Where to buy the best rotary screw air compressor? - Sollant, experience compressor manufacturer.

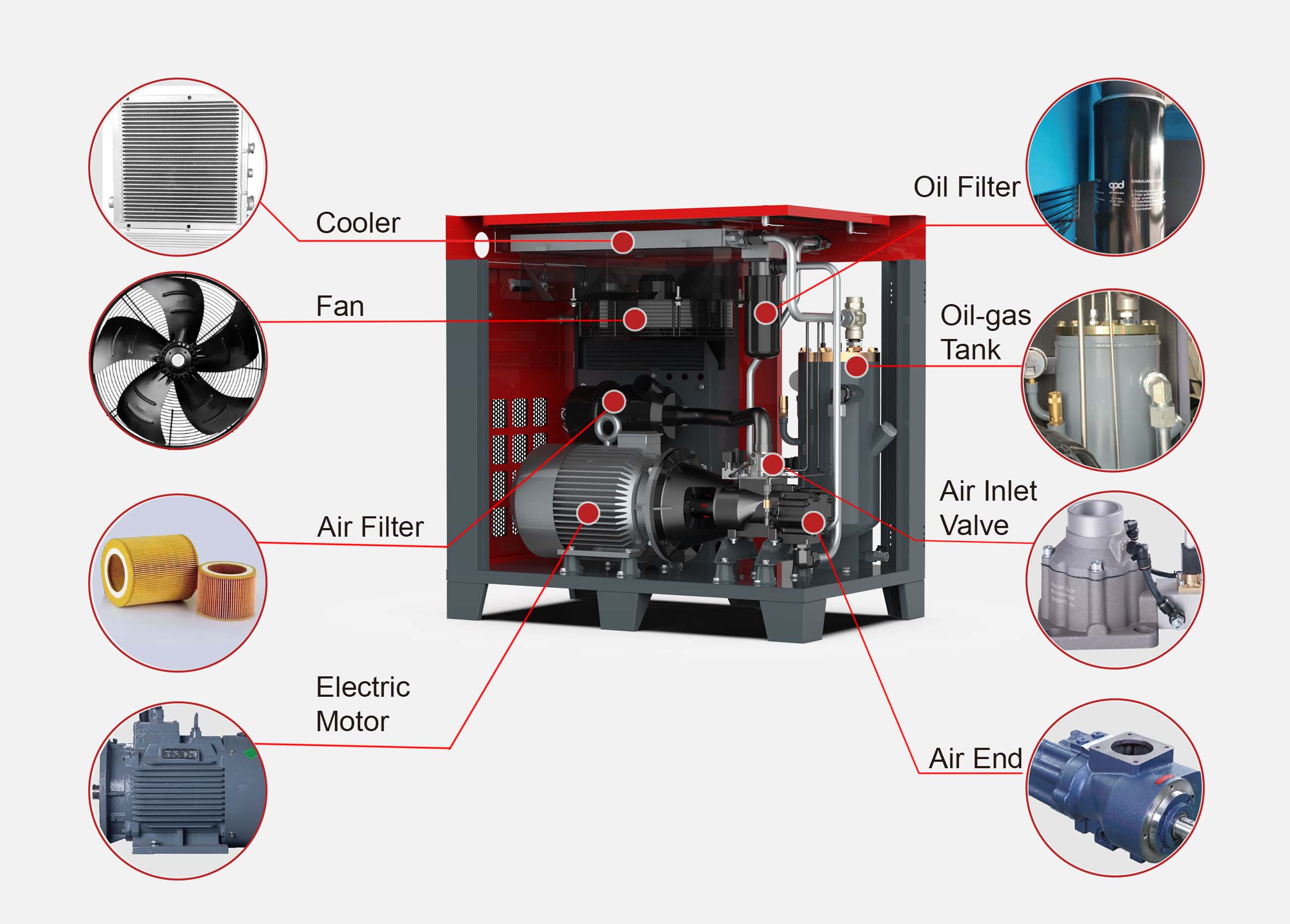

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

Air compressors play a pivotal role across diverse industries, serving as essential tools for generating compressed air used in a wide array of applications. Among the different types of air compressors, screw air compressors and piston air compressors stand out as two prominent choices, each with its unique characteristics and advantages.

In this article, we delve into the significance of these compressor types in various industries and embark on a comprehensive exploration of their performance disparities. Our primary goal is to offer readers valuable insights that will aid in making informed decisions when choosing between screw air compressors and piston air compressors for their specific needs.

