Diaphragm compressor is a special structure positive displacement compressor. The cylinder does not need to be lubricated, the sealing performance is good, the compression medium does not contact any lubricant, there is no pollution, and the compression purity can reach 99.999%. It is especially suitable for the compression, transportation, and bottling of high-value rare gases and highly corrosive, toxic, explosive, and radioactive gases. For example, H2、He、Ar、C2H4、F、HS、CL、SiH4、NF

Diaphragm compressor cylinder has good heat dissipation, simple and efficient structure, high pressure can be achieved by two-stage compression, and at the same time, it can be close to isothermal compression. Therefore, it is used in industrial gas, food and medicine, petrochemical industry, aviation nuclear power, military equipment, scientific research, and testing, etc. The field is widely used.

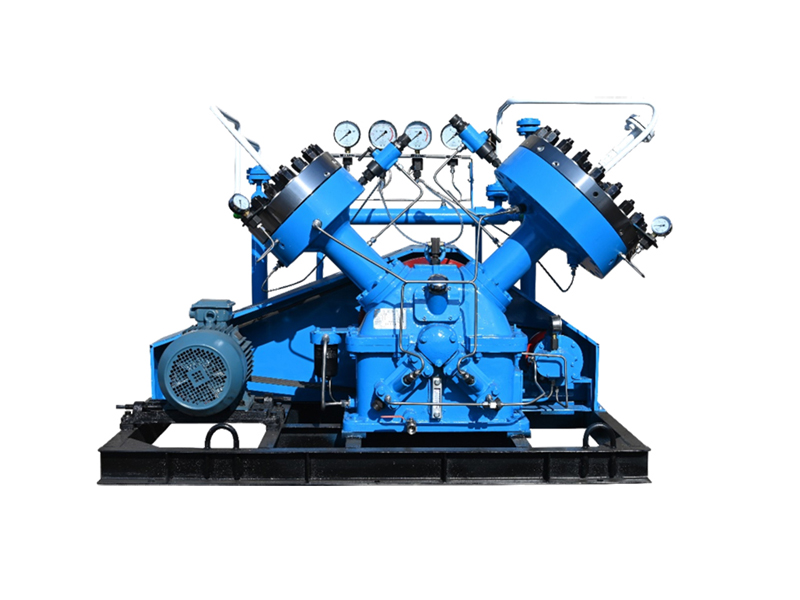

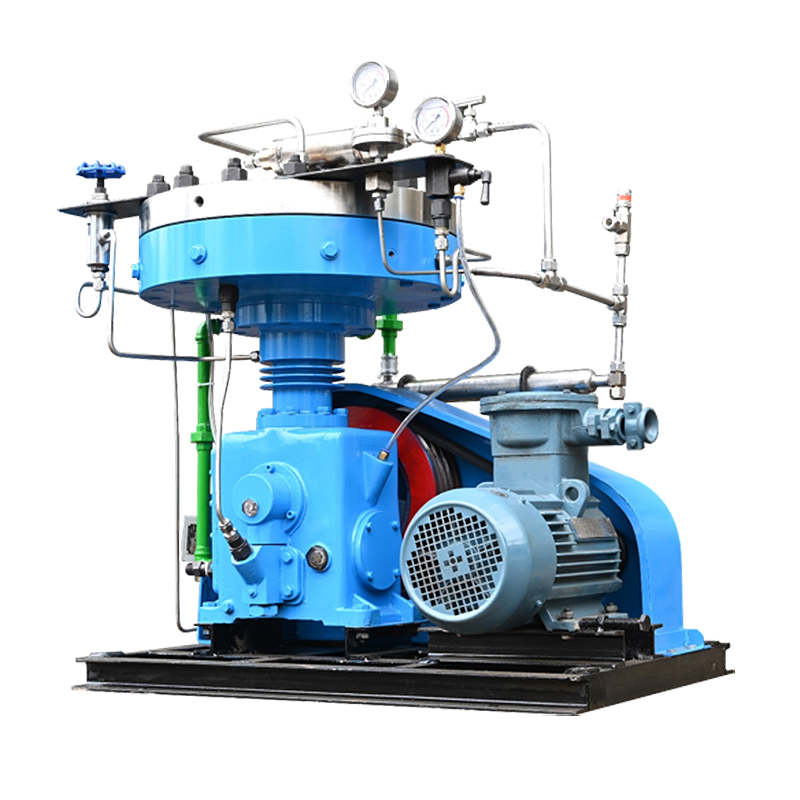

V Type Diaphragm Air Compressor

| Structure type: | V type |

| Piston travel: | 70-130mm |

| Max.piston force: | 10KN-30KN |

| Max.discharge pressure: | 50Mpa |

| Flow-rate range: | 2-100Nm3/h |

| Motor power: | 2.2KW-30KW |

Applicable compression medium: high-purity gas, inert gas, flammable and explosive gas, toxic gas, special gas, inlet pressure and exhaust pressure are gauge pressure

