22kw screw rotary compressor can be applied to various industries.

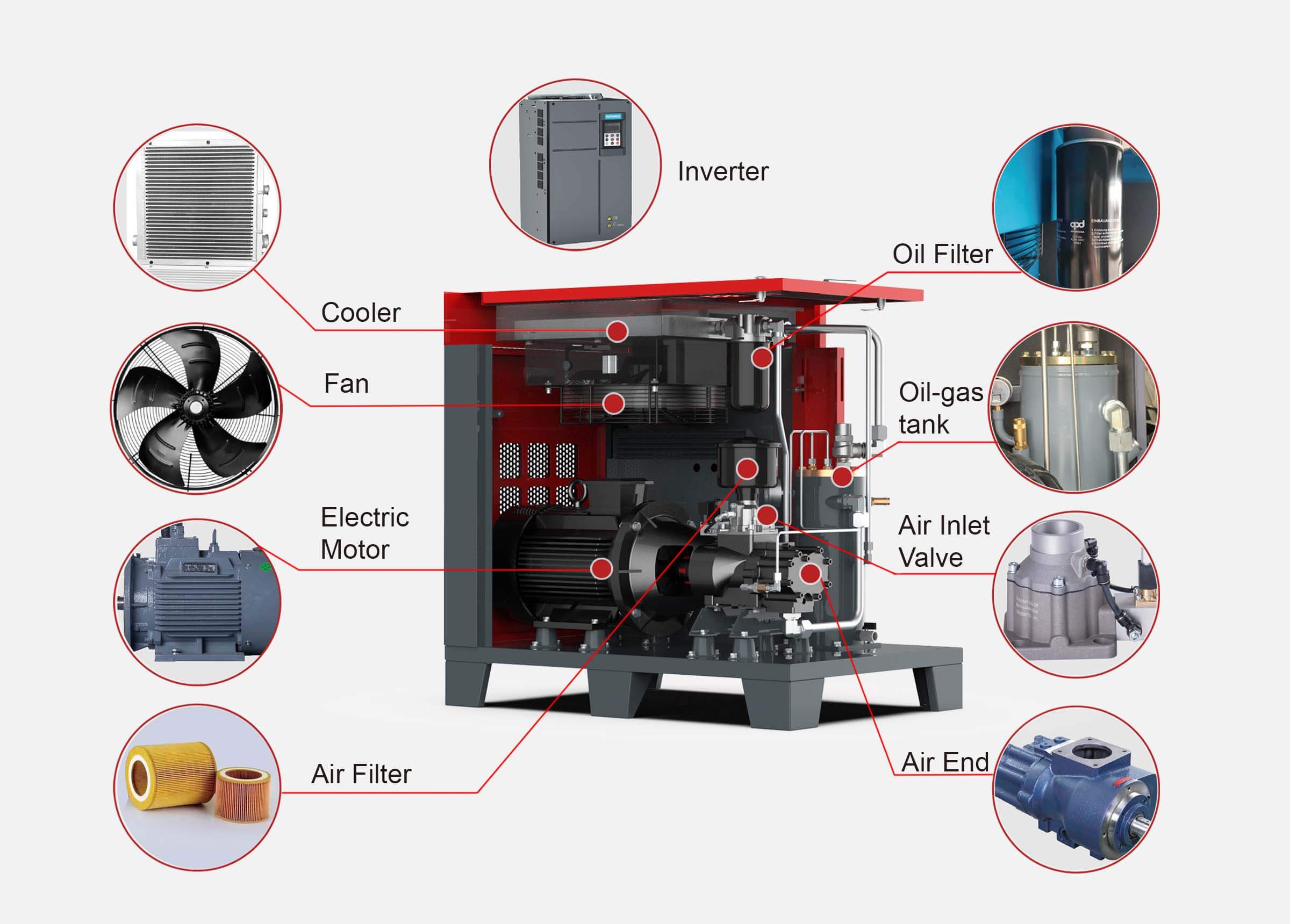

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In an era characterized by growing environmental concerns and a collective commitment to ensuring a harmonious coexistence with our planet, the concept of sustainable development has risen to the forefront of global discourse.

This paradigm shift emphasizes the need to meet the present generation’s needs without compromising the ability of future generations to meet their own. As industries stand at the crossroads of progress and environmental responsibility, the significance of sustainable practices cannot be overstated.

Modern industrial landscapes are undergoing a transformative journey, redefining success not solely in terms of economic growth, but also in terms of ethical and environmental accountability. As corporations and manufacturers seek to align their operations with principles that safeguard natural resources and reduce ecological harm, the role of innovative technologies becomes pivotal.

This is where industrial screw air compressors step onto the stage, offering a prime example of how advancements in engineering can directly contribute to sustainable development.