In industrial settings spanning from manufacturing and construction to automotive and electronics, the need for a reliable source of compressed air is undeniable. Screw air compressors and piston air compressors, due to their distinct operational mechanisms, find their niche in catering to different demands within these sectors. The significance of these compressors is further emphasized by their contribution to processes involving pneumatic tools, air-powered machinery, and air storage systems.

The aim of this article is two-fold. First, we will conduct a thorough examination of the performance characteristics that differentiate screw air compressors from piston air compressors. By delving into their efficiency, output capacity, air quality, pressure range, and noise levels, readers will gain a comprehensive understanding of the strengths and limitations of each type.

Second, we will provide readers with a valuable selection guide that factors in aspects such as initial investment, long-term operating costs, maintenance requirements, and spatial considerations. Armed with this knowledge, readers will be better equipped to decide whether a screw air compressor or a piston air compressor aligns more closely with their operational requirements and budget constraints.

As industries continue to evolve and technological advancements reshape the landscape of air compression, making informed decisions becomes crucial. By the end of this article, readers will have a clear grasp of the nuances between screw air compressors and piston air compressors, enabling them to select the optimal compressor type that will enhance their productivity and efficiency in their specific industrial contexts.

Screw air compressors operate on a rotary screw mechanism, which involves two interlocking helical rotors within a chamber. As these rotors rotate, air is drawn into the chamber, and the compression process begins. This continuous operation ensures a steady flow of compressed air output without the pulsations characteristic of piston compressors.

The absence of cyclic load fluctuations leads to smoother air delivery, contributing to consistent downstream processes. The constant rotational motion of screw air compressors eliminates the need for valves and minimizes wear, enabling them to operate quietly and efficiently over prolonged periods.

Screw air compressors offer several compelling advantages that make them preferred choices in various industrial applications. One of their key benefits is their exceptional efficiency. The continuous operation and absence of idling cycles result in minimal energy wastage, translating into higher overall efficiency compared to piston compressors. This efficiency is further amplified by the design of the screw elements, which allows for greater compression ratios.

In terms of energy consumption, screw air compressors shine by demanding significantly less power to achieve the same output as piston compressors. Their efficiency not only reduces electricity costs but also contributes to a reduced carbon footprint, aligning with sustainability goals.

Maintenance requirements represent another area where screw air compressors excel. The absence of valves and the reduced number of moving parts decrease the likelihood of breakdowns, thus lowering maintenance costs. Additionally, the operating temperature of screw compressors remains relatively low due to their continuous operation, resulting in less wear on components and longer service intervals. This, in turn, minimizes downtime and production interruptions.

The design of screw air compressors inherently leads to quieter operation compared to piston compressors. The consistent rotation of the helical rotors generates less vibration and noise, creating a more pleasant and conducive working environment.

In summary, the continuous operation feature, higher efficiency, reduced energy consumption, lower maintenance requirements, and quieter performance collectively position screw air compressors as reliable and cost-effective choices for industries where consistent and efficient compressed air supply is paramount.

Piston air compressors, also known as reciprocating compressors, operate based on an intermittent compression process. A piston within a cylinder moves back and forth, drawing air into the cylinder during the intake stroke and compressing it during the compression stroke.

This cyclic operation results in pulsations in the compressed air output, which is a distinctive feature of piston compressors. The intermittent nature of their compression process gives rise to pressure variations in the output, and this can impact downstream equipment or processes that require a steady air supply.

Piston air compressors offer a set of advantages that make them particularly suitable for specific applications and industries. One of their key strengths is their mechanical simplicity. With fewer complex components compared to screw air compressors, piston compressors are relatively straightforward to operate and maintain. This simplicity not only reduces the likelihood of technical issues but also simplifies troubleshooting and repair procedures.

Durability is another hallmark of piston air compressors. The intermittent operation, lower rotation speeds, and robust construction contribute to their extended lifespan. This durability is particularly valuable in industries where rugged and continuous operation is not a requirement, but reliability over time is essential.

Piston compressors are often chosen for smaller-scale applications or environments where a consistent and high volume of compressed air may not be necessary. Their relatively compact size and straightforward design make them suitable for workshops, small businesses, and specific tasks that don’t demand continuous, high-capacity air supply.

Despite the pulsations in their output, piston compressors can often be equipped with accessories or additional equipment to mitigate these fluctuations, making them more compatible with certain downstream processes.

In summary, piston air compressors excel in their simplicity, durability, and suitability for smaller-scale operations. While they might not match the continuous and efficient operation of screw air compressors, their straightforward design, lower upfront costs, and reliability in specific scenarios make them a practical choice for industries with moderate compressed air demands. Understanding their strengths and limitations helps businesses select the right type of compressor for their unique requirements.

