We hope to let you know our advantages and win-win cooperation in the least time.

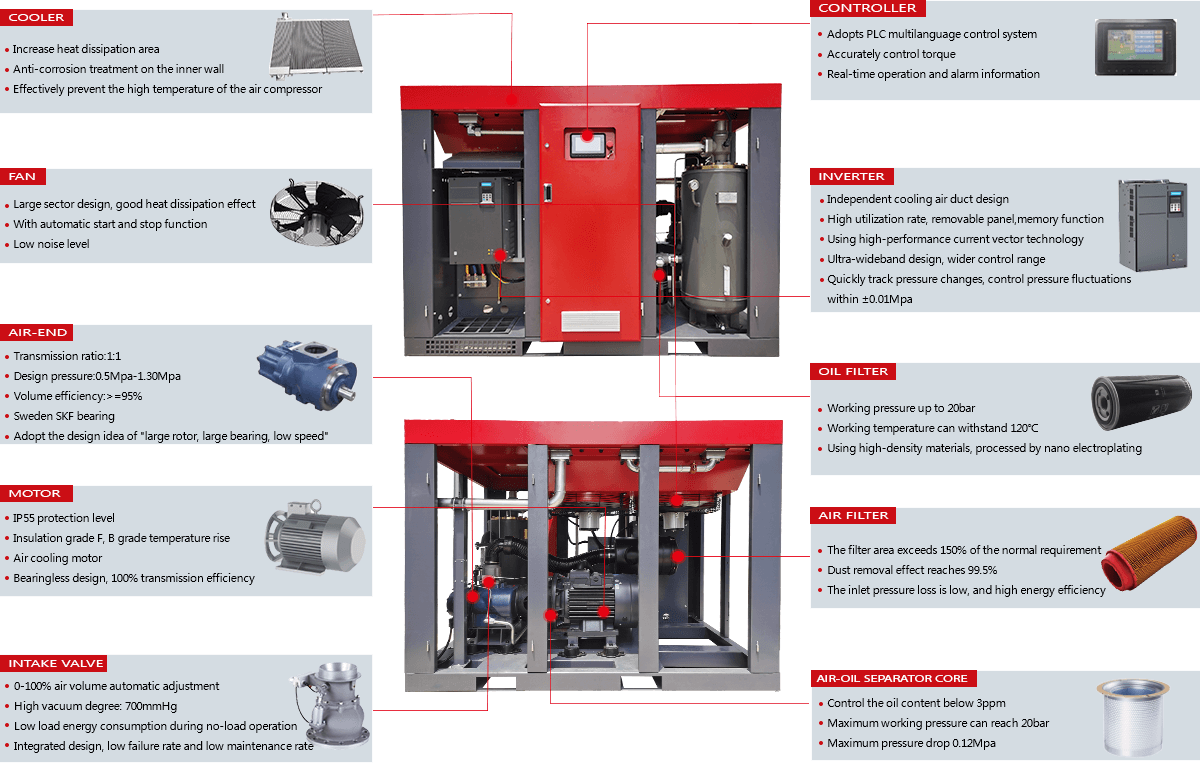

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In the dynamic landscape of industrial production, the hum of machinery, the precision of assembly lines, and the power of tools converge to shape the modern world. Amidst this symphony of activity, a silent yet pivotal player emerges: the air compressor.

As an unsung hero of manufacturing, air compressors breathe life into countless processes, making the impossible attainable and the intricate achievable. Within this realm, the importance of versatility becomes a guiding star, illuminating the path to meeting the diverse and ever-evolving demands of industrial production.

The industrial realm is a tapestry woven with threads of innovation, ranging from automotive assembly to food processing and everything in between. Each sector, with its unique requirements and challenges, demands solutions that can adapt, evolve, and excel. This is where the spotlight falls on versatility—an attribute that underpins the backbone of manufacturing efficiency. It is with this understanding that we embark on a journey to explore how screw air compressors, as champions of adaptability, seamlessly accommodate the wide spectrum of needs across industries.

