We hope to let you know our screw drive air compressor's advantages and win-win cooperation in the least time.

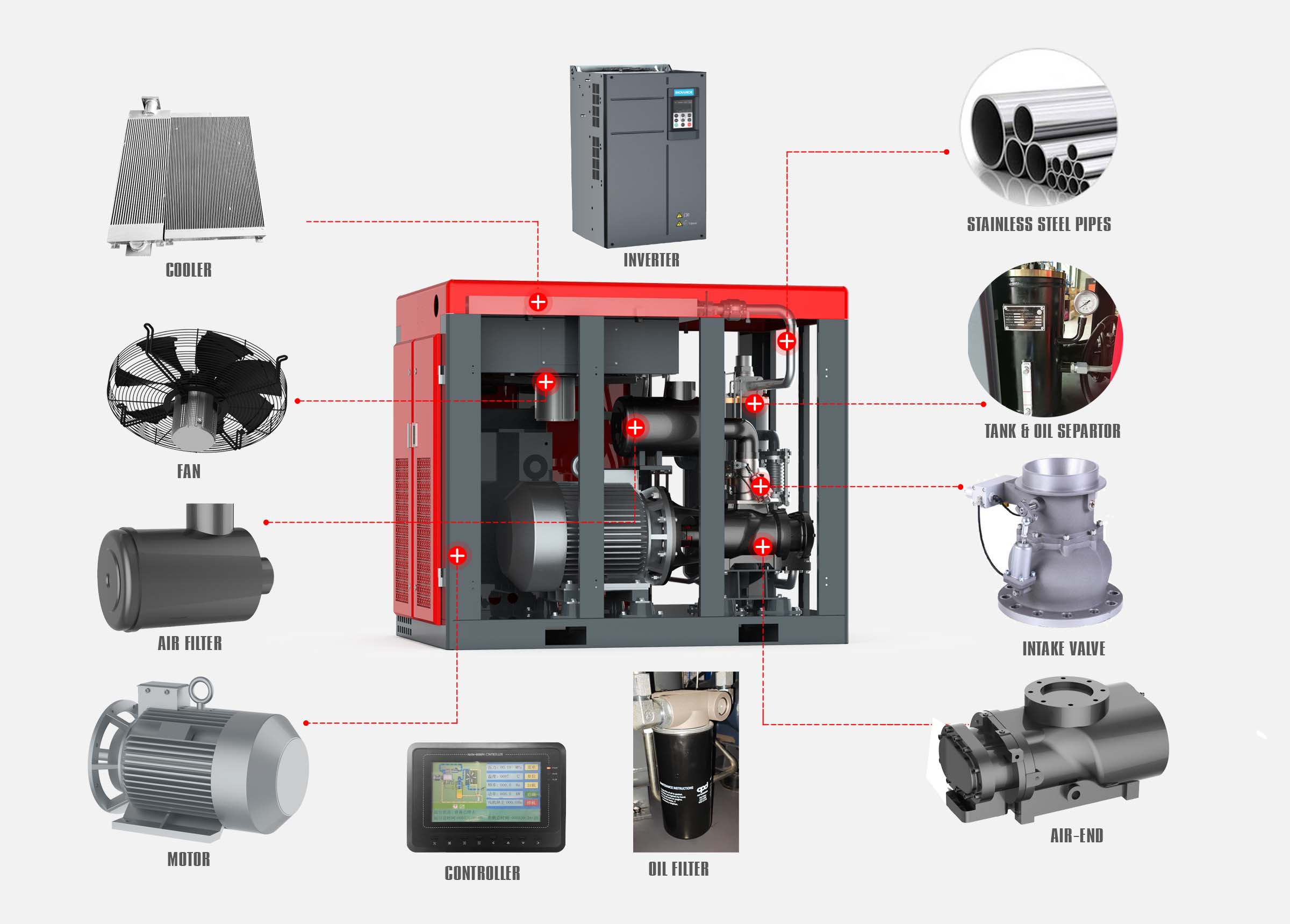

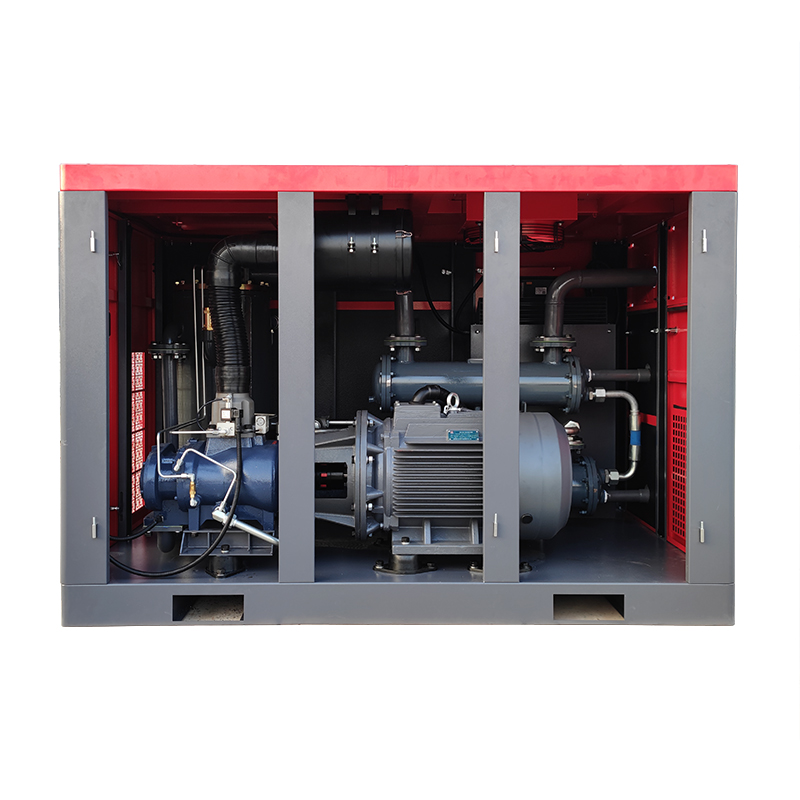

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In the intricate tapestry of modern manufacturing, one pivotal element seamlessly weaves its way through diverse industries: air compressors. These unsung heroes provide the driving force behind a plethora of manufacturing processes, delivering compressed air that powers machinery, tools, and operations.

Among the constellation of compressor types, the screw air compressor shines as a beacon of versatility and efficiency, illuminating manufacturing floors across various sectors.

This article embarks on a journey to uncover the extensive applications and benefits of screw air compressors within the manufacturing sector, shedding light on their indispensable role in shaping the landscape of industrial production.

Air compressors are the silent powerhouses that elevate manufacturing processes to new heights, enabling precision, efficiency, and consistency. From automotive to pharmaceuticals, textiles to food processing, the manufacturing sector relies on these devices to provide the pneumatic energy required for a wide array of applications.

Amid this diverse array of compressors, screw air compressors emerge as stalwarts of adaptability, fueling everything from intricate assembly lines to large-scale industrial operations.

At the heart of the remarkable efficiency of screw air compressors lies their ingenious working principle. These mechanical marvels operate on the principles of positive displacement and rotary motion, resulting in a seamless conversion of mechanical energy into the lifeblood of industrial operations: compressed air.

