We hope to let you know our advantages and win-win cooperation in the least time.

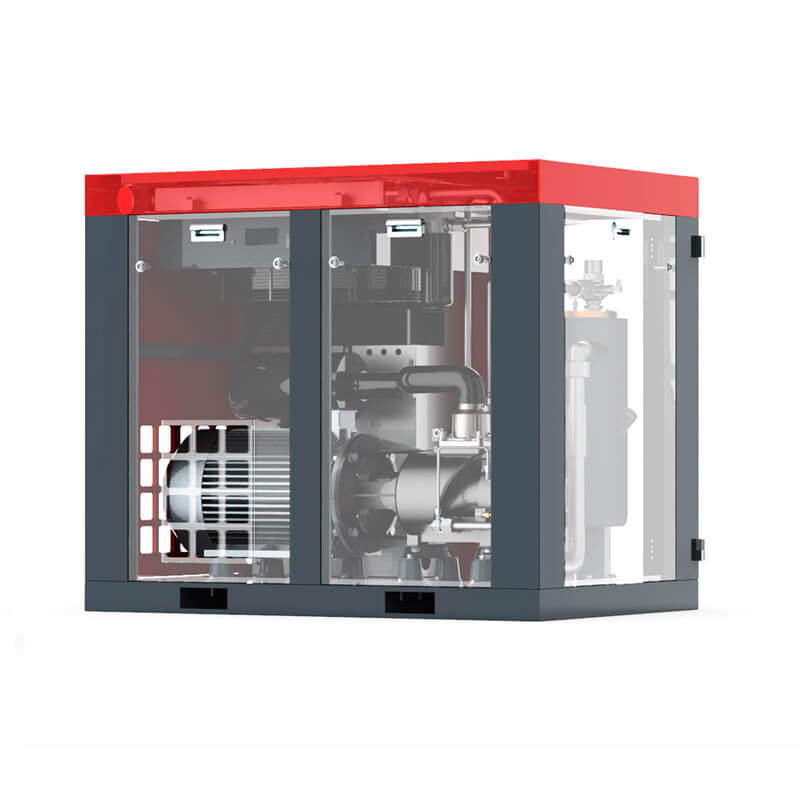

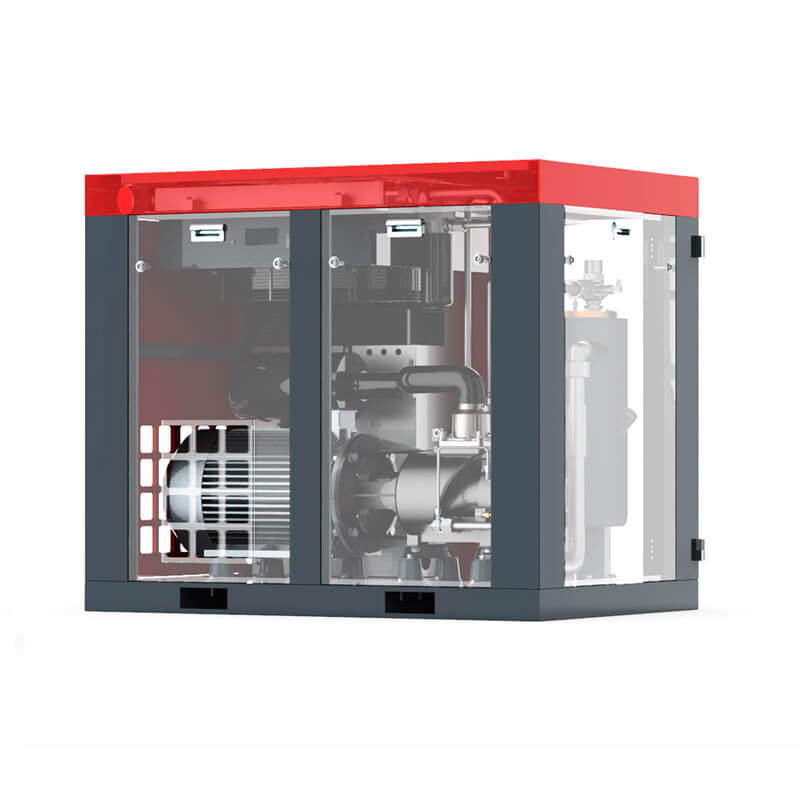

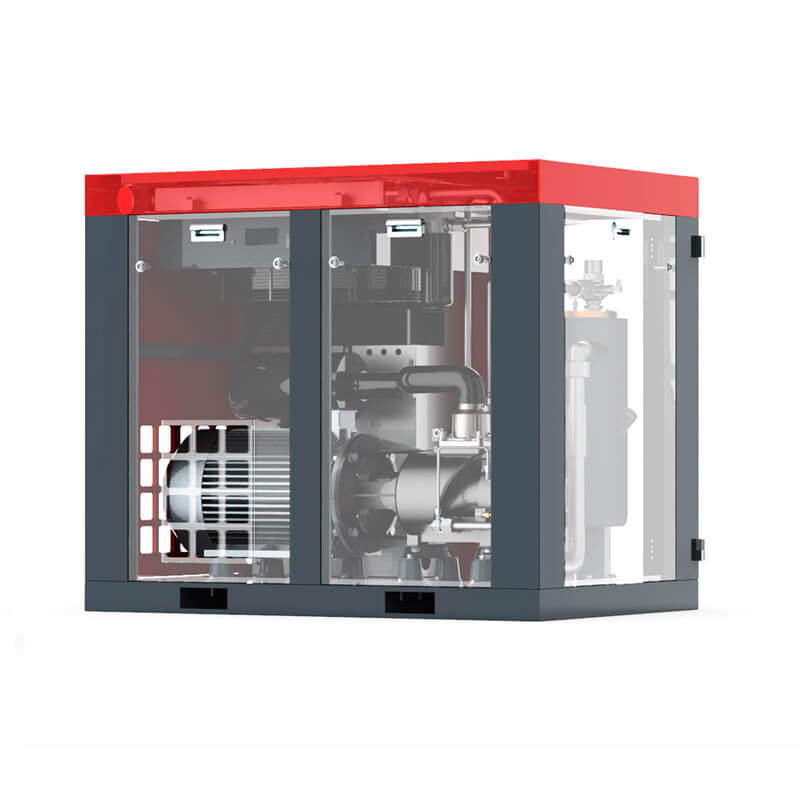

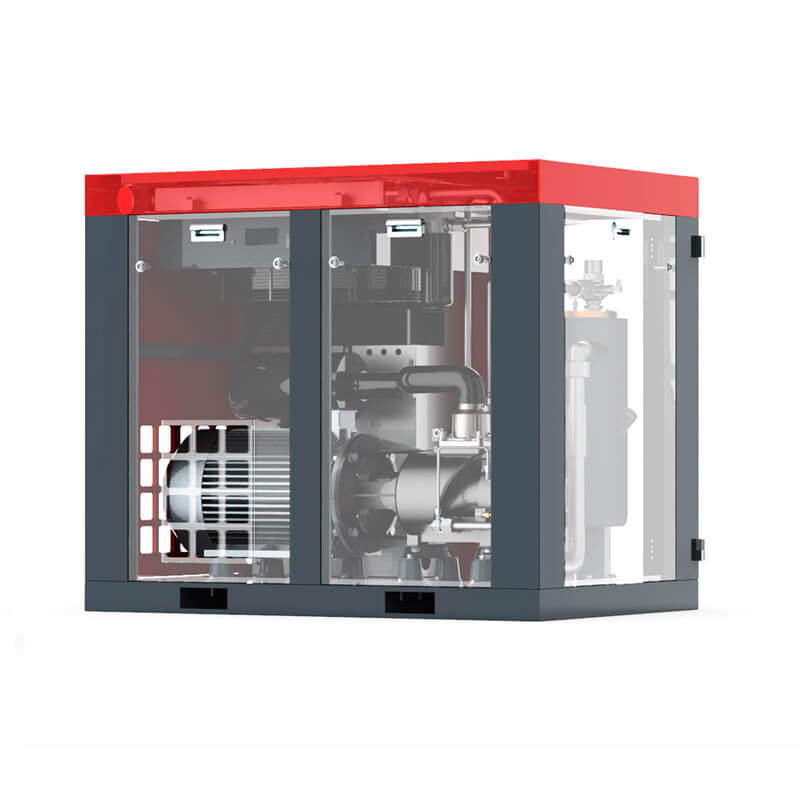

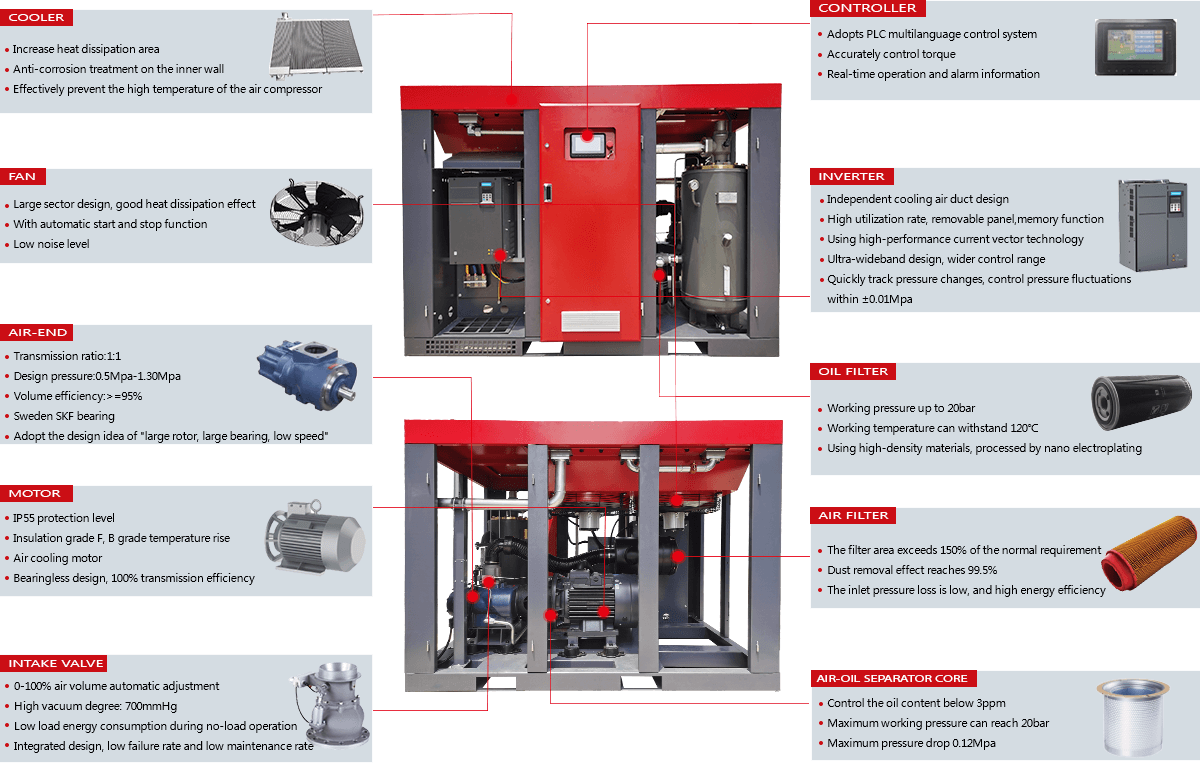

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In the dynamic realm of modern industry, energy consumption stands as a defining factor influencing operational efficiency, costs, and environmental sustainability. The utilization of energy resources not only shapes production outputs but also determines the environmental footprint industries leave behind.

A critical player in this landscape is the industrial screw air compressor—a foundational component that powers a multitude of applications across diverse sectors.

Energy is the lifeblood of industrial processes, driving the machinery, equipment, and systems that propel production forward. However, this immense reliance on energy comes at a cost. The consumption of electricity and fossil fuels translates into substantial operational expenses, directly impacting a company’s bottom line. Moreover, excessive energy use contributes to greenhouse gas emissions, exacerbating environmental challenges such as climate change and air pollution.

Industrial screw air compressors, often operating behind the scenes, play a pivotal role in powering numerous applications within industries. From manufacturing to construction, automotive to pharmaceuticals, they provide the essential compressed air needed to operate pneumatic tools, control processes, and facilitate production activities. As silent workhorses, these compressors enable entire production lines to function seamlessly and efficiently.