When evaluating air compressors for various industrial applications, comparing their efficiency, output capacity, and other performance metrics is essential. Let’s delve into a comprehensive performance comparison between screw air compressors and piston air compressors, considering key factors that impact their suitability for specific tasks.

Efficiency and Output Capacity

Screw air compressors exhibit higher efficiency due to their continuous operation. The absence of idling cycles reduces energy wastage, resulting in more favorable energy consumption compared to piston air compressors. This efficiency advantage becomes particularly pronounced in situations where a consistent air supply is vital.

In terms of output capacity, screw air compressors can deliver a more stable and continuous flow of compressed air at a constant pressure. This trait makes them ideal for applications demanding steady air delivery, such as continuous manufacturing processes or large-scale industrial operations. On the other hand, piston air compressors, with their intermittent operation, might struggle to provide the same level of constant output for extended periods.

Air Quality

Screw air compressors often excel in delivering higher-quality compressed air. The continuous compression process minimizes fluctuations and pulsations, resulting in a more consistent and smoother air flow. This contributes to a lower likelihood of contamination and variations in air quality. Such attributes are crucial in industries like electronics, pharmaceuticals, and food processing, where air quality requirements are stringent.

Piston air compressors, due to their pulsating nature, might introduce more pulsations and variations in air quality. While this might not be a concern in applications where air quality requirements are more lenient, it’s worth considering for industries that demand consistent and contamination-free compressed air.

Pressure Range and Noise Levels

Screw air compressors can often operate at higher pressure ranges with greater efficiency due to their continuous compression mechanism. This makes them suitable for tasks that require higher pressure outputs, such as heavy-duty manufacturing processes or applications involving pneumatic tools.

Piston air compressors, while not as efficient at high pressures, can still cater to lower pressure requirements effectively. They are often used in environments where a consistent but moderate air supply is needed.

In terms of noise levels, screw air compressors generally offer quieter operation due to their continuous rotation, which generates less vibration and noise compared to the cyclic movement of piston air compressors.

Understanding these performance comparisons aids in making informed decisions about which type of compressor is best suited for specific industrial applications. The choice between screw air compressors and piston air compressors should align with the specific requirements of each task, ensuring optimal performance and efficiency.

Choosing between screw air compressors and piston air compressors involves considering their distinct characteristics and aligning them with the requirements of different industries and applications. Let’s explore real-world examples where each type shines, demonstrating their practicality in diverse scenarios.

Screw Air Compressors: Preferred Applications

Piston Air Compressors: Suitable Scenarios

By examining these application scenarios, businesses can discern which type of air compressor – screw or piston – best addresses their specific operational requirements, ensuring optimal performance, energy efficiency, and cost-effectiveness.

Selecting the right air compressor type – screw or piston – involves a systematic evaluation of various factors that align with the specific needs and applications of your industry. To aid in this decision-making process, let’s delve into key considerations that play a crucial role in determining the optimal compressor choice.

Initial Investment and Long-Term Operating Costs

Screw air compressors often require a higher initial investment due to their advanced technology and continuous operation capabilities. While this might be a deterrent for some, it’s important to consider the long-term operating costs. The higher efficiency of screw air compressors leads to lower energy consumption and, subsequently, reduced electricity bills. Over time, the initial investment can be outweighed by the ongoing savings in energy expenses.

Piston air compressors, on the other hand, have a lower upfront cost but might incur higher operating expenses due to their intermittent operation and potentially higher energy consumption. However, for smaller-scale operations with modest air demands, the lower initial investment might make piston compressors a practical choice.

Maintenance Requirements and Service Intervals

Maintenance is a crucial aspect to factor in when selecting an air compressor. Screw air compressors generally have fewer moving parts, reducing the likelihood of breakdowns and minimizing maintenance requirements. Additionally, their continuous operation results in less wear on components, leading to longer service intervals. This translates to reduced maintenance costs and minimized production downtime.

Piston air compressors, while simpler in design, require more frequent maintenance due to the cyclic nature of their operation. Components like valves and piston rings might experience more wear, necessitating more regular upkeep. The higher maintenance frequency should be considered when evaluating the long-term costs associated with piston compressors.

Available Space and Footprint

The physical space available for compressor installation is a practical consideration. Screw air compressors often have a smaller footprint due to their compact design, making them suitable for environments with limited space. Additionally, they can be installed closer to work areas due to their quieter operation.