Industrial screw air compressors represent a technological marvel that has revolutionized the way compressed air is generated across diverse sectors. Operating on the principles of positive displacement, these compressors utilize a pair of interlocking rotors to efficiently compress air and deliver a continuous supply of pressurized air. The rotors, typically helical in shape, rotate within a housing, progressively reducing the volume of air and subsequently increasing its pressure.

The working principle of industrial screw air compressors is rooted in their unique rotary mechanism. As the rotors interlock and rotate, air is drawn into the compressor through the inlet. The air is then trapped between the rotor lobes and the housing, and as the rotors continue to rotate, the trapped air is compressed and discharged through the outlet. This continuous process ensures a steady and consistent supply of compressed air without the pulsations characteristic of other compressor types.

The versatility of industrial screw air compressors is evidenced by their wide-ranging applications spanning industries such as manufacturing, construction, automotive, food and beverage, pharmaceuticals, and more.

Their ability to deliver a continuous stream of compressed air at a constant pressure makes them suitable for operations that demand consistent air supply. From powering pneumatic machinery and tools to facilitating automated processes, screw air compressors play a fundamental role in enhancing productivity and efficiency across the industrial spectrum.

The prevalence of industrial screw air compressors in various industries can be attributed to their efficiency, reliability, and continuous operation. Manufacturers rely on them for their ability to maintain a steady and uninterrupted air supply, reducing production bottlenecks and ensuring consistent quality. Additionally, their compact designs and quiet operation allow them to be integrated seamlessly into diverse work environments.

In a world where energy efficiency and environmental responsibility are paramount, industrial screw air compressors offer a compelling solution. Their efficient operation translates into reduced energy consumption and, consequently, lower greenhouse gas emissions. As industries increasingly prioritize sustainable practices, these compressors have emerged as invaluable tools that align with the ethos of responsible industrial growth.

Industrial screw air compressors have garnered attention for their exceptional energy efficiency, positioning them as a preferred choice for environmentally conscious industries. Their design principles, including the continuous compression process and streamlined rotor profiles, minimize energy losses associated with start-stop cycles.

This efficiency is further enhanced by advanced control systems that adjust compressor output to match demand, avoiding unnecessary energy consumption during periods of lower air demand.

The inherent energy efficiency of industrial screw air compressors directly translates into lower electricity consumption. Unlike traditional compressors that experience energy-intensive start-up sequences, screw air compressors maintain a constant level of operation, reducing the need for power surges. This not only leads to significant energy savings but also optimizes the utilization of electrical resources within industrial settings.

The correlation between reduced energy usage and a decreased carbon footprint is a pivotal aspect of sustainability. By choosing industrial screw air compressors designed for energy efficiency, industries can significantly diminish their greenhouse gas emissions. The lowered electricity consumption directly results in fewer fossil fuels being burned to generate power, subsequently reducing the release of carbon dioxide and other pollutants into the atmosphere.

As industries transition towards low-carbon and sustainable practices, the role of energy-efficient technologies like screw air compressors becomes crucial. Every unit of energy saved contributes to the broader goal of mitigating climate change and conserving natural resources. In industries where compressed air is a fundamental requirement, opting for efficient compressors is an actionable step towards aligning business operations with eco-friendly practices.

In conclusion, the design and operational characteristics of industrial screw air compressors exemplify their commitment to energy efficiency. By embracing these compressors, industries not only harness enhanced operational performance but also play an active role in reducing their environmental impact.

As the world continues to grapple with environmental challenges, these compressors represent a tangible solution that bridges the gap between industrial growth and sustainability.

Industrial screw air compressors are meticulously engineered to address one of the common challenges in compressed air systems: air leakage.

Air leakage occurs when compressed air escapes from the system before reaching its intended point of use, resulting in energy wastage. Screw air compressors employ innovative designs and materials that minimize air leakage points, ensuring that the compressed air reaches its destination efficiently.

Minimizing air leakage is directly tied to ensuring the optimal efficiency of industrial screw air compressors. By preventing compressed air from escaping, these compressors achieve a higher utilization of the energy expended in the compression process. This translates into reduced energy waste and greater overall system efficiency.

In contrast, compressors with high air leakage rates require additional energy input to compensate for the lost air, leading to higher operating costs and environmental impact.

The significance of minimizing air leakage extends beyond energy conservation. By reducing the strain on power generation systems, industrial screw air compressors indirectly contribute to resource conservation and sustainability.

The reduced demand for electricity, driven by enhanced efficiency, lessens the load on power generation infrastructure, resulting in a lowered requirement for fossil fuel consumption and consequent greenhouse gas emissions.

The environmental impact of industrial operations is often intertwined with energy consumption. As screw air compressors actively minimize air leakage and energy wastage, they play a pivotal role in reducing the environmental footprint of industrial processes.

The cumulative effect of reduced energy demand, achieved through efficient compressor operation, contributes to a more responsible use of finite resources and a decreased release of pollutants into the atmosphere.

