We hope to let you know our advantages and win-win cooperation in the least time.

11kw Rotary Screw Air Compressor

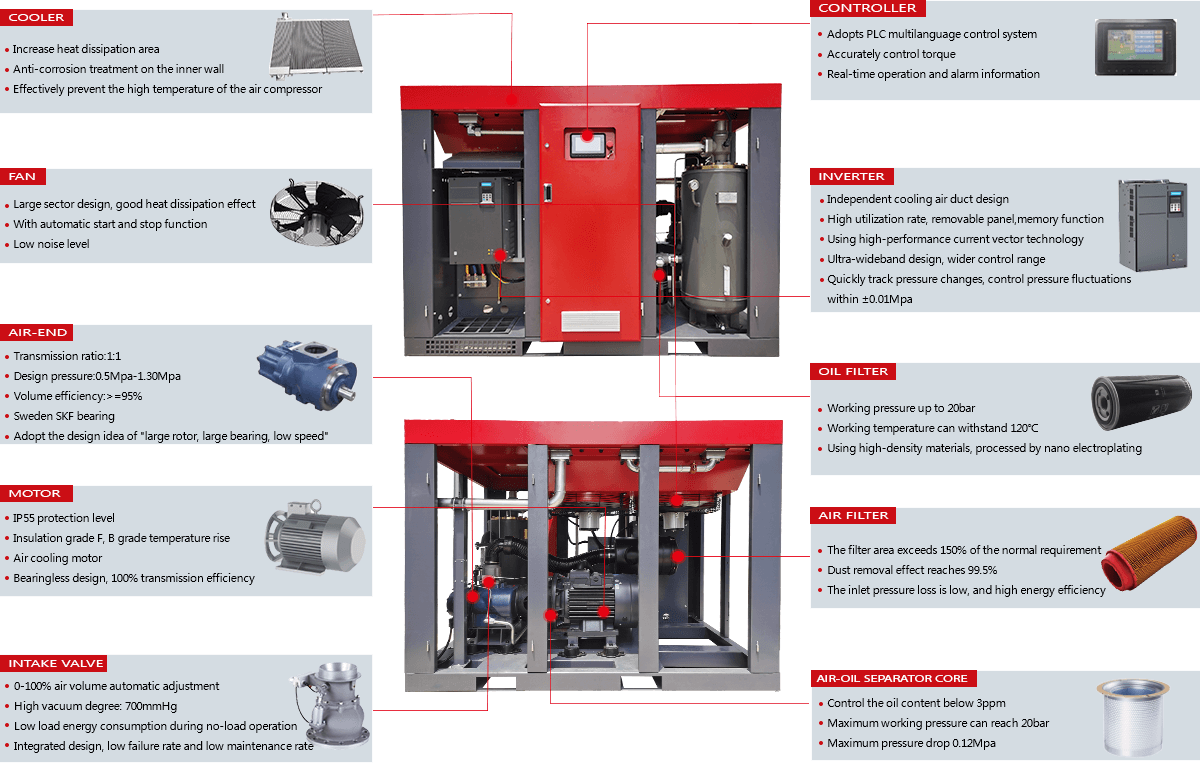

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

Screw air end, high efficiency, low speed, the rotor adopts the third generation 5:6 tooth profile, the world’s best profile design, small size, low noise (only 67db), low energy consumption, low maintenance costs, the best reliability and Usability. The permanent magnet motor and the main engine of the compressor adopt a built-in integrated shaft direct connection structure, the structure is more compact, and the transmission efficiency is 100%. There are no motor bearings, and the rotor with permanent magnets is mounted directly on the protruding shaft of the male rotor, eliminating motor bearing failure points.

The high-efficiency permanent magnet motor makes the rotor rotate through the magnetic field and magnetic force generated by the AC voltage related to the stator coil, with low speed and high efficiency. Compared with ordinary FM motors, the energy-saving performance is superior.

In the ever-evolving landscape of industrial operations, making informed investment decisions stands as a cornerstone of success. Industries around the globe continually seek ways to enhance efficiency, cut operational costs, and boost productivity. At the heart of these aspirations lies the concept of return on investment (ROI), a critical metric that quantifies the financial impact of capital expenditures.

In this article, we delve into the realm of industrial equipment investments, focusing our lens on the intricate world of screw air compressors. These devices, often considered the backbone of numerous manufacturing processes, not only hold the promise of streamlined operations but also present an opportunity for substantial cost savings through enhanced efficiency.