Piston air compressors might require more space, especially when considering the expansion of air tanks to mitigate the pulsations in their output. Businesses with space constraints might need to explore how effectively they can accommodate piston compressors without disrupting workflow or safety protocols.

Application-Specific Requirements

Ultimately, the selection of the ideal air compressor type should align closely with the specific requirements of your industry and applications. Consider factors like air quality standards, required pressure ranges, and the importance of consistent air supply. Industries where clean and constant compressed air is crucial, such as pharmaceuticals or electronics, might lean towards screw air compressors. In contrast, scenarios involving intermittent or moderate compressed air needs might find piston compressors more suitable.

By thoroughly assessing these considerations, businesses can make a well-informed choice between screw air compressors and piston air compressors, ensuring that the selected compressor type enhances productivity, energy efficiency, and overall operational success.

Maintaining air compressors is essential to ensure their optimal performance, reliability, and longevity. Let’s explore the maintenance procedures for both screw air compressors and piston air compressors, along with the ways regular maintenance contributes to extending their lifespan.

Maintenance Procedures for Screw Air Compressors

Screw air compressors require a comprehensive maintenance approach to keep them running smoothly. Key maintenance tasks include:

Maintenance Procedures for Piston Air Compressors

Piston air compressors have their own set of maintenance requirements to ensure their durability and reliability:

Regular maintenance directly impacts the lifespan of both compressor types. For screw air compressors, consistent oil changes, filter replacements, and heat exchanger cleaning ensure smooth operation and prevent premature wear. This proactive approach extends the lifespan of critical components.

In piston air compressors, proper lubrication and valve maintenance contribute to smooth operation and prevent wear-related failures. Regular inspections catch issues before they escalate, reducing the risk of costly breakdowns.

Both types benefit from routine checks to monitor and adjust operating parameters. By addressing minor issues promptly, businesses avoid larger, more expensive problems down the line.

In conclusion, regular maintenance is the cornerstone of extending the lifespan and ensuring the reliable performance of both screw air compressors and piston air compressors. Through diligent care and adherence to recommended maintenance schedules, businesses can optimize their investment and enjoy years of efficient compressed air supply.

The field of air compressor technology continues to evolve, driven by innovation and the pursuit of enhanced efficiency, sustainability, and performance. Both screw and piston air compressor technologies are experiencing advancements that are shaping their future landscape.

Screw Air Compressor Advancements:

Piston Air Compressor Advancements:

Common Trends:

In conclusion, the future of screw and piston air compressor technologies is marked by a drive toward higher efficiency, sustainability, and connectivity. These advancements not only enhance their individual capabilities but also contribute to the broader goals of energy conservation and environmental responsibility. Staying informed about these trends will empower industries to make strategic decisions as they adopt air compressor solutions aligned with evolving needs.

In the dynamic landscape of air compressor technology, the choice between screw and piston air compressors remains a pivotal decision that profoundly impacts industrial operations. Through the comprehensive comparison presented in this article, the distinctions and advantages of each compressor type have been illuminated, enabling a well-informed decision-making process.

Screw air compressors stand out with their continuous operation, higher efficiency, and capacity for delivering a constant air supply. Their technological advancements, reduced energy consumption, and low maintenance requirements position them as optimal choices for industries requiring uninterrupted, high-quality compressed air. They excel in applications ranging from manufacturing and food processing to medical and pharmaceutical production.

Piston air compressors, characterized by their intermittent compression process, offer simplicity, durability, and lower upfront costs. Their suitability for smaller-scale operations, tasks with moderate air demands, and scenarios where consistent air quality is less critical makes them a valuable option for workshops, small businesses, and specific intermittent tasks.

Selecting the appropriate air compressor type is a decision that must be approached with careful consideration. The specific requirements of your industry, application, and operational needs are paramount. Factors such as efficiency, air quality, pressure range, maintenance demands, and available space play critical roles in determining which compressor type aligns most effectively with your goals.

Choosing the right type ensures optimal performance, energy efficiency, and cost-effectiveness, translating to enhanced productivity and operational success. Moreover, the decision resonates with the broader context of environmental responsibility and sustainability as industries seek to minimize their carbon footprint.

In conclusion, the choice between screw and piston air compressors is not a one-size-fits-all decision. By recognizing the unique attributes of each type and evaluating their compatibility with your industry’s demands, you can make an informed choice that contributes to the seamless functioning of your operations. Whether it’s the continuous efficiency of screw air compressors or the durability of piston air compressors, the final decision should be a well-calculated one that elevates the efficiency and efficacy of your industrial processes.