The realm of industrial production is a vibrant tapestry woven with threads of innovation and precision. Within this intricate fabric, a diverse array of sectors converges, each bearing its own set of demands and challenges.

At the heart of this convergence lies a common denominator: the reliance on compressed air. From heavy machinery to delicate assembly lines, compressed air serves as the lifeblood, propelling processes forward and powering industries to greatness.

Compressed air, often dubbed the “fourth utility,” occupies a pivotal role in a multitude of sectors. Manufacturing, construction, automotive, electronics, food and beverage, pharmaceuticals, and textiles are just a glimpse of the expansive tapestry that depends on the seamless flow of compressed air.

In manufacturing, compressed air drives pneumatic tools, ensures accurate alignment of components, and propels conveyor belts with precision. The construction sector relies on it for powering jackhammers, drills, and machinery, while the automotive industry employs it to ensure efficient assembly and paint application. The realm of food and beverage demands clean and contaminant-free compressed air for packaging and bottling, while electronics manufacturing relies on its precision for delicate soldering and assembly processes.

The varied sectors within industrial production underscore the need for solutions that can seamlessly adapt to different requirements. The machinery that propels an assembly line may drastically differ from the precision tools employed in electronics manufacturing. From high-pressure applications demanding force to low-pressure processes requiring finesse, the demand for adaptability is ever-present. This intricate dance of requirements necessitates a unifying force—an adaptable solution that can cater to the divergent needs of these sectors.

In this dynamic landscape, the versatility of screw air compressors comes to the forefront, offering a solution that aligns seamlessly with the diverse demands of industrial production. As we navigate the industrial tapestry, the versatility of these compressors emerges as a beacon, illuminating the path toward enhanced efficiency, reliability, and innovation across sectors.

Screw air compressors, the unsung chameleons of industrial production, derive their versatility from their ingenious working principle. At their core, these compressors utilize a pair of interlocking helical screws to compress air. This mechanism not only ensures efficient compression but also lays the foundation for their remarkable adaptability—a trait that propels them to the forefront of various industries.

The hallmark of screw air compressors lies in their inherent adaptability. These compressors possess a unique ability to adjust to varying pressure and flow requirements, making them the Swiss Army knives of compressed air solutions.

Whether it’s high-pressure tasks demanding forceful air delivery or low-pressure operations requiring precision, screw air compressors possess the dexterity to conform. This adaptability isn’t just a mechanical feature; it’s an embodiment of their versatility to seamlessly integrate into different industrial processes.

The canvas on which screw air compressors paint their versatility spans far and wide across the landscape of industrial production. In manufacturing, they breathe life into pneumatic tools, driving precision riveting in one instance and powering large-scale metal fabrication in another.

The construction sector harnesses their power to propel jackhammers with force or run delicate power tools with finesse. Automotive production lines find them indispensable for maintaining consistent air pressure in pneumatic systems, while the pharmaceutical industry relies on them for critical operations like capsule filling and sealing. Even the realm of textiles witnesses their prowess in powering looms and machinery.

From food packaging to electronics manufacturing, screw air compressors traverse the industrial spectrum with grace, adapting their functionality to suit the specific needs of each sector. Their versatility acts as a unifying force, knitting together the diverse demands of different industries into a cohesive symphony of efficiency.

As we explore the far-reaching applications of screw air compressors, their adaptability emerges as a key factor that sets them apart. Their chameleon-like ability to seamlessly blend into various industrial processes underscores their importance as solutions that address the multifaceted requirements of modern manufacturing.

Amid the dynamic landscape of industrial production, the quest for efficiency isn’t a one-size-fits-all endeavor. This is where the art of customization steps in, and screw air compressors excel as virtuosos in creating tailored solutions that harmonize with the unique needs of diverse industries.

Precision Tailoring for Optimal Performance

Screw air compressors, with their inherent adaptability, serve as a canvas for customization. The power to tailor their performance—whether in terms of pressure, flow rate, or functionality—enables them to seamlessly integrate into various production processes. This precision tailoring ensures that industries can optimize their compressed air systems to match the demands of their specific applications. It’s the difference between a symphony resonating perfectly in tune and a discordant note disrupting the harmony.