In today’s competitive business environment, every dollar invested must yield tangible returns, both in terms of financial gains and operational improvements. The driving force behind these investments is the desire to optimize operational costs without compromising productivity or quality. The path to achieving this balance often intersects with the quest for efficiency, a factor that not only directly impacts the bottom line but also influences a company’s competitive edge and overall sustainability.

Return on Investment (ROI) serves as a compass guiding businesses through the complex terrain of financial decision-making. At its core, ROI is a performance metric that quantifies the efficiency and profitability of an investment. It provides a clear picture of how effectively a sum of money has been utilized to generate financial returns.

ROI is not just a number; it’s a key that unlocks the door to informed decision-making in the realm of industrial investments.

In essence, ROI is calculated by dividing the net profit gained from an investment by the initial cost of that investment and expressing the result as a percentage. The higher the ROI percentage, the more lucrative the investment is considered.

ROI is a powerful tool particularly relevant in assessing the profitability of equipment acquisitions. When it comes to acquiring industrial machinery, such as screw air compressors, the financial implications are substantial and extend far beyond the initial purchase cost. Factors like energy consumption, maintenance expenses, and operational efficiency play critical roles in shaping the true value of the investment.

ROI provides a standardized framework to measure and compare these factors against the financial returns generated. It guides decision-makers in evaluating whether the investment aligns with the company’s financial goals and growth strategies.

Screw air compressors hold a unique position in the industrial landscape as indispensable workhorses driving various processes across diverse sectors. From manufacturing and construction to healthcare and energy production, these compressors serve as vital components that directly influence operational efficiency and product quality.

ROI takes on added significance in the case of screw air compressors due to their essential role in maintaining optimal production levels while managing energy consumption. Given that these compressors are pivotal to numerous applications, their financial impact resonates throughout an organization. The investment in a screw air compressor extends beyond the initial expenditure, encompassing energy savings, reduced downtime, enhanced productivity, and, consequently, improved profitability.

Calculating the return on investment (ROI) for screw air compressors requires a comprehensive understanding of the various factors that shape the financial outcome. These factors, ranging from initial costs to ongoing operational efficiencies, collectively contribute to the ROI equation.

At the heart of every ROI calculation lies the initial investment cost. This encompasses not only the purchase price of the screw air compressor but also associated expenses, such as installation, setup, and any additional infrastructure modifications. While the initial cost is a significant component, it serves as the foundation upon which subsequent financial outcomes are built.

One of the most substantial variables influencing the ROI of screw air compressors is energy consumption. Compressed air systems are notorious for their energy-intensive nature, and screw air compressors are no exception. The energy consumed by these compressors constitutes a significant portion of the operating costs. Thus, any reduction in energy consumption directly impacts the ROI by reducing ongoing expenses.

Efficiency gains realized through modern screw air compressor technology can lead to substantial energy savings over time. With innovative design and intelligent control systems, newer models of screw air compressors optimize energy usage, ensuring that compressed air is produced only when needed and in the required volume. This energy-efficient operation translates into lower energy bills and, subsequently, higher ROI.

Beyond energy savings, screw air compressors can also impact overall productivity. Their consistent and reliable performance contributes to smoother production processes, minimizing downtime and interruptions. Reduced downtime equates to enhanced operational efficiency, which directly affects the company’s bottom line. By quantifying the value of increased productivity, the ROI calculation becomes a more holistic representation of the compressor’s financial impact.

Calculating the return on investment (ROI) for screw air compressors involves a structured approach that takes into account various financial factors. By systematically evaluating initial investment costs, energy savings, and operational efficiency improvements, you can derive a tangible ROI percentage that reflects the financial impact of your investment.

The formula for calculating ROI is straightforward:

ROI = (Net Profit / Investment Cost) * 100

Breaking down the formula provides a clear understanding of each element:

To calculate the net profit, a crucial step involves assessing the annual energy savings and subtracting them from the annual operating costs. The resulting value represents the net financial benefit derived from investing in a screw air compressor.

Example Calculation:

Let’s consider a hypothetical scenario:

Annual Energy Savings: $15,000

Annual Operating Costs (without the screw air compressor): $40,000

Net Profit = Annual Operating Costs – Annual Energy Savings

Net Profit = $40,000 – $15,000 = $25,000

Once you’ve determined the net profit and investment cost, plugging these values into the ROI formula yields the ROI percentage.

ROI = ($25,000 / Investment Cost) * 100

This percentage signifies the efficiency of the investment, quantifying how much value the screw air compressor is adding to your operations relative to the initial investment.

By following this step-by-step approach, you can precisely quantify the financial impact of investing in a screw air compressor. As we proceed, we will explore the implications of the ROI calculation, how it influences decision-making, and how it guides your path toward optimizing operational efficiency and cost-effectiveness.

