We hope to let you know our advantages and win-win cooperation in the least time.

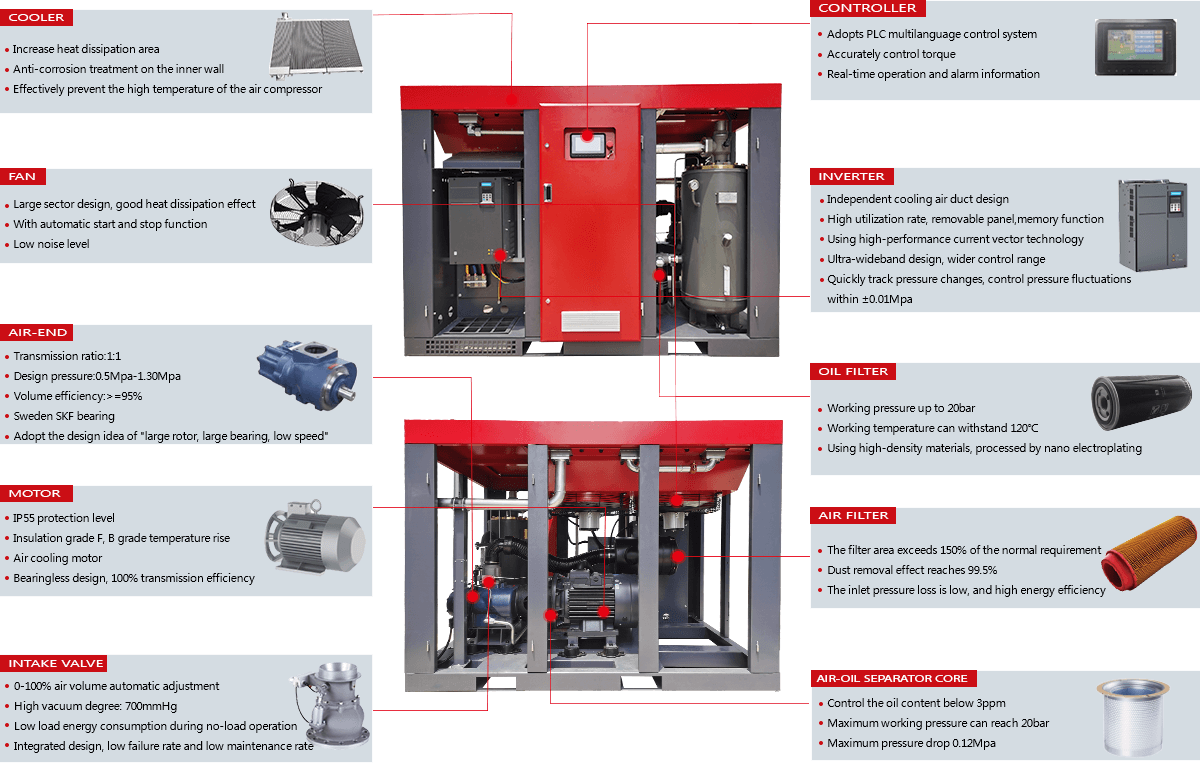

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In an era defined by environmental consciousness and the urgency to combat climate change, the imperative of addressing carbon emissions has taken center stage on the global agenda.

The concept of carbon neutrality, where the net carbon emissions are offset by equivalent removal or reduction, has emerged as a beacon of hope in the battle against the escalating climate crisis. Within this context, industries stand as both contributors to carbon emissions and potential drivers of transformative change.

The repercussions of climate change are felt worldwide, from rising sea levels to extreme weather events, making its mitigation an undeniable global priority. As nations and organizations rally to set ambitious carbon reduction targets, the pursuit of carbon neutrality becomes a linchpin in ensuring a sustainable and habitable future for generations to come.

Industrial sectors, marked by energy-intensive processes, play a significant role in global carbon emissions. The manufacturing, energy, and transportation sectors, among others, contribute substantially to the atmospheric carbon load. As society reimagines its relationship with the environment, industries are challenged to reevaluate their practices and pave the way for more sustainable operations.

Amidst this dynamic backdrop, the focus of this article is to delve into a specific facet of industrial operations that holds immense potential for carbon neutrality: industrial screw air compressors. These unsung workhorses of numerous industries—ranging from manufacturing to construction—have the potential to emerge as champions of sustainable change.