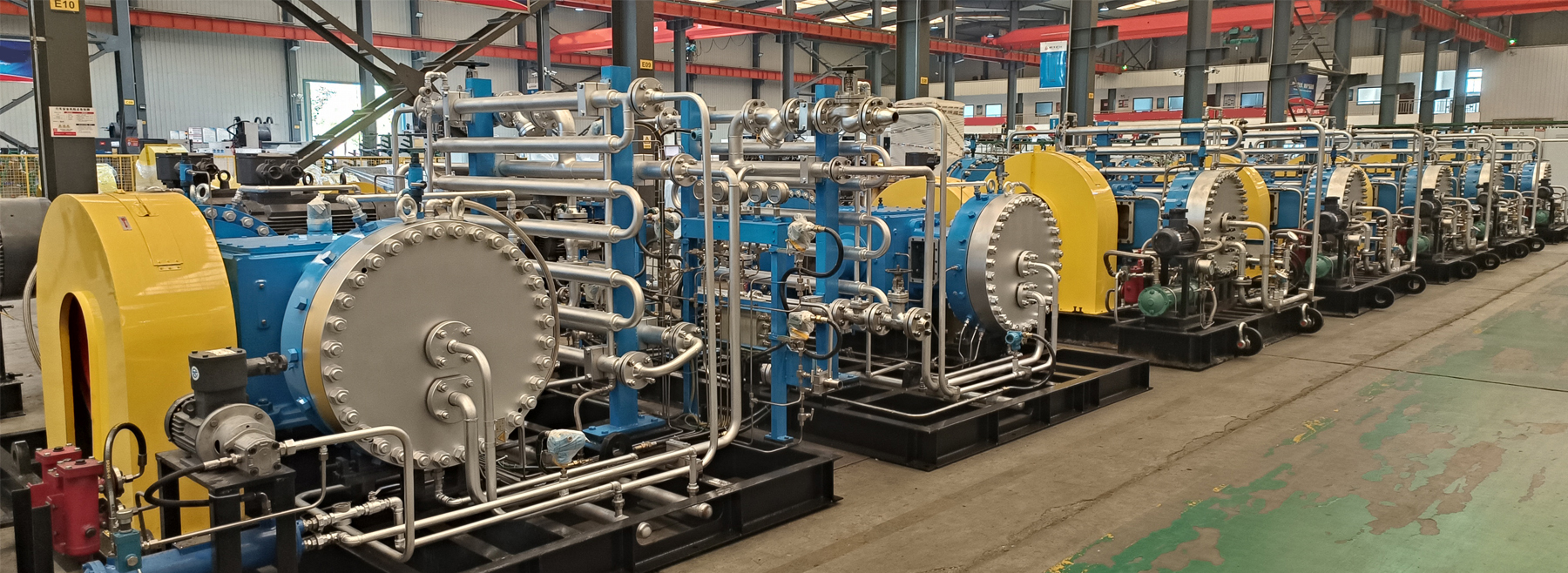

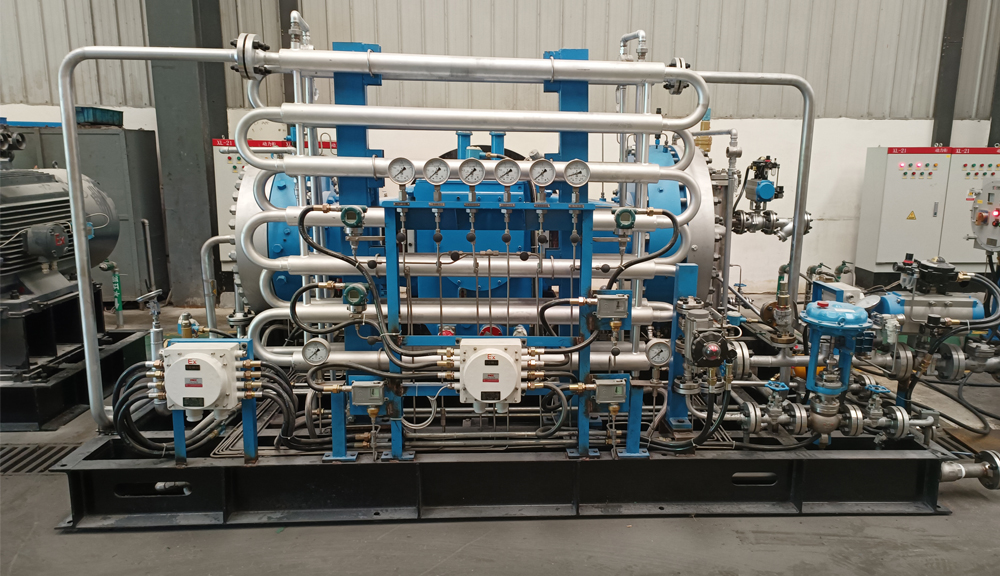

D Type Diaphragm Air Compressor

| Structure type: | D type |

| Piston travel: | 130-210mm |

| Max.piston force: | 40KN-160KN |

| Max.discharge pressure: | 100Mpa |

| Flow-rate range: | 30-2000Nm3/h |

| Motor power: | 22KW-200KW |

Applicable compression medium: high-purity gas, inert gas, flammable and explosive gas, toxic gas, special gas, inlet pressure and exhaust pressure are gauge pressure