Compressed air, often referred to as the “fourth utility,” is indispensable in various industrial processes. However, what might seem like a readily available resource comes at a considerable energy cost.

Compressed air production is inherently energy-intensive, and a significant portion of industrial energy consumption can be attributed to running air compressors. This fact underscores the critical importance of understanding and optimizing the energy consumption patterns of industrial screw air compressors.

Several interrelated factors contribute to the energy consumption of screw air compressors:

To illustrate the diversity in energy consumption patterns, statistical data and case studies are invaluable tools. Different compressor models exhibit varying energy consumption profiles based on factors like capacity, design, and technology. For instance, rotary screw compressors equipped with Variable Speed Drive (VSD) technology can dynamically adjust their speed according to demand, reducing energy wastage during off-peak times. Statistical data can quantify energy consumption reductions achieved through optimization strategies, providing a clear picture of the potential for cost savings and environmental impact reduction.

Real-world case studies further underline the significance of energy consumption analysis. These studies showcase scenarios where businesses successfully lowered energy consumption by adopting energy-efficient compressor solutions, demonstrating the tangible benefits of optimization.

By scrutinizing these energy consumption patterns and understanding the underlying factors, industries can make informed decisions regarding compressor selection, operation, and optimization. This knowledge empowers them to take proactive measures in curbing excessive energy use, ultimately contributing to lowered operational costs and an ecologically responsible industrial landscape.

High energy consumption within industrial operations presents a set of formidable challenges that extend beyond the confines of the balance sheet. While energy is an essential driver of production, excessive usage carries profound implications for both businesses and the environment.

One of the immediate challenges of high energy consumption is the strain it places on operational budgets. Escalating energy costs directly translate into inflated operational expenses, denting profit margins and impeding competitiveness. As energy expenses soar, companies find themselves grappling with a financial burden that restricts investment in innovation, growth, and workforce development.

Beyond the realm of economics, the environmental consequences of high energy consumption cast a shadow of global concern. The vast majority of energy production relies on fossil fuels, which release greenhouse gases when burned. Excessive energy usage intensifies these emissions, accelerating climate change and contributing to the degradation of ecosystems. The ecological impacts are far-reaching, from rising sea levels to extreme weather events.

In the face of these challenges, the need for energy-efficient solutions becomes clear. By curbing energy consumption, industries can simultaneously address operational costs, environmental impact, and sustainability. Recognizing this imperative, forward-thinking companies are actively seeking strategies to optimize their energy use, and this search often leads to one key player: industrial screw air compressors.

The challenges posed by high energy consumption are multifold, impacting both economic viability and global environmental stability. As industries grapple with the repercussions of their energy use, the spotlight turns to innovative solutions that can drive transformation.

By embracing energy-efficient practices and technologies—such as those available through optimized industrial screw air compressors—industries can navigate these challenges while fostering a more sustainable future for themselves and generations to come.

In the quest for enhanced energy efficiency, industrial operations are turning to innovative solutions, and Variable Speed Drive (VSD) technology has emerged as a game-changer. This technology offers a dynamic approach to optimizing the energy consumption of screw air compressors, addressing the challenge of variable air demand.

At the heart of VSD technology lies the ability to precisely match compressor output to air demand in real-time. Unlike traditional fixed-speed compressors that run at constant speed regardless of demand, VSD systems enable compressors to vary their rotational speed. This means that during periods of low air demand, the compressor slows down, reducing energy consumption and minimizing wastage. Conversely, when demand surges, the compressor accelerates to meet the requirement efficiently.

One of the key advantages of VSD technology is its ability to prevent energy wastage during low-load periods. In traditional compressors, the on-off cycling during such periods results in energy inefficiency as the compressor expends energy to restart repeatedly. With VSD-equipped compressors, the gradual adjustment of speed ensures a smooth transition, eliminating energy spikes and maintaining optimal efficiency even at low air demands.

The potential energy savings achieved through VSD technology are substantial. By reducing energy consumption during low-load periods and adapting to varying demand, industries can achieve remarkable reductions in their overall energy bills. The energy savings translate into direct cost savings, enhancing the financial viability of energy-efficient practices.

