast, single-screw compressors harness the power of a single helical rotor that rotates eccentrically within a stator. Air is drawn in and compressed along the rotor’s spiral path, leading to intermittent compression cycles. The simplicity of this mechanism offers advantages in certain scenarios where steadiness might be less crucial.

Beyond their fundamental mechanisms, twin-screw and single-screw compressors differ in their construction. Twin-screw compressors boast dual rotors, often meshed in a helical configuration, ensuring minimal leakage and superior efficiency. This design caters to industries requiring continuous and stable airflow, promoting higher output capacities and efficiency.

On the other hand, single-screw compressors exhibit a simpler construction, with a solitary helical rotor placed eccentrically within a cylindrical housing. This design lends itself to applications where fluctuations in air demand can be accommodated without sacrificing performance. While intermittent compression might not suit every scenario, it finds a foothold in industries that value simplicity and durability.

Understanding these core differences forms the foundation for selecting the most fitting air compressor for various industrial applications. From the precision of twin-screw compressors’ continuous operation to the reliability of single-screw compressors’ uncomplicated design, each type offers distinct advantages that cater to specific operational needs.

Efficiency and Output Capacity

Efficiency stands as a defining attribute in the realm of air compressors, directly impacting energy consumption and operational costs. Twin-screw compressors shine in this aspect, exhibiting higher efficiency due to their continuous operation. This seamless flow minimizes energy loss and optimizes output, making them ideal for applications that demand a steady supply of compressed air. Single-screw compressors, while efficient, might exhibit slightly lower efficiency due to their intermittent compression cycles.

Output capacity plays a pivotal role in industries with fluctuating air demands. Twin-screw compressors maintain their efficiency even under varying loads, ensuring consistent pressure and flow. This adaptability suits industries with continuous production processes. Conversely, single-screw compressors might require more fine-tuning to cater to varying demands efficiently, potentially making them better suited for applications with intermittent usage.

Compression Process and Mechanisms

Twin-screw compressors execute compression through intermeshing rotors that draw air in, compress it in the interlobe spaces, and expel it. This continuous process generates minimal pulsation, ensuring smoother airflow. The continuous compression mechanism is advantageous in maintaining stable pressure for precision tasks.

Single-screw compressors employ a single rotor to draw in and compress air along its helical path within the stator. The resulting intermittent compression can lead to slightly higher pulsation in airflow. While they might require more substantial effort to balance pressure fluctuations, their design remains robust and dependable, especially in scenarios where constant pressure isn’t a critical requirement.

Understanding the unique dynamics of the compression process for each type is vital for industries seeking the right match for their operational needs. Twin-screw compressors excel in applications demanding constant pressure and flow, while single-screw compressors showcase their value in scenarios where simplicity, durability, and adaptability are prized attributes.

Twin-Screw Air Compressors

Twin-screw air compressors come with a suite of advantages that make them a favored choice in specific industrial contexts. Their continuous operation mechanism ensures a consistent airflow and pressure output, making them optimal for applications requiring precision. These compressors also exhibit higher efficiency due to reduced energy losses during the compression process. The streamlined airflow generated by their intermeshing rotors leads to smoother operation and reduced pulsation, essential for tasks demanding accuracy.

However, twin-screw air compressors aren’t without their limitations. The initial investment cost for these compressors tends to be higher compared to their single-screw counterparts. This upfront expense might deter industries with budget constraints from opting for twin-screw compressors. Additionally, these compressors might have slightly higher maintenance requirements due to their intricate design. Despite these considerations, their efficiency and reliability often outweigh these limitations, especially in industries where continuous operation is vital.

Single-Screw Air Compressors

Single-screw air compressors offer their own set of advantages that cater to specific operational needs. Their simplicity in design translates to lower maintenance requirements, reducing downtime and associated costs. This straightforward mechanism also contributes to their durability, making them a resilient choice for industries with demanding conditions. The intermittent compression process can be advantageous in applications where constant pressure is not the primary concern.

Nevertheless, single-screw air compressors also have their limitations. In certain scenarios, their intermittent compression process might result in slightly higher pulsation, affecting the uniformity of compressed air supply. While they remain efficient, especially for applications with fluctuating demands, they might not match the continuous operation efficiency of twin-screw compressors. It’s important to evaluate these limitations in the context of specific operational requirements.

Understanding the distinct advantages and limitations of both twin-screw and single-screw air compressors empowers industries to make informed decisions based on their operational priorities and constraints. Whether it’s the continuous operation of twin-screw compressors or the simplicity of single-screw compressors, each type offers a unique blend of attributes that align with different industry needs.

Industries and Applications for Twin-Screw Compressors

Twin-screw compressors find a stronghold in industries that prioritize continuous and precision-oriented processes. These include manufacturing sectors such as automotive, electronics, pharmaceuticals, and food processing. Additionally, they are extensively used in petrochemicals, where a consistent supply of compressed air is crucial for maintaining production efficiency.

The characteristics of twin-screw compressors align seamlessly with the needs of these industries. Their continuous operation ensures a steady flow of compressed air, essential for maintaining consistent quality and precision during manufacturing processes. Their high efficiency and smoother operation also make them ideal for industries aiming to optimize energy consumption and reduce production costs.

Industries and Applications for Single-Screw Compressors

Single-screw compressors carve a niche in industries where simplicity, durability, and adaptability are paramount. Sectors such as agriculture, construction, and small-scale manufacturing often favor these compressors. They also find a place in remote or harsh environments where straightforward and reliable equipment is essential.

Single-screw compressors are particularly well-suited for applications that don’t demand constant pressure and can accommodate intermittent airflow. Their rugged design and reduced maintenance needs cater to industries where extensive maintenance downtime is undesirable. These compressors are a preferred choice in scenarios where initial investment costs and operational simplicity are prioritized over continuous and precision-based processes.