Screw air compressors operate through a dynamic interplay between precisely engineered rotors housed within a specially designed chamber. As these rotors rotate in opposite directions, the cavities between them gradually reduce in size, entrapping ambient air. This captured air undergoes compression as the rotors continue to rotate, decreasing the volume within the chamber and causing the air to be pressurized.

This mechanical transformation, though intricate, has far-reaching implications for the manufacturing industry. By harnessing this process, screw air compressors generate compressed air, a potent energy source that propels machinery, drives pneumatic tools, and enables a wide spectrum of industrial processes. Compressed air serves as the life force that brings life to automation, precision to assembly, and power to the most intricate operations.

Compressed air finds its applications across a myriad of manufacturing processes. From automotive assembly lines where robotic arms deftly assemble components, to the textile industry where precision air jets weave intricate patterns, compressed air is the common thread that stitches together diverse sectors. It powers pneumatic actuators, pneumatic control systems, and air-powered tools, transforming mundane mechanical tasks into feats of efficiency and accuracy.

However, the importance of compressed air goes beyond its role as a source of power. In certain industries, such as pharmaceuticals and food processing, the quality of the compressed air is paramount. Clean, oil-free compressed air ensures product integrity and prevents contamination. Thus, screw air compressors not only contribute to power-driven processes but also safeguard the quality of end products, further underscoring their multifaceted significance.

As we delve into the intricate mechanisms and profound role of screw air compressors, we begin to grasp their capacity to convert mechanical energy into the lifeblood of manufacturing—compressed air. This essential ingredient propels industries towards operational excellence, driving forward an array of industrial processes with precision, consistency, and the dynamic force of pressurized air.