Furthermore, the return on investment (ROI) associated with adopting VSD technology is often swift. The reduced energy bills and increased operational efficiency offset the initial investment in VSD-equipped compressors. Over time, these compressors prove themselves as assets that not only enhance energy efficiency but also contribute positively to the company’s bottom line.

Within the intricate web of achieving energy efficiency in industrial operations, regular maintenance stands as a linchpin. The symbiotic relationship between maintenance practices and energy efficiency is undeniable, as the state of equipment directly influences energy consumption.

Routine maintenance plays a pivotal role in preserving the energy efficiency of screw air compressors. One of the primary culprits of energy wastage is air leaks—a silent but significant contributor to increased energy consumption. Regular maintenance inspections and repairs are crucial for identifying and rectifying air leaks promptly, preventing the unnecessary loss of compressed air and energy.

Well-maintained components translate into optimized performance, and this holds true for screw air compressors as well. Regular maintenance ensures that components like filters, belts, and lubrication systems are operating at their best. A well-lubricated compressor, for instance, reduces friction, minimizes energy loss, and extends the overall efficiency of the system.

The connection between maintenance and energy efficiency extends beyond short-term gains. By adhering to a rigorous maintenance schedule, industries can extend the operational life of their compressors. This prolonged equipment life maintains consistent efficiency levels, mitigates the need for premature replacements, and prevents the energy-intensive process of producing new equipment.

The impact of proactive maintenance on energy efficiency is vividly illustrated through real-world case studies. These studies showcase scenarios where companies implemented stringent maintenance routines and reaped the benefits of sustained energy efficiency. For instance, a manufacturing facility reduced its energy consumption by 15% through regular maintenance practices that included leak detection and component checks.

The narrative of maintenance practices and energy efficiency is one of care and vigilance. Industries that prioritize maintenance reap the rewards of optimized performance, reduced energy wastage, and prolonged equipment life. As case studies illustrate, these practices yield tangible results in the form of cost savings and environmental impact reduction. By nurturing their equipment through meticulous maintenance, industries make a significant contribution to the dual goals of operational excellence and sustainability.

While the efficiency of individual components like screw air compressors is crucial, achieving maximum energy efficiency demands a holistic approach. Integrated system approaches encompass optimizing the entire compressed air system, from its generation to its final utilization.

Proper system design is at the core of integrated approaches. By meticulously planning the layout and components of the compressed air system, industries can minimize energy losses and enhance overall efficiency. This encompasses selecting the appropriate compressor size, optimizing pressure levels, and designing efficient piping layouts that reduce pressure drops.

Efficient piping layouts play a vital role in minimizing energy losses due to friction and leaks. The reduction of pressure drops throughout the system ensures that the energy expended by the compressor is effectively transmitted to the intended end uses. Additionally, effective air treatment—removing moisture, contaminants, and impurities—further enhances system efficiency by preventing damage to equipment and preserving air quality.

Industries that have embraced integrated system approaches bear witness to their effectiveness. In the automotive sector, for example, a leading manufacturer reduced its energy consumption by 20% by revamping its compressed air system design and implementing energy-efficient equipment. Similarly, food processing facilities have achieved substantial savings by optimizing their entire compressed air network, including compressor operation, air treatment, and distribution.

Integrated system approaches offer a paradigm shift from viewing components in isolation to embracing a comprehensive, interconnected strategy. By optimizing not only the compressor but also the entire compressed air ecosystem, industries can achieve unparalleled energy efficiency. This synergy between design, equipment selection, piping layouts, and air treatment results in substantial energy savings and operational cost reductions.

As industries continue to adopt these holistic approaches, they march toward a future where energy efficiency is not only a goal but an integrated reality that powers sustainable and responsible operations.