Understanding the specific needs and priorities of different industries allows for the selection of the most suitable air compressor type. Twin-screw compressors shine in sectors that demand precision and continuous operation, while single-screw compressors thrive in environments valuing reliability, simplicity, and adaptability. The right choice ensures optimal performance and productivity for diverse industrial applications.

Initial Investment and Operating Costs

When considering air compressors, the initial investment plays a crucial role. Twin-screw compressors tend to have higher upfront costs due to their intricate design and efficiency-enhancing features. Single-screw compressors, on the other hand, are generally more straightforward and cost-effective in terms of initial investment.

Long-Term Operating Costs and Energy Savings

While twin-screw compressors might have a higher initial price tag, they often demonstrate higher energy efficiency, leading to reduced operating costs in the long run. Their continuous operation and streamlined airflow contribute to energy savings over time. Single-screw compressors, while efficient, might have slightly higher energy consumption and maintenance costs, making it important to consider the full lifecycle cost.

Maintenance Requirements

Maintenance is a critical consideration for any industrial equipment. Twin-screw compressors’ design complexity might lead to slightly higher maintenance requirements, including rotor maintenance and system checks. Single-screw compressors, with their simpler design, generally have lower maintenance demands.

Regular maintenance is essential for both types to ensure efficiency and longevity. While twin-screw compressors might require more attention, their continuous operation justifies the effort. In contrast, the simplicity of single-screw compressors reduces maintenance efforts but might necessitate slightly more frequent checks due to the intermittent compression process. Balancing maintenance requirements with potential downtime and associated costs is pivotal in decision-making.

Available Space and Installation

Physical space availability is a practical consideration in compressor selection. Twin-screw compressors typically require more space due to their larger size and additional components. Single-screw compressors, being relatively compact, might be preferable when space is limited.

Installation ease is another factor to evaluate. Single-screw compressors often have a simpler installation process due to their compact size and straightforward design. Retrofitting existing systems might also be easier with single-screw compressors. Twin-screw compressors, while more complex to install, might offer enhanced performance benefits that justify the installation effort.

Taking into account these factors—initial investment, operating costs, maintenance requirements, available space, and installation considerations—allows industries to make a well-informed decision. Whether it’s the efficiency of twin-screw compressors or the simplicity of single-screw compressors, understanding these aspects ensures the chosen air compressor aligns with operational needs and financial constraints.

In the dynamic landscape of industrial machinery, air compressors stand as essential tools that power a wide array of operations across various sectors. Among the prominent players in this field, Sollant emerges as a key manufacturer specializing in twin-screw air compressors.

Headquartered in Turkey, Sollant has solidified its reputation as a reliable and innovative producer of cutting-edge air compression solutions. With a global presence, a legacy of production expertise, and a dedicated research and development team, Sollant continues to shape the industry through its commitment to excellence.

With a far-reaching network of offices and outlets spanning across the globe, Sollant’s influence extends well beyond its Turkish origins. Its strategic locations enable the company to efficiently serve its diverse customer base, ensuring that industries worldwide have access to high-quality twin-screw air compressors tailored to their specific needs. Sollant’s international presence underscores its commitment to providing unparalleled solutions that cater to the demands of a global market.

Sollant’s journey in the realm of twin-screw air compressors has been enriched by its extensive experience in the field. With years of refining its manufacturing processes, the company has honed its capabilities to deliver top-notch products that consistently meet and exceed industry standards. Complementing its production proficiency is a dedicated research and development team that continuously pushes the boundaries of compressor technology. This team’s innovative approach ensures that Sollant remains at the forefront of advancements, consistently introducing new features and enhancements to its product lineup.

Sollant’s commitment to quality is evident in its adherence to multiple international standards governing air compressor production. The company’s products are not only designed to meet stringent performance benchmarks but also to ensure safety, reliability, and environmental responsibility. This adherence to international standards reinforces Sollant’s dedication to providing customers with products that excel not only in efficiency but also in meeting global quality expectations.

At the heart of Sollant’s offerings is its specialization in twin-screw air compressors. These compressors are recognized for their efficiency, reliability, and versatility in meeting a spectrum of industrial demands. Sollant’s twin-screw air compressors are engineered to deliver consistent and efficient performance, making them a valuable asset across industries ranging from manufacturing and construction to automotive and beyond.

Sollant’s position as a leading manufacturer of twin-screw air compressors is a testament to its unwavering dedication to innovation, quality, and global reach. With its roots in Turkey and a global presence, the company is poised to shape the future of air compression technology. Backed by years of production expertise, a visionary research and development team, and a commitment to international standards, Sollant continues to redefine the standards of excellence in the field of twin-screw air compressors.

In conclusion, the comparison between twin-screw and single-screw air compressors reveals a range of factors that guide their selection for industrial applications. Both compressor types offer unique advantages and considerations that address various operational needs.

The importance of selecting the appropriate compressor type cannot be overstated. Factors such as efficiency, output capacity, maintenance requirements, and adaptability directly impact operational success. Industries must carefully evaluate their specific requirements to make a well-informed choice that aligns with their production demands and goals.

Choosing the right air compressor—be it a twin-screw or single-screw variant—has a profound impact on operational efficiency and cost-effectiveness. Twin-screw compressors excel in continuous operation and energy efficiency, making them ideal for high-demand environments. Single-screw compressors offer simplicity and reliability, particularly suitable for applications with varying air demand.

By selecting the right compressor type, industries can achieve enhanced productivity, reduced energy consumption, and optimized maintenance costs. The decision is not just about choosing between two technologies but about aligning industrial processes with the most suitable solution. The careful evaluation of these factors sets the stage for improved efficiency, sustainability, and success in a competitive industrial landscape.