Elevating Efficiency through Personalization

In the pursuit of operational excellence, tailored solutions reign supreme. Customized screw air compressors emerge as catalysts in optimizing production efficiency. By aligning compressor performance with precise requirements, industries can avoid energy wastage, reduce downtime, and enhance overall productivity. This personalized touch serves as a cornerstone in the larger goal of streamlining operations and maximizing output.

Industries Transformed through Customization

The transformative impact of customized screw air compressors reverberates across industries. In the automotive sector, where precision assembly is paramount, tailored compressors ensure consistent air pressure for paint booths and pneumatic systems. Food packaging operations benefit from specialized compressors that provide contaminant-free air to meet stringent hygiene standards. Even in pharmaceutical manufacturing, where adherence to specific regulations is critical, customized solutions ensure compliance while maintaining optimal production conditions.

The textile industry witnesses the magic of customization, where tailored compressors power looms and equipment with precision, enabling seamless fabric production. From electronics to aerospace, the ability to calibrate screw air compressors to the exact specifications of each application marks the zenith of efficiency and effectiveness.

As we navigate the industrial landscape, the role of customized screw air compressors stands as a testament to the marriage of innovation and adaptability. They pave the way for industries to reach their zenith of efficiency by offering solutions that are as unique as the challenges they aim to overcome.

In the intricate dance of industrial production, the pursuit of efficiency takes center stage. As industries seek ways to optimize their processes, the versatility of screw air compressors emerges as a guiding light—a beacon that leads to enhanced efficiency and substantial energy savings.

The adaptable nature of screw air compressors allows them to walk the delicate tightrope between supplying sufficient compressed air while avoiding energy wastage. When demand fluctuates—whether due to varying workloads or different stages of production—these compressors gracefully modulate their output.

By matching air supply with the precise requirements, they prevent the excess energy consumption often associated with fixed-capacity systems. This ability to maintain a harmonious equilibrium between output and demand marks a pivotal step towards energy efficiency.

The quantifiable impact of screw air compressors’ adaptability is best illustrated through data and case studies. In a manufacturing environment, a case study might showcase how a customized screw air compressor dynamically adjusts its output during peak and off-peak hours, resulting in significant energy savings over time. A pharmaceutical plant could reveal how the compressor’s adaptability reduced energy consumption by 20%, aligning with varying production phases.

Such narratives of success reinforce the assertion that screw air compressors, through their versatility, actively contribute to energy savings and operational efficiency. By minimizing energy wastage and optimizing compressed air distribution, these compressors stand as champions of sustainability and profitability alike.

In the intricate choreography of industrial production, reliability emerges as a non-negotiable cornerstone. Amidst the whirlwind of operations, the reliability and steadfast performance of screw air compressors stand as pillars, upholding the seamless rhythm of diverse industries.

Screw air compressors have earned their reputation as stalwart companions through their unwavering consistency. Driven by their robust engineering, these compressors deliver a dependable stream of compressed air, a lifeline that fuels everything from pneumatic tools to complex assembly lines. This reliability is a testament to their design, which eliminates the fluctuations often associated with other compressor types. Whether in automotive manufacturing or textile production, screw air compressors perform as unwavering backbones, ensuring that the beat of production remains constant.

While the pace of industrial production may be relentless, the operating conditions can be equally demanding. The durability of screw air compressors shines in the face of adversity, as they navigate varying environments, from pristine clean rooms to rugged construction sites. Their rugged construction, fortified with quality materials, equips them to withstand the challenges of diverse industries. This durability translates into minimized downtime, a critical factor in ensuring optimal production efficiency. Unplanned downtime due to compressor malfunctions becomes a rarity, as these compressors stand resilient in the face of rigorous operating conditions.