In industries where compressed air is a driving force behind production, the adoption of industrial screw air compressors takes on greater significance. By choosing compressors that prioritize air leakage minimization and energy efficiency, businesses align their operations with sustainable practices and actively participate in mitigating environmental challenges.

Ultimately, the benefits extend beyond operational efficiency, positively impacting the environment and shaping a more ecologically balanced industrial landscape

Industrial screw air compressors stand out not only for their efficiency and performance but also for their quieter operation compared to other compressor types. The continuous rotary motion of the screw mechanism generates less vibration and noise, resulting in a significantly reduced acoustic footprint. This is a marked departure from traditional piston compressors that are often associated with high levels of noise during their operation.

The reduction in noise emissions from industrial screw air compressors directly contributes to creating more favorable workplace environments. Noise pollution in industrial settings can have a detrimental impact on employee well-being, affecting concentration levels, communication, and overall job satisfaction. By adopting screw air compressors, businesses actively address these challenges and create a quieter, more conducive atmosphere for their workforce.

A quieter workplace is not only conducive to higher productivity but also enhances employee satisfaction and well-being. Excessive noise levels have been linked to increased stress, reduced focus, and even potential health issues over the long term. By choosing industrial screw air compressors that operate at lower decibel levels, employers demonstrate a commitment to the health and comfort of their employees, fostering a positive work environment.

Lower noise levels also have safety implications. In noisy environments, important auditory cues or warnings might be missed, potentially leading to accidents or errors. With quieter compressors, communication becomes easier, and workers are better able to perceive alarms or signals, enhancing overall workplace safety.

Furthermore, noise reduction aligns with broader environmental responsibility efforts. Many regions have noise regulations that industries must adhere to, and choosing quieter equipment can help businesses comply with these standards. Reduced noise emissions contribute to a harmonious coexistence with surrounding communities and support a positive corporate image.

In conclusion, the quieter operation of industrial screw air compressors has a profound impact on workplace environments. It enhances employee satisfaction, well-being, and safety while aligning with environmental responsibilities. As businesses strive for operational excellence and a positive corporate culture, the adoption of quieter compressor technology plays a pivotal role in achieving these goals.

Industrial screw air compressors excel in optimizing resource utilization by providing a reliable and constant supply of compressed air. Unlike some compressor types that exhibit pulsations and variations in output, screw air compressors maintain a steady airflow, ensuring a consistent supply of compressed air. This consistent delivery is crucial for industries where uninterrupted compressed air is essential for continuous operations.

The ability of industrial screw air compressors to efficiently meet compressed air demands contributes to minimizing wastage and enhancing production processes. The continuous operation and controlled output of screw compressors prevent the overproduction of compressed air. This is in contrast to certain other compressor types that might deliver more air than required during their on-off cycles, leading to wastage.

By delivering compressed air precisely when and how it’s needed, screw air compressors align production processes with resource efficiency. Whether for running pneumatic machinery or powering automated systems, the reliable and efficient supply of compressed air optimizes energy consumption and resource utilization.

The optimized resource utilization offered by screw air compressors directly addresses energy wastage and production delays. By avoiding the fluctuations in air supply associated with certain other compressors, these efficient machines prevent operational interruptions due to inadequate compressed air. This not only enhances productivity but also prevents the unnecessary consumption of energy that would be expended to compensate for air supply inadequacies.

Efficient resource utilization, as facilitated by industrial screw air compressors, translates into tangible environmental and economic benefits. Reduced energy consumption conserves precious natural resources and minimizes the release of pollutants. Moreover, the avoidance of overproduction ensures that energy is directed towards productive operations rather than wasted on generating excess compressed air.

In industries where every process is scrutinized for its environmental impact and resource efficiency, the adoption of industrial screw air compressors represents a strategic decision that aligns with sustainability goals. By optimizing resource utilization and minimizing wastage, businesses contribute to responsible resource management and pave the way for a greener, more efficient industrial future.

In line with the global shift towards sustainable practices, the integration of industrial screw air compressors with renewable energy sources has emerged as a forward-looking trend. This integration capitalizes on the synergy between advanced compressor technology and clean energy, ushering in a new era of environmentally responsible compressed air generation.

The integration of industrial screw air compressors with renewable energy sources offers a twofold advantage in terms of sustainability. Firstly, it reduces the carbon footprint associated with compressed air production by utilizing energy derived from renewable sources such as solar, wind, or hydroelectric power. This clean energy input negates the environmental impact of conventional electricity generation, which is often reliant on fossil fuels.

By harnessing renewable energy for compressed air generation, industries can significantly mitigate greenhouse gas emissions that result from electricity consumption. This aligns seamlessly with the global agenda of reducing carbon emissions and combating climate change. The resulting reduction in environmental harm contributes to a cleaner and healthier planet, further reinforcing the commitment to sustainable development.

