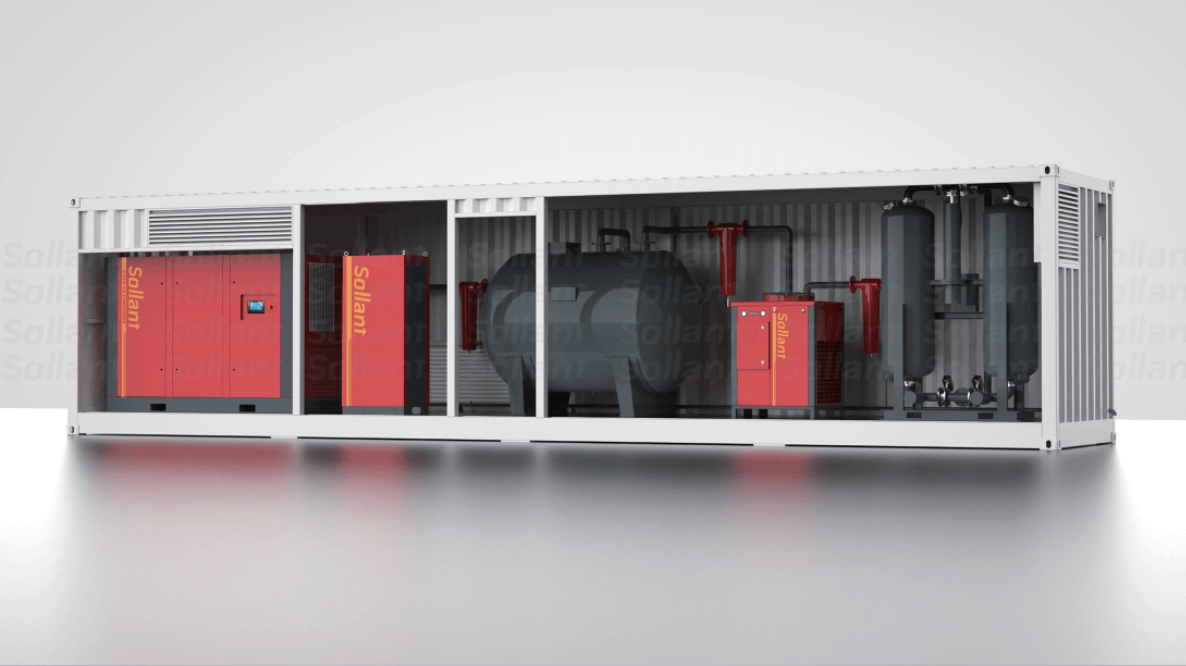

The containerized compressor provides a stable and long-lasting air source.

The container gas supply station is designed for specific industries, as production and workplace environments require constant changes. It features a compact structure, professional configuration, easy lifting and transport, simple installation, and flexible use. It is especially suitable for outdoor work such as field exploration, spraying and sandblasting, municipal engineering, mining and well excavation, marine operations, and construction installations. A single machine offers multiple uses, completely eliminating the tedious work, safety risks, and high costs of temporarily constructing air compressor stations.