By optimizing their efficiency, integrating renewable energy, and aligning with carbon offset strategies, these compressors can usher industries toward their carbon neutrality goals.

Carbon neutrality, a central tenet in the battle against climate change, revolves around achieving a balance between the carbon emissions released into the atmosphere and their removal or offsetting.

In essence, the goal is to ensure that the amount of carbon dioxide and other greenhouse gases being emitted does not exceed the amount being captured, sequestered, or offset through various means. This equilibrium is pivotal in halting the upward trajectory of global temperatures and the cascading impacts of climate change.

Industries, often characterized by energy-intensive processes and substantial resource consumption, contribute significantly to the world’s carbon emissions. Manufacturing, power generation, and transportation sectors collectively emit a considerable volume of greenhouse gases, with carbon dioxide being a primary offender. The production of goods, the operation of machinery, and the utilization of fossil fuels collectively propel industries’ carbon footprint to alarming levels.

The relentless march of climate change mandates immediate and concerted action, and industrial emissions stand as a critical battleground. The alarming pace of environmental degradation, exemplified by melting ice caps, extreme weather events, and disrupted ecosystems, underscores the urgency of sustainable solutions. The cumulative impact of these emissions is acutely felt, with social, economic, and environmental implications reverberating globally.

In the face of these challenges, the need for sustainable practices within industries becomes undeniable. The integration of innovative technologies, renewable energy sources, and strategic carbon offset initiatives are pivotal to addressing the carbon crisis.

Among these strategies, industrial screw air compressors stand out as a compelling avenue for transformation. By optimizing their efficiency and embracing carbon-neutral practices, these compressors have the potential to redefine industries’ contributions to carbon neutrality and the mitigation of climate impact.

As the world grapples with the consequences of industrial emissions, the exploration of carbon neutrality through the lens of industrial screw air compressors unearths a transformative potential that aligns economic progress with environmental stewardship.

The urgent need for action resonates, demanding industries’ commitment to sustainable solutions that pave the way to a future where carbon neutrality is not merely a concept but a reality that safeguards the planet’s well-being for generations to come.

Industrial screw air compressors have woven themselves into the fabric of modern industries, spanning a diverse range of sectors. From manufacturing plants to construction sites, automotive facilities to food processing units, these compressors find utility in a myriad of applications. Their flexibility, reliability, and consistent performance make them indispensable for generating compressed air that powers various processes, tools, and equipment across industries.

However, the ubiquity of industrial screw air compressors also brings to light an important aspect: their energy consumption. These compressors draw energy from the grid to compress air, and this energy consumption translates into carbon emissions when sourced from non-renewable sources. The electricity required for the operation of compressors contributes to the carbon footprint of industries, adding to the already substantial emissions from energy-intensive processes.

The connection between compressed air production and carbon emissions lies in the energy source that fuels the compressors. Most industrial screw air compressors rely on electricity generated from fossil fuels, which release carbon dioxide when burned. This carbon dioxide is one of the primary greenhouse gases responsible for climate change. Thus, the more energy consumed by compressors, the greater the carbon emissions associated with their operation.

Yet, within this energy consumption lies a significant opportunity for emissions reduction. The efficiency of industrial screw air compressors directly impacts the energy they consume. Optimizing their efficiency translates to lower energy requirements and, consequently, reduced carbon emissions. This optimization can be achieved through various means, such as adopting Variable Speed Drive (VSD) technology, ensuring proper maintenance, and integrating renewable energy sources into their operation.

The realization of emissions reduction through the optimization of air compressor efficiency forms a critical juncture in the journey towards carbon neutrality. As industries harness the potential of these compressors to become energy-efficient, they not only mitigate their carbon footprint but also position themselves as contributors to sustainable progress. This notion of optimizing efficiency as a catalyst for substantial emissions reduction stands as a testament to the transformative capacity of industrial screw air compressors in the broader context of achieving carbon neutrality goals.

The journey towards carbon reduction and sustainable practices finds a crucial ally in the optimization of industrial screw air compressor efficiency. Among the arsenal of strategies, Variable Speed Drive (VSD) technology emerges as a beacon of innovation, offering a transformative solution that not only enhances operational performance but also slashes carbon emissions.