A Backbone of Versatility

The versatile nature of screw air compressors finds its true essence in the diverse sectors of the manufacturing industry where they wield their transformative power. From heavy-duty industrial processes to precision-driven assembly lines, these compressors weave their influence across a wide spectrum of applications, leaving an indelible mark on the landscape of modern manufacturing.

From Precision to Power: Pervasive Influence

In the manufacturing realm, screw air compressors play a pivotal role in providing the pneumatic energy required to drive a host of machinery, tools, and automated systems. One of their primary applications is in delivering clean, compressed air that fuels pneumatic tools and machinery. By ensuring a steady supply of pressurized air free from contaminants, screw air compressors empower industries to achieve consistent performance and precision in their operations.

Seamless Integration in Operations

Screw air compressors find their place in numerous critical manufacturing processes, leaving their mark on a multitude of industries. In packaging, these compressors power the automated systems responsible for sealing, labeling, and packaging products with speed and accuracy. On assembly lines, they lend the force needed to drive pneumatic actuators that assemble components with unwavering precision, minimizing errors and enhancing efficiency.

Metal Fabrication and Beyond

In the world of metal fabrication, the clanging of metal and the precision of cutting machines are orchestrated by the hum of screw air compressors. The air-driven tools that shape, cut, and weld metal components owe their prowess to the pressurized air supplied by these compressors. The clean and consistent air supply ensures that each cut, each weld, is executed with the utmost accuracy, resulting in finely crafted metalwork.

From Textiles to Food Processing

But the influence of screw air compressors extends beyond metals. In the textile industry, where intricate weaving patterns are brought to life, the air jets responsible for shaping fabrics owe their power to compressed air. Similarly, in the food processing sector, where hygiene and purity are paramount, these compressors provide clean, oil-free air to ensure product integrity and safety.

From power tools to precision-driven automated systems, screw air compressors emerge as a unifying force that powers modern manufacturing. Their versatile applications touch every corner of industry, enhancing efficiency, enabling precision, and propelling sectors towards innovation. In the dynamic dance of manufacturing, these compressors orchestrate the symphony of machinery, offering clean and consistent compressed air—a foundational element that drives the wheels of progress forward.

In the realm of air compressors, screw air compressors stand as a beacon of efficiency and versatility, offering a plethora of advantages over their counterparts. Their unique design and operational characteristics set them apart, rendering them indispensable allies in the manufacturing sector—a domain where precision, efficiency, and consistency are paramount.

One of the standout advantages of screw air compressors lies in their exceptional efficiency. Unlike other compressor types that often incur energy losses due to compression inefficiencies, screw compressors operate with impressive efficiency. Their positive displacement mechanism ensures that each rotation of the rotors contributes to compression, minimizing energy wastage and maximizing the conversion of mechanical energy into compressed air. This efficiency translates directly into cost savings, making screw air compressors the preferred choice for industries keen on optimizing their operational expenses.

In the high-stakes world of manufacturing, downtime is a sworn adversary. Here, screw air compressors step up with their unparalleled ability to operate continuously. Unlike piston compressors that necessitate intermittent cycles, screw compressors run seamlessly without the need for rest intervals. This uninterrupted operation translates into higher productivity, as manufacturing processes can proceed without halts for air compressor cooldown or maintenance.

Precision is the heartbeat of manufacturing processes, and screw air compressors embody this principle admirably. Their ability to maintain a consistent airflow and pressure is a boon for precision-driven operations. In applications where even the slightest deviation can lead to defects or inefficiencies, the stable and uniform output of screw compressors ensures that every pneumatic tool, actuator, or automated process operates with unwavering precision.

In industries where product quality is paramount, the steady supply of clean and consistent compressed air is a non-negotiable requirement. Screw air compressors, with their capacity to deliver such air, become the guardians of quality assurance. By providing oil-free, contaminant-free air, these compressors safeguard the integrity of end products, preventing defects and contamination that could compromise the final output.

In the intricate ecosystem of manufacturing, energy efficiency stands as a linchpin that not only drives sustainability but also directly impacts the bottom line. The symbiotic relationship between energy efficiency and manufacturing costs is a nexus that demands attention, and it’s within this paradigm that the efficiency prowess of screw air compressors shines brightest.