The reliability of screw air compressors isn’t confined to consistent operation—it extends to the broader realm of operational efficiency. Reduced downtime directly correlates to increased production efficiency, as the uninterrupted flow of compressed air ensures that assembly lines keep moving and tools keep working. In manufacturing, where every second counts, the assurance of reliable performance becomes the linchpin in meeting deadlines, fulfilling orders, and maintaining competitiveness.

From precision calibration to consistent pressure delivery, the reliability of screw air compressors transcends industries. Their ability to remain steadfast through the challenges of time and environment renders them as guardians of efficiency, enablers of production excellence, and indispensable assets across sectors.

As the industrial landscape continues to evolve, so does the canvas upon which screw air compressors paint their versatile strokes. The future holds a tapestry of trends and innovations that promise to elevate these compressors from mere workhorses to the vanguards of efficiency and adaptability.

The Pulse of Innovation

The winds of innovation are ushering in an era of smarter, more efficient screw air compressors. Embedded sensors and advanced control systems are transforming these compressors into intelligent entities that respond proactively to changing demands. Predictive maintenance, driven by data analytics, ensures that any potential issues are nipped in the bud, minimizing downtime and optimizing production uptime.

Efficiency Redefined

The future promises a redefinition of efficiency, with screw air compressors leading the way. Variable speed drive (VSD) technology, already a stalwart, will become more prevalent, allowing compressors to dynamically adjust their speed and output based on real-time demand. The convergence of VSD with the Internet of Things (IoT) will foster an environment where compressors seamlessly communicate with other machinery, orchestrating a symphony of efficiency across the factory floor.

Expanding Applications

The versatility of screw air compressors, already impressive, is set to expand further. Industries currently untouched by compressed air solutions may find their doors swung open by innovations that tailor compressors to unique demands. From 3D printing to renewable energy production, these compressors will find new applications, transcending their traditional roles and becoming integral to the success of cutting-edge technologies.

Sustainability at the Core

The future trends in screw air compressors are intrinsically tied to sustainability. As industries double down on their commitment to reduce carbon emissions, these compressors will emerge as allies in this endeavor. Innovations in energy recovery systems will convert waste heat into usable energy, further minimizing the carbon footprint of compressed air production.

As we gaze into the horizon of industrial progress, the future of screw air compressors is nothing short of transformative. Their journey from versatile tools to intelligent, adaptable, and sustainable assets is a testament to the ceaseless march of innovation. These compressors, shaped by emerging trends, are poised to elevate industries toward unprecedented levels of efficiency and productivity.

In the intricate tapestry of modern industrial production, the threads of versatility woven by screw air compressors shine with unparalleled brilliance. As we journey through their remarkable adaptability, several key takeaways emerge, underscoring their significance as indispensable allies across industries.

Screw air compressors emerge as the orchestrators of a symphony of adaptability, seamlessly adjusting their output to meet the dynamic demands of diverse industrial sectors. From automotive manufacturing to food packaging, their ability to harmonize with precision elevates them beyond mere machines, making them integral to the very essence of production processes.

Versatility isn’t just a feature; it’s a catalyst that propels efficiency and innovation forward. The adaptability of screw air compressors ensures that energy is channeled exactly where needed, leading to reduced wastage, minimized downtime, and heightened efficiency. Their embrace of emerging trends, from intelligent control systems to sustainability-focused innovations, heralds an era of progress where innovation and efficiency find a harmonious nexus.

As we bid adieu to this exploration of screw air compressor versatility, it becomes evident that they are much more than mechanical tools—they are champions of the industrial landscape. Their versatility isn’t a singular virtue; it’s a multifaceted gem that drives efficiency, productivity, and innovation. They stand as the embodiment of adaptability in an ever-evolving world, constantly fine-tuning their performance to paint a canvas of operational excellence.

In the grand symphony of industrial production, screw air compressors compose a melody that resonates across sectors, transcending boundaries and challenges. Their adaptability stands as a testament to human ingenuity and engineering prowess, and their legacy is one that elevates industries to new heights of efficiency, productivity, and innovation.