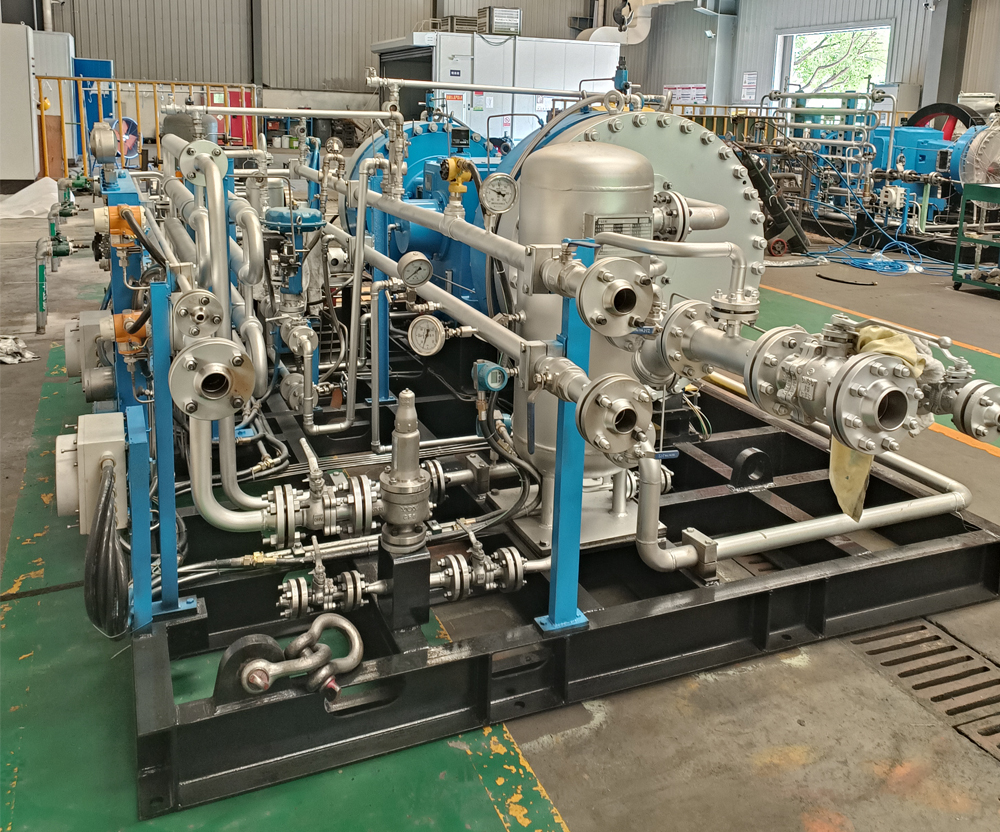

L Type Diaphragm Air Compressor

| Structure type: | L type |

| Piston travel: | 110-180mm |

| Max.piston force: | 20KN-90KN |

| Max.discharge pressure: | 100Mpa |

| Flow-rate range: | 10-1000Nm3/h |

| Motor power: | 7.5KW-90KW |

Applicable compression medium: high-purity gas, inert gas, flammable and explosive gas, toxic gas, special gas, inlet pressure and exhaust pressure are gauge pressure

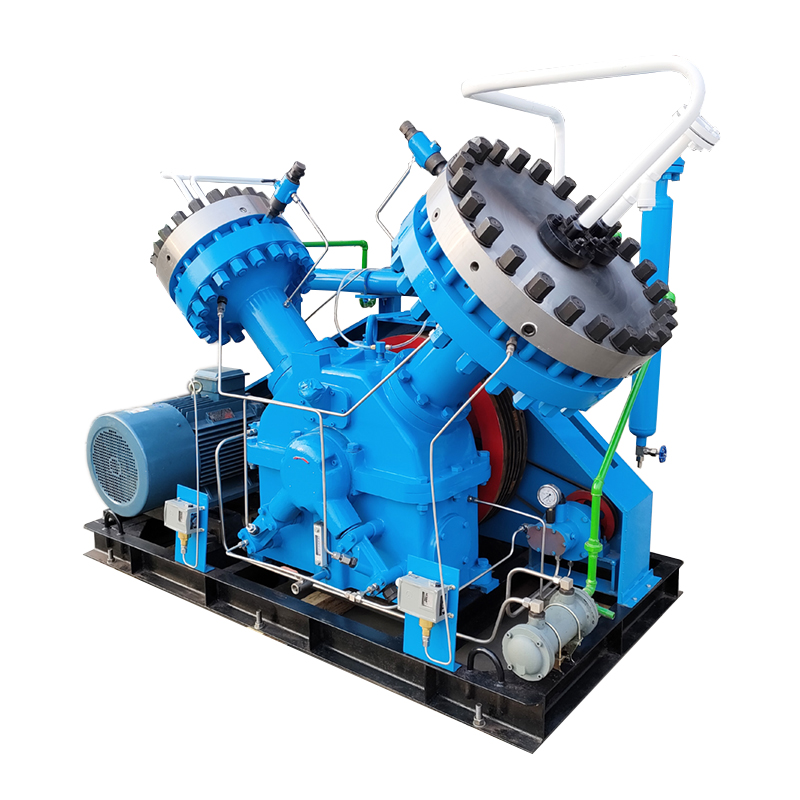

Z Type Diaphragm Air Compressor

| Structure type: | Z type |

| Piston travel: | 70-180mm |

| Max.piston force: | 10KN-90KN |

| Max.discharge pressure: | 70Mpa |

| Flow-rate range: | 0.5-500Nm3/h |

| Motor power: | 2.2KW-45KW |

Applicable compression medium: high-purity gas, inert gas, flammable and explosive gas, toxic gas, special gas, inlet pressure and exhaust pressure are gauge pressure

Why Choose Sollant

Diaphragm Compressor

- The hydrogen gas compressor has a reasonable structure design, stable and reliable operation, low vibration, and low noise.

- The cylinder body parts adopt the structure without a matching plate, which reduces the difficulty of the assembly process and reduces the sealing surface.

- The new-type membrane cavity curve and the imported gas valve improve the volumetric efficiency of the compressor

- The entire diaphragm type compressor is concentrated on a skid-mounted chassis, which is convenient for transportation and installation.