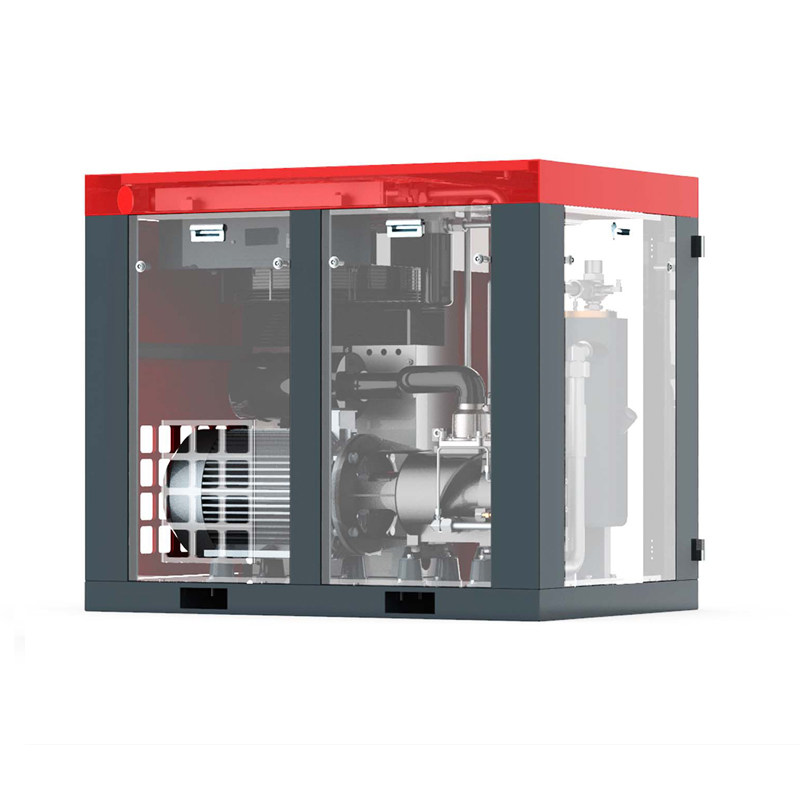

Sollant stands as a dedicated manufacturer specializing in the production of cutting-edge screw air compressors, offering a comprehensive range of products and services that cater to diverse industrial needs. With a commitment to quality, innovation, and sustainability, Sollant emerges as a leader in the field, providing not only efficient compressors but also unparalleled technical support and after-sales service.

Products and Service Spectrum

Sollant’s product lineup spans a wide array of screw air compressors, encompassing various models, specifications, and applications. From rotary screw compressors to oil-injected and oil-free variants, Sollant’s offerings cater to industries as diverse as manufacturing, automotive, construction, and more. As a customer-centric entity, Sollant extends its service beyond the point of purchase, offering comprehensive after-sales support, technical guidance, and expertise. The company takes pride in ensuring that its clients receive not just products but also solutions that seamlessly integrate into their operations.

Manufacturing Expertise and Technological Advantages

With a foundation built on manufacturing expertise and technical innovation, Sollant leads the way in producing state-of-the-art screw air compressors. The company leverages a wealth of professional knowledge and cutting-edge production processes to craft compressors that stand as benchmarks of quality and efficiency. Sollant’s commitment to technological advancement is evident in its ongoing investment in research and development, collaborating with strategic partners to pioneer new solutions and elevate industry standards.

Quality and Certification

Quality is at the heart of Sollant’s ethos. The company is dedicated to delivering products that not only meet but exceed international standards and customer expectations. Sollant’s commitment to excellence is reflected in its adherence to stringent quality control processes, ensuring that every compressor leaving its facilities is a testament to precision engineering. Possible certifications, such as ISO standards, underscore Sollant’s commitment to delivering products of unmatched quality.

Towards Sustainable Development

Sollant’s journey doesn’t stop at innovation; it extends to embracing sustainable practices that resonate with the needs of our planet. Recognizing the imperative of energy efficiency and environmental responsibility, Sollant embeds sustainability into its manufacturing processes. From energy-efficient production methods to eco-friendly initiatives, the company strives to reduce its carbon footprint and contribute positively to the environment. Sollant also actively engages with local communities, fostering a spirit of collaboration and giving back.

Global Markets and Clientele

Sollant’s footprint spans the globe, with its products finding homes in various corners of the world. The company’s global reach is a testament to its commitment to providing quality solutions that transcend geographical boundaries. Sollant values collaboration, welcoming international partnerships and serving a diverse clientele that spans industries and sectors.

In the realm of industrial air compressors, Sollant’s name shines bright as a symbol of quality, innovation, and sustainability. With a comprehensive range of products, unwavering commitment to customer service, and a vision for a greener and more efficient future, Sollant stands as a trailblazer in the industry, leading the way towards a more sustainable and technologically advanced industrial landscape.