The integration of industrial screw air compressors with renewable energy sources not only benefits individual industries but also advances a broader culture of environmental responsibility. It serves as a demonstrable example of how industrial operations can harmonize with ecological concerns. This trend also showcases the adaptability of screw air compressor technology to diverse energy inputs, further enhancing their relevance in the evolving industrial landscape.

While the integration of renewable energy sources with screw air compressors holds immense promise, challenges such as intermittency and energy storage must be addressed. Innovative solutions, including energy storage systems and hybrid configurations, are being explored to ensure a consistent supply of clean energy for compressor operation.

The trend of integrating industrial screw air compressors with renewable energy sources epitomizes the convergence of technological innovation and environmental consciousness. It reflects a proactive response to the urgent need for sustainable energy practices within industries. As businesses increasingly transition towards clean energy solutions, the symbiosis between advanced compressor technology and renewable energy stands as a testament to the power of innovation in shaping a more sustainable future.

Longer Lifespan of Industrial Screw Air Compressors

Industrial screw air compressors are renowned not only for their operational efficiency but also for their extended lifespan. This longevity is a result of their unique design, which minimizes wear and tear due to the absence of frequent start-stop cycles. The continuous operation of screw compressors reduces mechanical stress and thermal fluctuations, leading to fewer instances of component degradation.

Efficient and Continuous Operation

The efficient and continuous operation of screw air compressors directly contributes to their prolonged lifespan. Unlike some compressor types that endure frequent on-off cycles, screw compressors maintain a consistent rotation, resulting in smoother operation and reduced mechanical strain. This operational continuity translates into fewer breakdowns, less wear on critical components, and a longer overall equipment life.

Reduced Need for Frequent Replacements

The extended equipment life of industrial screw air compressors reduces the need for frequent replacements. This has significant implications for resource utilization and waste reduction. In industries where compressor replacements are common, the adoption of screw air compressors contributes to fewer discarded machines, less electronic waste, and a reduced demand for raw materials and manufacturing resources.

Environmental Impact Reduction

The link between equipment longevity and environmental impact reduction cannot be overstated. Frequent replacements not only generate electronic waste but also require additional energy and resources for manufacturing, transportation, and disposal. By opting for industrial screw air compressors, industries actively mitigate these negative environmental outcomes.

Sustainable Business Practices

The extended lifespan of screw air compressors aligns seamlessly with the ethos of sustainable business practices. As companies increasingly adopt circular economy principles, they recognize the value of equipment that serves reliably for extended periods. This not only reduces operational disruptions but also contributes to cost savings and a reduced environmental footprint.

In the dynamic landscape of industrial operations, finding a reliable partner that offers comprehensive solutions for compressed air needs is paramount. Enter Sollant, a leading Turkish manufacturer of industrial screw air compressors, with years of experience, a global footprint, and a commitment to excellence that sets it apart in the industry.

With a legacy of excellence and a reputation for innovation, Sollant has positioned itself as a trusted name in the realm of industrial air compressors. Leveraging its years of expertise, Sollant designs and manufactures top-of-the-line screw air compressors that cater to the diverse needs of industries across the globe. From small-scale operations to large industrial complexes, Sollant’s offerings are tailored to meet the demands of any application.

Sollant’s presence extends beyond borders, with its air compressors exported to multiple countries, showcasing the brand’s global recognition and acceptance. One of Sollant’s core strengths lies in its ability to customize solutions according to specific requirements. Whether it’s designing compressors with unique specifications or engineering solutions for specialized applications, Sollant’s commitment to flexibility ensures that every customer’s needs are met.

But Sollant’s dedication doesn’t end with product delivery. The brand’s after-sales service is marked by its professionalism and dedication to customer satisfaction. With Sollant, customers gain access to a responsive and knowledgeable support team that ensures seamless installation, ongoing maintenance, and prompt assistance whenever needed. This commitment to after-sales excellence solidifies Sollant’s position as a partner that remains by your side throughout the entire lifecycle of the product.

Sustainability is a driving force in today’s industrial landscape, and Sollant is keenly aware of this imperative. The company’s energy-efficient screw air compressors not only offer reliable performance but also contribute to reduced energy consumption and lower carbon footprints. By choosing Sollant’s compressors, industries actively align their operations with environmentally responsible practices, making strides towards a greener future.

In a world where operational excellence and sustainability go hand in hand, Sollant stands as a beacon of quality, innovation, and responsibility. With its one-stop solution approach, dedication to customization, and commitment to after-sales support, Sollant redefines the industrial air compressor landscape. As businesses seek partners that not only meet their compressed air needs but also share their values, Sollant emerges as a choice that goes beyond expectations, powering industries toward a more efficient, productive, and environmentally conscious future.