Diaphragm compressor is a reciprocating compressor with a special structure. It has a large compression ratio, good sealing performance, and the compressed gas is not polluted by lubricating oil and other solid impurities. It is suitable for compressing high-purity, rare and precious, flammable and explosive, Toxic, harmful, corrosive and high-pressure gases.

Diaphragm compressors designed and manufactured by “Sollant” are divided into four categories of V, Z, D and L, 26 series, and nearly 900 products. The maximum displacement of a single unit of the product is 3000Nm3/h, the maximum pressure design range is 100MPa, the maximum piston force is 250KN, and the maximum driving power is 450KW.

Market:

Energy and Fuel Cells

Petrochemical

Silicon manufacturing

Research and development

Pilot plant

Application:

Hydrogen

Fluorine

Oxidation

Harmful gas

Corrosive gas

Keep us Update on Latest Air Compressor Newsletter

Advancing Hydrogen Technology: Exploring Diaphragm Compressors

Hydrogen technology stands as a beacon of hope in the clean energy sector, offering a promising solution to the global quest for sustainable and eco-friendly energy sources.

As the world grapples with the urgent need to reduce carbon emissions and combat climate change, hydrogen emerges as a versatile and efficient energy carrier with immense potential. This introductory section aims to shed light on the significance of hydrogen technology and its role in revolutionizing the energy landscape.

In recent years, hydrogen has gained substantial attention due to its diverse applications, ranging from transportation and industrial processes to electricity generation. It offers a unique advantage of being a clean fuel, emitting only water vapor when used in fuel cells or combustion processes. Furthermore, its ability to be produced from various renewable sources, including water electrolysis powered by renewable energy, positions hydrogen as a linchpin in achieving a low-carbon future.

One of the pivotal aspects of harnessing hydrogen’s potential lies in its compression, a process that facilitates its storage and transportation. Effective compression ensures that hydrogen can be stored in a compact form, making it feasible for various applications and distribution networks. This article delves into the integral role of hydrogen compression and, more specifically, the groundbreaking advancements in diaphragm compressors that contribute to making hydrogen technology a reality.

Evolution of Hydrogen Technology

Hydrogen, the most abundant element in the universe, has captured the imagination of researchers and innovators as a versatile and clean energy source. Its potential lies not only in its abundance but also in its remarkable ability to release energy when undergoing combustion or reacting in fuel cells, generating power without the emissions that accompany fossil fuels. With growing concerns about climate change and the depletion of traditional energy resources, hydrogen emerges as a beacon of hope in the quest for sustainable energy solutions.

Hydrogen’s potential as a renewable energy source stems from its diverse production methods. One of the most promising methods involves water electrolysis, a process powered by renewable energy sources such as solar and wind power. Electrolysis breaks down water molecules into hydrogen and oxygen, resulting in a clean and emissions-free hydrogen production process. This production method aligns seamlessly with the principles of sustainability and reduces the carbon footprint associated with conventional energy production.

Hydrogen’s versatility goes beyond its role as a fuel source. It plays a pivotal role in energy storage, addressing the intermittent nature of renewable energy sources like solar and wind. Excess energy generated during peak production periods can be converted into hydrogen through electrolysis and stored for later use. When energy demand rises, the stored hydrogen can be efficiently converted back into electricity using fuel cells, providing a reliable and sustainable energy supply.

Fuel cells, another crucial application of hydrogen, exemplify its transformative potential. These electrochemical devices convert hydrogen directly into electricity, with water and heat as the only byproducts. Fuel cells find application in various sectors, from transportation to stationary power generation, offering an efficient and environmentally friendly alternative to traditional combustion-based power systems.

Basics of Diaphragm Compressors

Diaphragm compressors stand as essential components in the intricate process of hydrogen compression, playing a pivotal role in ensuring the efficient and safe transfer of hydrogen gas. As hydrogen is a low-density gas, compressing it to higher pressures is critical for storage, transportation, and utilization in various applications. Diaphragm compressors serve as the linchpin in achieving this compression while maintaining the purity and integrity of the hydrogen gas.

The importance of diaphragm compressors lies in their capability to handle hydrogen gas with precision and reliability. Unlike traditional compression methods, diaphragm compressors utilize a unique mechanism that minimizes the risk of contamination and leakage, crucial factors when dealing with hydrogen’s sensitive nature. By maintaining a hermetic seal between the gas and the drive mechanism, diaphragm compressors ensure that the compressed hydrogen remains free from any external impurities.