At the heart of screw air compressors’ energy efficiency lies their ingenious design. The positive displacement mechanism, where air is compressed in continuous rotary motion, minimizes energy losses often incurred by other compressor types. This intrinsic efficiency results in more mechanical energy being converted into compressed air with minimal wastage, translating to reduced energy consumption.

The potency of screw air compressors’ energy efficiency is evident through real-world examples that illustrate substantial cost savings. Consider a manufacturing facility burdened with high energy bills due to the operation of outdated compressors. By adopting screw air compressors, this facility experienced a remarkable reduction in energy consumption, leading to significant cost savings over time. Similarly, another case study unveils how a metal fabrication plant minimized its energy expenditure by transitioning to screw air compressors, reaping both financial benefits and environmental gains.

The tales of these case studies reverberate with a consistent theme: the synergy of screw air compressors’ efficiency and manufacturing cost savings. By minimizing energy wastage and optimizing the conversion of mechanical energy into compressed air, these compressors become catalysts for reducing energy consumption, which in turn leads to lower operational costs.

In the heartbeat of manufacturing, reliability is the rhythm that keeps operations in sync. This symphony of efficiency and productivity finds its melody in the reliability and durability of screw air compressors. These mechanical maestros stand as beacons of unwavering performance, offering industries a steadfast companion on their journey towards operational excellence.

Screw air compressors are engineered with durability at their core. Their design, featuring fewer moving parts compared to other compressor types, inherently reduces wear and tear. This intrinsic durability extends their lifespan, ensuring that they endure the demands of continuous operation without faltering. Industries that seek companions for the long haul, capable of withstanding the rigors of industrial environments, find solace in the steadfastness of screw air compressors.

When the spotlight turns to maintenance, screw air compressors confidently take center stage. Compared to their piston counterparts, these compressors require considerably less maintenance. The simplicity of their design and the absence of reciprocating parts contribute to reduced maintenance demands. While piston compressors often necessitate frequent checks, part replacements, and intricate servicing, screw air compressors require minimal intervention, allowing industries to focus their resources on core production activities.

The significance of reduced maintenance and downtime is underscored by its profound impact on production efficiency. In manufacturing, downtime equates to lost opportunities, missed deadlines, and reduced output. By adopting screw air compressors, industries mitigate this risk as their dependable performance and minimal maintenance requirements lead to fewer instances of downtime. The result is an operational ecosystem where machinery hums, processes flow, and production thrives with uninterrupted momentum.

In the realm of manufacturing, air quality transcends being a mere afterthought—it emerges as a cornerstone that shapes both product quality and equipment longevity. Within this paradigm, the role of screw air compressors as purveyors of clean, oil-free compressed air takes center stage, heralding a transformative impact on both production processes and the products themselves.

Screw air compressors are vanguards of air purity. Their design and operational mechanism inherently minimize the presence of contaminants, rendering the compressed air they produce remarkably clean and free of oil residue. This clean air, free from particulates and impurities, becomes the lifeblood that powers machinery, drives pneumatic tools, and propels processes across manufacturing floors.

The impact of clean air is felt profoundly in product quality and equipment longevity. Industries reliant on precise manufacturing, such as electronics and pharmaceuticals, treasure the purity of compressed air. Clean air safeguards against contaminants that could compromise the integrity of products, ensuring that defects are minimized and quality standards upheld. Additionally, by delivering oil-free air, screw air compressors prevent oil contamination within the pneumatic systems, prolonging the life of equipment and reducing the risk of malfunctions.

Clean air isn’t just a badge of product quality—it’s a catalyst for productivity. The absence of contaminants translates into processes that are smooth, efficient, and free from interruptions caused by blockages or malfunctions. With a steady supply of clean, consistent compressed air, equipment operates at its best, minimizing downtime and maximizing output. The result is a manufacturing ecosystem where productivity thrives and defects dwindle, leading to higher yields, fewer rejects, and ultimately, enhanced profitability.

In the intricate mosaic of manufacturing, no two pieces are identical, and the same holds true for the requirements of compressed air. Amidst this diversity, screw air compressors emerge as not just standardized machines, but versatile artisans capable of tailoring their output to suit the exact needs of different industries. Their adaptability and customization prowess stand as a testament to their indispensable role in the tapestry of modern manufacturing.

Screw air compressors transcend the ‘one size fits all’ approach, offering a spectrum of adaptability that aligns with the diverse needs of industries. This adaptability extends beyond their technical specifications to encompass pressure and flow requirements. Whether it’s a high-pressure application demanding power or a low-pressure process requiring precision, these compressors are versatile enough to provide compressed air that suits the nuances of each scenario.