In the realm of investment analysis, the concept of the payback period stands as a close companion to the return on investment (ROI). While ROI quantifies the financial gains relative to the initial investment, the payback period provides insight into how long it takes for those gains to cover the initial expenditure.

When applied to the realm of screw air compressors, the payback period unveils the timeline at which your investment transitions from expenditure to net positive value.

The payback period represents the time required for the cumulative savings generated by the investment to equal or surpass the initial investment cost. In other words, it’s the duration within which your financial outlay is “paid back” through operational efficiencies, energy savings, and other benefits derived from the investment.

Let’s delve into an example to illustrate the concept:

Imagine a manufacturing facility that invests $50,000 in a modern screw air compressor. The company anticipates annual energy savings of $12,000 and reduced maintenance costs of $5,000 due to the compressor’s efficiency improvements. The initial investment cost is $50,000, and the expected annual savings total $17,000 ($12,000 + $5,000).

Calculating Payback Period:

Payback Period = Investment Cost / Annual Savings

Payback Period = $50,000 / $17,000 ≈ 2.94 years

In this example, the calculated payback period is approximately 2.94 years. This indicates that it will take around 2.94 years for the cumulative annual savings to match the initial investment cost of $50,000. Beyond this period, the annual savings translate into direct financial benefits for the company.

The payback period provides decision-makers with a tangible timeline for realizing the financial benefits of their investment. A shorter payback period signifies faster recovery and higher returns in a shorter span of time. By juxtaposing the payback period with the ROI, businesses can gain a more comprehensive understanding of the overall financial landscape of their investment in screw air compressors.

Energy savings, often touted as the “low-hanging fruit” of operational efficiency, play a pivotal role in expediting the return on investment (ROI) of industrial equipment such as screw air compressors. As energy costs constitute a significant portion of operating expenses, any reduction in energy consumption directly influences the financial outcome of the investment. In the case of screw air compressors, efficiency improvements translate into tangible financial gains over time.

Quantifying energy savings involves a structured approach to evaluating energy consumption patterns before and after the installation of a screw air compressor. Several methods can be employed to accurately assess the impact of improved efficiency:

Efficiency improvements in screw air compressors lead to reduced energy consumption, which, in turn, translates into financial gains. The process involves converting energy savings into dollars, allowing decision-makers to clearly understand the economic impact of reduced consumption.

Example Illustration:

Suppose a company installs a modern screw air compressor that reduces annual energy consumption by 20%. Given an annual energy cost of $50,000, the reduction in energy consumption amounts to:

Energy Savings = Annual Energy Consumption (Pre-installation) – Annual Energy Consumption (Post-installation)

Energy Savings = $50,000 – ($50,000 * 0.20) = $10,000

This energy savings of $10,000 becomes a direct financial benefit added to the company’s bottom line. When incorporated into the ROI calculation, it enhances the overall financial value derived from the investment in the screw air compressor.

While calculating return on investment (ROI) for screw air compressors offers valuable insights into the financial impact of the investment, it’s essential to acknowledge potential challenges and complexities that can influence the accuracy of these calculations. Understanding these factors enables decision-makers to make informed choices that align with their long-term goals.

Screw air compressors, like any industrial equipment, require regular maintenance to ensure optimal performance and longevity. The associated maintenance costs, while not always immediately evident, play a significant role in shaping the true financial outcome of the investment. An accurate ROI calculation should account for ongoing maintenance expenses, as they directly impact the net financial benefit generated over time.

Considering equipment lifespan is equally crucial. A longer equipment lifespan enhances the potential for extended savings, as operational efficiency and energy consumption improvements persist over the machine’s useful life.

Fluctuations in energy prices can influence the accuracy of ROI calculations. While energy savings are a significant contributor to ROI, variations in energy costs can impact the speed at which the investment pays off. It’s prudent to factor in potential changes in energy prices when projecting savings over the long term.

In the pursuit of accurate ROI calculations, a comprehensive evaluation is essential. Beyond energy savings and operational efficiency, a holistic approach involves considering factors like maintenance costs, equipment durability, and potential changes in energy prices. Decision-makers are encouraged to conduct thorough research, leveraging historical data and projections, to account for these variables effectively.

Consulting experts in the field of industrial equipment and energy efficiency can provide invaluable insights. Experts can assist in developing realistic projections, addressing potential challenges, and ensuring that the ROI calculation is as accurate and comprehensive as possible.