Diaphragm compressors operate based on the principle of positive displacement. The heart of a diaphragm compressor is a flexible diaphragm, typically made of metal or high-performance polymers. As the diaphragm reciprocates, it alternately expands and contracts the compression chamber. During the expansion phase, hydrogen gas is drawn into the chamber through an inlet valve. As the diaphragm contracts, the gas volume decreases, leading to its compression. An outlet valve then opens, allowing the compressed hydrogen to exit the chamber.

Key Features and Advantages of Diaphragm Compressors:

- Hermetic Sealing: The diaphragm’s sealing action ensures that hydrogen remains isolated from any lubricants or contaminants present in the drive mechanism.

- Contamination-Free Compression: Diaphragm compressors prevent gas contamination, preserving the purity of the compressed hydrogen, which is crucial for fuel cells and other sensitive applications.

- Versatility: Diaphragm compressors can handle various gases and offer adjustable compression ratios, making them adaptable to different requirements.

- Precise Pressure Control: These compressors provide precise pressure control and are capable of delivering high pressures, essential for efficient hydrogen storage and distribution.

Efficient Energy Conversion: Challenges in Hydrogen Compression

The compression of hydrogen gas to high pressures is a critical step in its utilization across various applications, from industrial processes to fuel cells. However, this process presents several challenges that demand innovative solutions. One significant challenge is hydrogen’s inherent compressibility.

As hydrogen molecules are small and lightweight, they tend to exhibit high levels of compressibility, requiring substantial energy input to achieve the desired pressure levels. This translates to energy losses during compression, reducing overall efficiency.

Moreover, safety concerns associated with hydrogen compression cannot be understated. Hydrogen’s high flammability and potential for embrittlement in certain materials require meticulous handling and equipment design to mitigate risks. Ensuring a secure and leak-free compression process is paramount to prevent accidents and safeguard both operators and the environment.

Diaphragm compressors emerge as a solution that addresses the challenges posed by high-pressure hydrogen compression. Their unique design and operation significantly enhance efficiency and reliability while minimizing safety risks.

Diaphragm compressors’ positive displacement mechanism ensures precise compression, overcoming hydrogen’s compressibility issue. The diaphragm’s hermetic sealing capability prevents contamination and leakage, a crucial aspect in maintaining the purity of the compressed hydrogen.

The use of diaphragm compressors in hydrogen compression also aligns well with safety requirements. Their design reduces the likelihood of gas leaks and minimizes the risk of hydrogen embrittlement in compressor components. As a result, diaphragm compressors provide a safer environment for operators and the surrounding ecosystem.

Applications of Diaphragm Compressors in Hydrogen Technology

Diaphragm compressors play a pivotal role in various facets of hydrogen technology, powering critical applications that drive the clean energy revolution. One such application is hydrogen storage.

Compressed hydrogen is a versatile means of storing excess energy from renewable sources, providing a reliable backup for times of low energy generation. Diaphragm compressors contribute by efficiently compressing hydrogen for storage in tanks, ensuring that energy can be stored and released when needed.

Another application lies in hydrogen transportation. Compressed hydrogen can be transported over long distances to reach areas where it’s needed for various industrial processes, power generation, or fueling stations. Diaphragm compressors facilitate safe and efficient compression of hydrogen for transportation, supporting the growth of a hydrogen economy.

Perhaps one of the most transformative applications is in fuel cells. Fuel cells utilize hydrogen and oxygen to generate electricity through an electrochemical process, with water as the only byproduct. Diaphragm compressors ensure the delivery of high-purity compressed hydrogen to fuel cells, enabling efficient power generation with minimal environmental impact. Their ability to maintain gas purity is crucial for fuel cell performance and longevity.

The integration of diaphragm compressors into various hydrogen applications is a key driver in advancing the commercialization of hydrogen technology. These compressors enhance the overall efficiency, reliability, and safety of hydrogen-related processes, making them more viable for widespread adoption.

As hydrogen gains traction as a clean energy carrier, diaphragm compressors provide the foundation for a seamless transition to hydrogen-based solutions.