VSD technology reimagines the conventional model of compressor operation. Unlike fixed-speed compressors that run at a constant pace, irrespective of demand, VSD-equipped compressors adapt their speed in real-time to match the required airflow. This agility ensures that compressors operate at the most energy-efficient speed, minimizing wastage during periods of reduced demand.

The crux of VSD’s impact lies in its ability to reduce energy consumption, leading to a direct reduction in carbon emissions. By adjusting the compressor’s speed to precisely meet the demand, VSD systems prevent the unnecessary consumption of energy during low-demand intervals. This intelligent modulation not only saves power but also curtails carbon emissions generated during energy production, contributing significantly to carbon reduction initiatives.

Real-world case studies provide tangible evidence of the power of efficiency enhancement in emissions reduction. A manufacturing facility, for instance, achieved a remarkable 25% reduction in carbon emissions by implementing VSD technology in its screw air compressors. Another industrial complex reported substantial energy savings through the adoption of VSD, leading to a reduction in their overall carbon footprint.

The integration of VSD technology into industrial screw air compressors not only propels efficiency but also underscores their potential as catalysts for carbon reduction. These case studies demonstrate that the optimization of compressor efficiency is not a mere theoretical concept—it yields measurable and impactful results that resonate with sustainability goals.

As industries march towards carbon neutrality, the adoption of VSD-equipped industrial screw air compressors signifies a proactive stride in the right direction. With every watt of energy saved, every kilogram of emissions curbed, these compressors pave the way for a future where efficiency-enhancing technologies work in tandem with environmental responsibility, reshaping the industrial landscape and propelling us closer to a carbon-neutral reality.

The trajectory towards carbon neutrality gains additional momentum through the synergy of industrial screw air compressors and renewable energy sources. The integration of these two pillars not only enhances the operational efficiency of compressors but also ushers in a new era of sustainable compressed air production with minimal carbon impact.

Renewable energy sources, such as solar, wind, and hydropower, stand as the embodiment of clean, sustainable energy. When coupled with industrial screw air compressors, they offer the promise of near-zero or even carbon-neutral compressed air production. By sourcing energy from renewable sources, industries can dramatically curtail carbon emissions linked to compressor operation, aligning their practices with broader sustainability goals.

Numerous industries have embraced the potential of renewable energy integration, transforming their compressor operations into exemplars of carbon reduction. An automotive manufacturing plant, for instance, supplemented its industrial screw air compressors with solar panels, leading to a substantial reduction in its carbon footprint. Similarly, a food processing facility integrated wind-generated energy to power its compressors, aligning its operations with renewable energy aspirations.

The pursuit of carbon neutrality isn’t confined to just emission reduction; it encompasses a broader canvas of strategies that offset and remove carbon from the equation. Carbon offsetting and removal emerge as two complementary approaches that, when harnessed effectively, contribute to the realization of carbon neutrality.

Carbon offsetting involves compensating for carbon emissions by investing in projects that either capture or reduce equivalent amounts of carbon dioxide elsewhere. Industries can support initiatives like reforestation, renewable energy projects, or methane capture, effectively counterbalancing their emissions. This approach allows businesses to play an active role in global carbon reduction efforts while aligning with their own sustainability aspirations.

Industries can effectively achieve emission neutrality by participating in carbon offset projects that directly mitigate the emissions they generate. For instance, a manufacturing facility emitting a certain volume of carbon dioxide can invest in an equivalent amount of renewable energy production or forest conservation. By doing so, they effectively negate their own carbon emissions, thereby aligning their operations with carbon neutrality goals.

While carbon offsetting addresses historical emissions, investing in carbon removal technologies addresses the existing carbon load in the atmosphere. Industries can support innovative projects that capture and store carbon dioxide, preventing its release into the environment. Technologies such as direct air capture and enhanced mineralization not only reduce carbon levels but also bolster sustainability by contributing to the restoration of ecosystems and promoting circular economy principles.

Investing in carbon removal technologies isn’t merely an exercise in environmental responsibility; it’s a strategic alignment with sustainability goals. These investments resonate with the broader agenda of creating a balance between economic progress and ecological health. Industries championing carbon removal technologies not only minimize their carbon footprint but also foster innovation and set an example for responsible and forward-thinking practices.