Calculating return on investment (ROI) for industrial equipment, such as screw air compressors, unveils a tapestry of impacts that extend far beyond mere financial metrics.

While ROI offers a tangible measure of financial gains, the broader canvas reveals how increased energy efficiency reverberates across sustainability, environmental responsibility, and the alignment with long-term strategic goals.

Efficiency in energy consumption is intrinsically linked to sustainability and environmental responsibility. By reducing energy consumption, businesses inherently lower their carbon footprint. The ripple effect is substantial: decreased energy demand leads to reduced greenhouse gas emissions, which contribute to environmental preservation and combat climate change. Calculating ROI thus transcends financial returns to encompass a commitment to a greener future.

Investing in efficiency is a testament to a company’s commitment to operational excellence. Efficiency gains translate to streamlined operations, reduced downtime, and optimized production processes. Beyond the immediate financial gains, enhanced operational efficiency positions businesses for long-term growth and resilience.

ROI calculation aligns with the strategic goals of companies aiming for sustainability, growth, and market leadership. The financial benefits realized from energy efficiency investments bolster the organization’s financial health while demonstrating a proactive approach to adapting to evolving industry standards and customer expectations.

The comprehensive impact of ROI extends to stakeholders beyond the organization. Customers, partners, and investors increasingly value businesses that prioritize sustainability and responsible resource management. An investment in efficiency resonates with stakeholders who seek to engage with environmentally conscious enterprises, potentially opening avenues for collaboration, partnerships, and enhanced market positioning.

By highlighting the broader impact of ROI calculations, decision-makers are empowered to view investments through a more comprehensive lens. The financial benefits, while essential, become part of a larger narrative that underscores the role of businesses in shaping a sustainable future.

ROI, in this context, becomes a tool for driving innovation, fostering positive social impact, and contributing to a global movement toward sustainable development.

In the dynamic landscape of industrial manufacturing, the pursuit of innovation and sustainability takes center stage. Amidst this backdrop, Sollant emerges as a prominent Turkish manufacturer, dedicated to the production and research of cutting-edge screw air compressors. With a resolute focus on customer satisfaction and energy efficiency, Sollant spearheads a transformative journey that reshapes the way industries approach compressed air solutions.

A Commitment to Customer-Centricity

At the heart of Sollant’s ethos lies an unwavering commitment to customer-centricity. Recognizing that the needs of industries span across diverse sectors, Sollant tailors its screw air compressors to address specific requirements. From manufacturing facilities to healthcare institutions, Sollant’s comprehensive range of products is engineered to cater to a myriad of applications.

Sollant’s customer-centric approach is underscored by a deep understanding of the challenges that businesses face. Whether it’s optimizing production processes or streamlining energy consumption, Sollant’s solutions are designed to align with the unique goals of each client. This customer-driven mindset ensures that every compressor manufactured by Sollant becomes an integral part of the client’s operational success story.

Elevating Energy Efficiency

One of Sollant’s foremost missions is to redefine energy efficiency within the realm of screw air compressors. Recognizing that energy consumption is a critical concern for industries, Sollant integrates cutting-edge technologies to create compressors that minimize energy wastage. By meticulously designing systems that match air output with actual demand, Sollant’s screw air compressors eliminate inefficiencies associated with fixed-speed models.

The result? A tangible reduction in energy consumption that translates into substantial cost savings. Sollant’s commitment to energy efficiency goes beyond financial gains – it resonates with a larger narrative of environmental responsibility. As industries seek to reduce their carbon footprint, Sollant’s energy-efficient compressors emerge as pivotal tools in achieving sustainability targets.

Innovation and Research-Driven Excellence

Sollant’s journey is marked by a continuous pursuit of innovation and research-driven excellence. The company’s research and development initiatives fuel its capacity to introduce advanced features and functionalities that push the boundaries of compressor technology. From variable speed controls to smart monitoring systems, Sollant’s innovations empower businesses with tools to enhance operational efficiency and accuracy.

This commitment to innovation is reflected in Sollant’s ongoing collaborations with experts in the field. By fostering partnerships with industry leaders and research institutions, Sollant remains at the forefront of technological advancement, ensuring that its products remain relevant and impactful in a rapidly evolving industrial landscape.

Sollant’s journey as a Turkish manufacturer is characterized by a vision that transcends conventional boundaries. By placing customers at the heart of its operations and championing energy efficiency as a core principle, Sollant redefines the potential of screw air compressors. As industries navigate the challenges of the modern era, Sollant stands as a beacon of efficiency and excellence – a partner committed to shaping a sustainable, innovative, and prosperous future for businesses around the world.