Diaphragm compressors contribute to creating a robust and interconnected hydrogen infrastructure, enabling industries to utilize hydrogen with confidence. The application of these compressors not only accelerates technological innovation but also accelerates the growth of the hydrogen economy, offering sustainable energy alternatives to traditional fossil fuels.

Technological Innovation and Sustainable Development

In the dynamic landscape of hydrogen technology, diaphragm compressor manufacturers have risen to the occasion by spearheading innovative solutions to meet the evolving demands of the industry. These manufacturers recognize the pivotal role that diaphragm compressors play in advancing hydrogen applications and have embarked on a journey of continuous technological innovation.

Diaphragm compressor manufacturers are committed to enhancing the efficiency, performance, and safety of their products. This includes refining the design and materials used in diaphragms, valves, and seals to optimize compression processes. Additionally, manufacturers are integrating advanced automation and control systems to ensure precise pressure control, making hydrogen compression more adaptive and responsive to varying demands.

Diaphragm compressor manufacturers are not only driving technological innovation but also actively contributing to sustainable development goals. One significant aspect of this contribution is their dedication to reducing the carbon footprint associated with hydrogen production and utilization.

By designing energy-efficient compressors and leveraging renewable energy sources in their manufacturing processes, these manufacturers align their operations with the principles of environmental stewardship.

Furthermore, the advancements made by diaphragm compressor manufacturers directly impact the wider adoption of hydrogen technology. As hydrogen gains prominence as a clean energy solution, diaphragm compressors enable industries to transition away from fossil fuels, leading to reduced greenhouse gas emissions and improved air quality. By facilitating the efficient compression of hydrogen, these manufacturers play a crucial role in accelerating the global shift towards sustainable energy practices.

Case Study Showcase

In the bustling city of New Energyville, a groundbreaking hydrogen refueling station project emerged as a testament to the transformative potential of diaphragm compressors in advancing hydrogen technology. Facing the challenge of transitioning to cleaner transportation solutions, the city embarked on a journey to establish a comprehensive hydrogen infrastructure to power fuel cell vehicles.

Central to the success of this project was the integration of diaphragm compressors in the hydrogen refueling station. These compressors were strategically positioned to efficiently compress hydrogen gas, ensuring a steady and reliable supply of high-purity compressed hydrogen to fuel cell vehicles.

The diaphragm compressors played a crucial role in overcoming challenges associated with hydrogen compression, enabling seamless and safe refueling operations.

The implementation of diaphragm compressors in the hydrogen refueling station project resulted in significant advancements in hydrogen technology. The station provided a practical and convenient refueling solution for fuel cell vehicles, fostering their adoption and promoting sustainable transportation alternatives. Diaphragm compressors contributed to the efficient operation of the station, reducing refueling time and enhancing the overall user experience.

The successful deployment of diaphragm compressors in the hydrogen refueling station had far-reaching implications. It demonstrated the feasibility of hydrogen infrastructure and showcased the pivotal role of diaphragm compressors in making hydrogen technology commercially viable.

As more fuel cell vehicles accessed the refueling station, the city’s efforts aligned with global sustainability goals by reducing emissions and promoting cleaner transportation.

This case study serves as a prime example of how diaphragm compressors can drive the advancement and commercialization of hydrogen technology. By addressing challenges, enhancing efficiency, and enabling practical applications, diaphragm compressors contribute to the realization of a hydrogen-powered future.

As the world continues to prioritize sustainable energy solutions, this case study highlights the transformative impact of innovative technologies on shaping a cleaner and more sustainable energy landscape.

Future Prospects

The future of hydrogen technology holds immense promise as the world strives for cleaner, more sustainable energy solutions. Hydrogen’s versatility is expected to drive innovation across diverse sectors, ranging from transportation and industrial processes to power generation. As the demand for hydrogen increases, so does the need for efficient compression solutions.

Diaphragm compressor development is poised to align with these evolving trends, catering to the demands of a burgeoning hydrogen economy. Manufacturers are projected to further enhance the efficiency, adaptability, and safety of diaphragm compressors. Innovations such as smart monitoring systems, enhanced materials, and advanced automation are expected to propel diaphragm compressors into a new era of performance and reliability.