As industries seek to tread the path of carbon neutrality, the integration of both carbon offsetting and removal strategies becomes an imperative. The partnership between these approaches—offsetting historical emissions and actively removing existing carbon—crafts a powerful narrative of sustainable change. In the pursuit of a carbon-neutral future, industries not only optimize their operations but also transcend their role as carbon contributors, transitioning into agents of transformative environmental stewardship.

In the journey towards carbon neutrality, the potential for collaboration emerges as a powerful catalyst for transformative change. The convergence of industries, compressor manufacturers, and renewable energy providers fosters a synergy that not only accelerates the transition towards carbon neutrality but also establishes an ecosystem ripe for sustainable change.

Industries, driven by carbon neutrality aspirations, can collaborate with compressor manufacturers and renewable energy providers to weave a tapestry of innovative solutions. These partnerships redefine traditional roles, transcending silos and forging a collective pursuit of sustainability. Compressor manufacturers, armed with technological prowess, can tailor solutions that optimize energy efficiency, seamlessly aligning with renewable energy sources.

Partnerships amplify the impact of individual efforts. Industries harness the expertise of compressor manufacturers to tailor systems that maximize energy efficiency, translating to reduced carbon emissions. The integration of renewable energy into compressor operations further chips away at the carbon footprint. The result is a compounding effect—a transition towards carbon neutrality that’s propelled by the combined force of expertise, innovation, and shared intent.

Partnerships thrive in an ecosystem fueled by innovation and guided by supportive policies. Collaboration between industries, manufacturers, and renewable energy providers fosters an environment ripe for groundbreaking ideas. Innovations such as advanced carbon capture technologies, smart energy management systems, and sustainable operational practices are nurtured within this collaborative framework.

Policy support, on the other hand, sets the foundation for sustainable change by incentivizing carbon-neutral practices and providing a regulatory framework for sustainable collaborations. Governments and international bodies play a pivotal role in shaping an environment where industries are encouraged to collaborate, innovate, and champion sustainable practices.

In the heart of Turkey’s industrial landscape, a beacon of innovation and sustainability shines bright—Sollant, a prominent name in the realm of industrial screw air compressors. With a steadfast commitment to producing energy-efficient compressors and contributing to carbon neutrality, Sollant stands as a testament to Turkey’s growing prominence in the global manufacturing arena.

Sollant is not just another industrial equipment supplier; it is a hub of expertise, innovation, and sustainable practices. Situated in Turkey, a country renowned for its rich history and diverse culture, Sollant adds a new dimension to the narrative by exemplifying Turkey’s prowess in modern industry. As a professional manufacturer specializing in industrial screw air compressors, Sollant has etched its name in the global stage, delivering high-quality solutions that transcend borders and industries.

At the core of Sollant’s philosophy lies the unwavering commitment to energy efficiency. The company’s journey is fueled by the understanding that energy-efficient practices are not just environmentally responsible but also economically viable. Sollant’s industrial screw air compressors, meticulously engineered and designed, are a testament to this commitment. By producing compressors that optimize energy consumption while maintaining superior performance, Sollant redefines industry standards.

As the world unites to combat climate change, Sollant stands at the forefront of innovation in carbon neutrality. Acknowledging the imperative to balance carbon emissions, the company has invested in research and practices that contribute to the global carbon offset. With a keen focus on reducing the carbon footprint of its operations and products, Sollant’s endeavors extend beyond industrial excellence to environmental stewardship.

Sollant’s roots in Turkey’s manufacturing prowess go beyond geographical location. The company’s commitment to excellence echoes the long-standing Turkish tradition of craftsmanship and dedication to quality. By upholding Turkish manufacturing standards and embracing cutting-edge technologies, Sollant exemplifies the synergy of tradition and innovation—a hallmark of the Turkish manufacturing legacy.

Sollant, as a pioneering Turkish industrial screw air compressor supplier, embodies the values and aspirations that define modern industry. With a focus on energy efficiency, technological innovation, and contributions to carbon neutrality, Sollant crafts a narrative of a brighter, more sustainable industrial future. Its role as a Turkish manufacturer resonates with the country’s historic legacy while embracing the urgency of global sustainability. As industries worldwide strive for greener practices, Sollant’s commitment to excellence and sustainability serves as an inspiration and a guiding light in the realm of industrial equipment supply.