The adaptability of screw air compressors finds its true prowess in their ability to cater to a multitude of industries. For instance, in automotive manufacturing, where precision is paramount, these compressors can be fine-tuned to deliver consistent and accurate compressed air for pneumatic actuators. Conversely, in the textile industry, where air jets weave intricate patterns, the compressors can be configured to provide the necessary airflow with utmost precision.

The true magic of adaptability comes to life when industries demand customized solutions that align precisely with their operational needs. For example, a food processing facility that requires oil-free, contaminant-free compressed air for product safety can benefit from a screw air compressor designed explicitly to meet these requirements. Similarly, an aerospace assembly line could benefit from compressors calibrated to deliver varying pressures for different assembly stages.

In the symphony of modern manufacturing, the melody of efficiency, precision, and adaptability finds its crescendo in the resounding presence of screw air compressors. As we reflect on the expansive applications and transformative benefits they bring to the manufacturing stage, the symphony’s chorus echoes with the harmonious chords of progress and productivity.

From the relentless pursuit of energy efficiency to the mastery of clean and consistent air quality, screw air compressors emerge as virtuosos of manufacturing. Their ability to seamlessly adapt to varying pressure and flow requirements, coupled with their adaptability to a spectrum of industries, underscores their role as pivotal players in the complex dance of production processes.

These compressors aren’t just machines; they’re enablers of manufacturing excellence. Their imprint is felt in the consistent hum of machinery, the precision of assembly lines, and the streamlined processes that define modern production. They become the heartbeat of operational efficiency, the guardians of product quality, and the architects of reduced costs—traits that elevate them beyond mere components to indispensable elements in the pursuit of manufacturing prowess.

As industries chart a course towards manufacturing competitiveness, screw air compressors stand as navigators, guiding the journey with their efficiency, reliability, and versatility. Their efficiency drives cost savings, their reliability ensures uninterrupted workflows, and their versatility adapts to the diverse needs of industries. In the grand tapestry of manufacturing, they weave the threads of progress, enabling industries to achieve not just excellence but the competitive edge that propels them to new heights.

In the realm of air compressor manufacturing, one name stands synonymous with quality, experience, and tailor-made solutions: Sollant. As a leading Turkish manufacturer of air compressors, Sollant has established its prominence through years of dedicated expertise, unswerving commitment to excellence, and a steadfast focus on providing top-notch screw air compressors to industries spanning the spectrum.

With a legacy carved through years of experience, Sollant emerges as a stalwart in the air compressor landscape. Our journey began with a vision to redefine industry standards, to create air compressors that go beyond conventional boundaries and offer a symphony of efficiency, reliability, and adaptability. Through the years, we have honed our expertise, mastering the intricacies of compressor design, operation, and customization to cater to diverse industrial needs.

In the dynamic world of manufacturing, the power of customization reigns supreme. At Sollant, we embrace this ethos wholeheartedly, understanding that no two industries or processes are alike. Our prowess lies in our ability to craft tailor-made solutions that harmonize with the unique demands of each client. Whether it’s a high-pressure application requiring unwavering power or a precision-driven process that demands meticulous airflow control, our screw air compressors adapt seamlessly, delivering excellence that aligns precisely with your requirements.

Our commitment to excellence echoes through every aspect of our operations. From conceptualization to creation, from design to delivery, we uphold the highest standards of quality. Our screw air compressors are not just machines; they are instruments of efficiency, reliability, and innovation that power the engines of industries. With a passion for precision, we ensure that each compressor leaving our facility carries the hallmark of Sollant’s unwavering dedication to excellence.

Sollant’s influence spans borders, transcending geographical boundaries to empower industries around the world. Our customized solutions have left an indelible mark across various sectors, from automotive and electronics to textiles and food processing. This global footprint is a testament to our commitment to supporting industries in their quest for operational excellence.

As we look to the future, Sollant remains driven by innovation, driven by the belief that every challenge is an opportunity to excel. Our commitment to customization, quality, and customer satisfaction remains unwavering. We envision a world where industries thrive, powered by the precision and adaptability of Sollant screw air compressors.

In the symphony of manufacturing, Sollant emerges as a conductor, orchestrating the harmony of tailor-made solutions and industry-leading expertise. With Sollant as your partner, the possibilities are limitless, and the journey towards operational excellence is one that resonates with efficiency, reliability, and the unmistakable cadence of Sollant’s commitment to perfection.