Diaphragm compressors hold a pivotal role in achieving green energy and sustainable development goals, serving as enablers of a clean and emissions-free energy future.

The efficient compression of hydrogen contributes to a reduced carbon footprint by facilitating the utilization of renewable energy sources for hydrogen production. This directly aligns with global efforts to combat climate change and reduce reliance on fossil fuels.

Furthermore, diaphragm compressors play a vital part in fostering the growth of a hydrogen economy. As governments and industries worldwide focus on decarbonization, hydrogen is increasingly recognized as a key player in achieving ambitious sustainability targets.

The efficient and safe compression of hydrogen by diaphragm compressors accelerates its integration into various applications, from powering vehicles to enabling decentralized energy solutions.

As hydrogen technology and diaphragm compressor development converge, they form a dynamic synergy that propels the energy sector towards a greener, more sustainable future.

The innovation and adaptability of diaphragm compressors play an integral role in realizing the potential of hydrogen as a clean energy carrier. By efficiently addressing challenges and enabling practical applications, diaphragm compressors ensure that hydrogen’s promise as a viable and scalable energy solution becomes a reality.

In closing, the harmonious relationship between hydrogen technology and diaphragm compressors highlights the power of collaboration between innovation and sustainable development.

As we navigate the path towards a more environmentally conscious energy landscape, the evolution of diaphragm compressors underscores their enduring significance in driving the transition to a cleaner, more sustainable energy paradigm.

Sollant: A Leading Turkish Specialist in Hydrogen Diaphragm Compressor Manufacturing

In the realm of cutting-edge technology and sustainable energy solutions, Sollant stands as a prominent name, heralding innovative advancements in the field of hydrogen diaphragm compressor manufacturing. As a Turkish-based company with a strong commitment to excellence, Sollant has emerged as a specialist that not only understands the dynamic potential of hydrogen technology but also transforms that potential into reality through their state-of-the-art diaphragm compressors.

Advantages of Sollant’s Products: A Glimpse into Unmatched Excellence

- Technological Precision: At the heart of Sollant’s diaphragm compressors lies a dedication to technological precision. Leveraging advanced engineering techniques, their compressors are meticulously designed to offer efficient and reliable hydrogen compression. The result? Compressors that meet the stringent requirements of the hydrogen industry, ensuring purity, safety, and optimal performance.

- Enhanced Efficiency: Sollant’s commitment to sustainability goes hand in hand with their focus on efficiency. Their diaphragm compressors are engineered to maximize compression efficiency, minimizing energy losses during the compression process. This not only results in lower operational costs but also supports the broader goal of reducing the carbon footprint associated with hydrogen production and utilization.

- Safety as a Priority: Recognizing the unique safety challenges posed by hydrogen, Sollant integrates comprehensive safety features into their diaphragm compressors. These features mitigate the risks associated with hydrogen compression, ensuring operators’ safety and safeguarding the surrounding environment.

- Versatility in Applications: Sollant’s diaphragm compressors are not confined to a single application but cater to a wide range of hydrogen utilization scenarios. From fuel cell systems to industrial processes and energy storage solutions, Sollant’s compressors offer the versatility needed to meet the demands of a rapidly evolving hydrogen economy.

- Innovation-driven: Innovation is the cornerstone of Sollant’s philosophy. Through continuous research and development, they consistently improve their diaphragm compressors to meet the evolving needs of the hydrogen industry. Their commitment to staying ahead of the curve positions them as a driving force in the progression of hydrogen technology.

Sollant’s journey is not merely that of a company; it’s a quest to revolutionize the way we harness and utilize hydrogen’s potential. As the world shifts towards cleaner energy alternatives, Sollant stands at the forefront of innovation, developing diaphragm compressors that serve as the backbone of a sustainable energy future. With technological excellence, efficiency, safety, versatility, and a keen eye on innovation, Sollant is not just a manufacturer – it’s a catalyst for progress in the hydrogen industry.

In a world seeking to reduce its environmental impact and embrace renewable energy, Sollant’s dedication to producing top-tier hydrogen diaphragm compressors places them as a vital contributor to the global efforts towards a greener, more sustainable tomorrow.