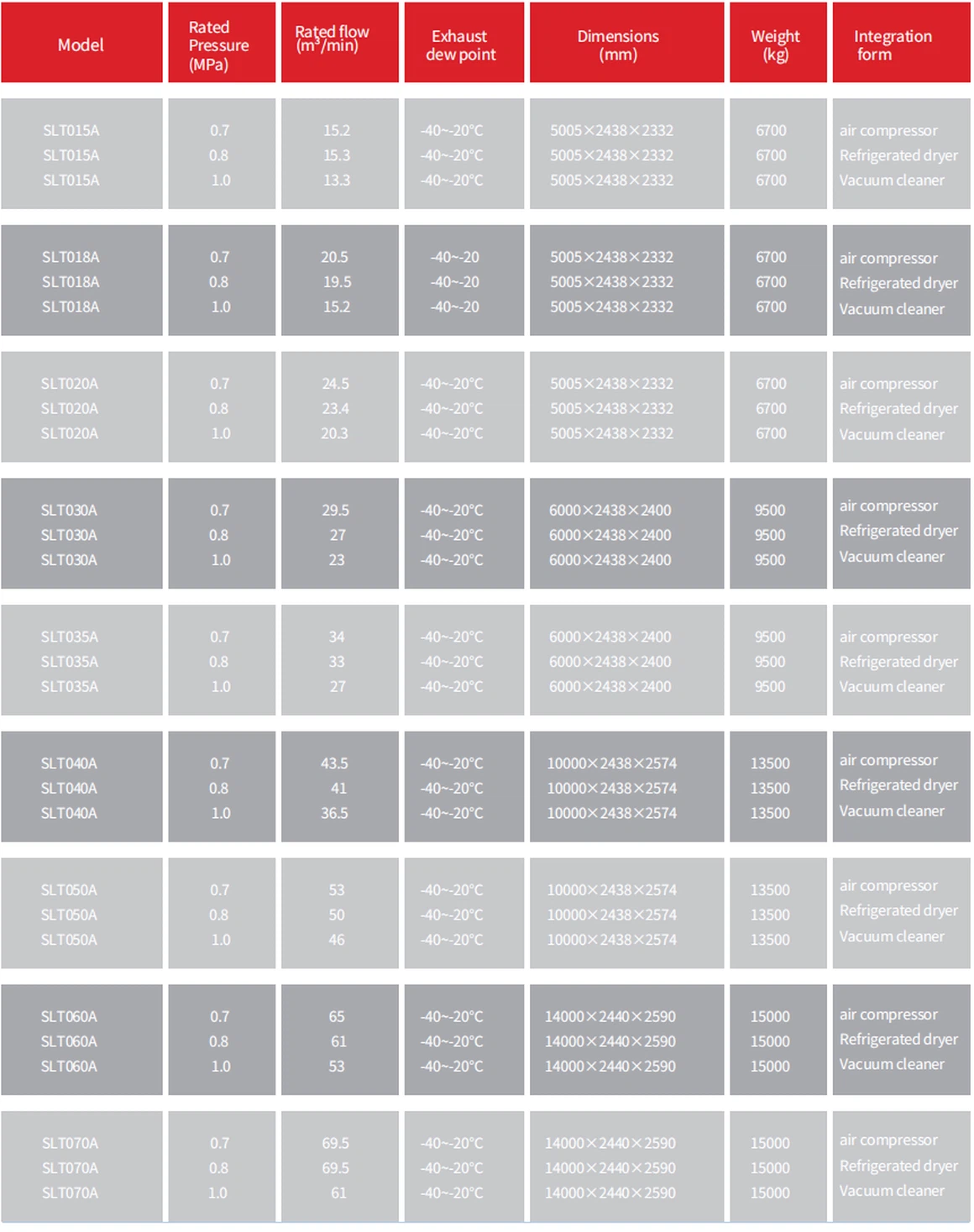

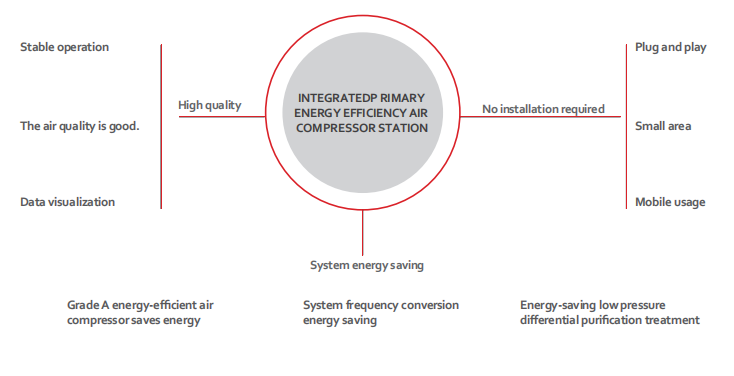

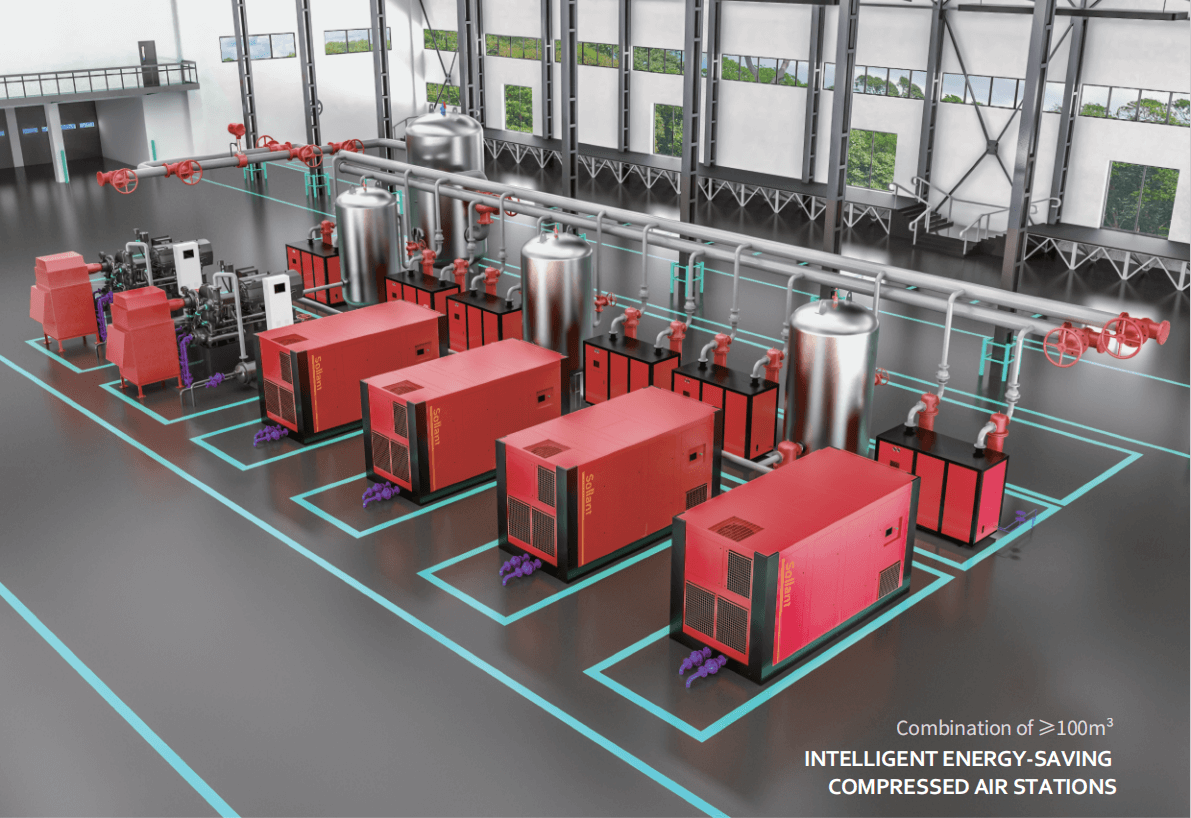

CHARACTERISTICS OF INTEGRATED AIR COMPRESSOR STATIONS

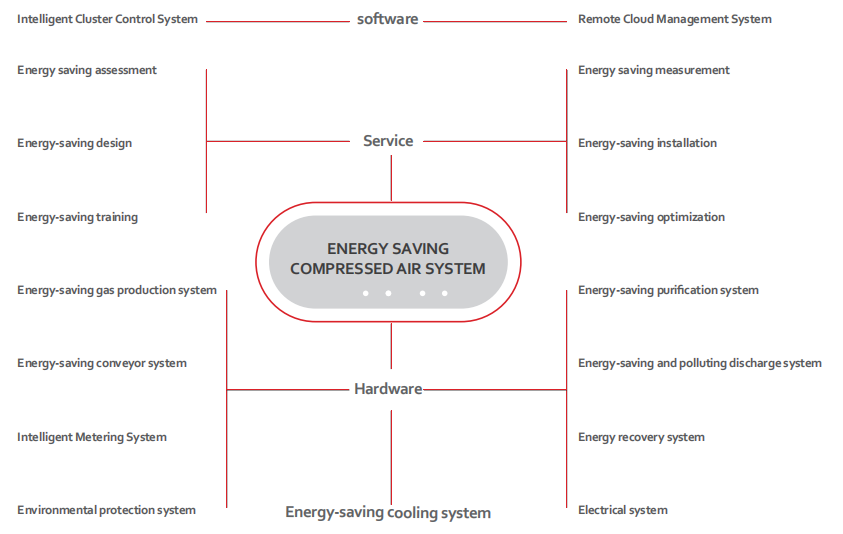

WHY CAN WE?

WHY SAVE ENERGY?

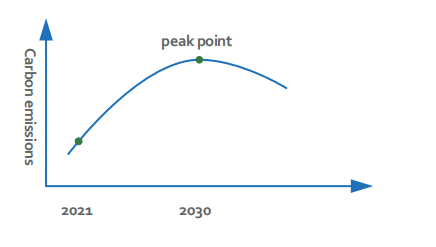

PEAK CARBON DIOXIDE EMISSIONS

At a certain point in time, carbon dioxide emissions will no longer grow and will reach their peak, after which they will gradually decline.

CARBON NEUTRALITY

The state in which the carbon dioxide emissions associated with a certain entity are balanced by the anthropogenic carbon dioxide removal (as defined by the IPCC).

Sollant container screw air compressor manufacturer

Boost your business with containerized screw air compressors

Sollant containerized screw air compressors combine efficient screw compression technology to provide continuous, stable, oil-free, and low-maintenance compressed air solutions.

The containerized design not only improves the equipment's mobility and flexibility, but also simplifies the installation process and is suitable for a variety of working environments.

Why choose Sollant containerized screw air compressors?

- It produces oil-free compressed air, ideal for high-demand industries such as food, pharmaceuticals, and precision manufacturing.

- Screw compressors have fewer friction parts, reducing failure rates and maintenance costs.

- It provides continuous and stable compressed air to ensure continuous and efficient industrial production.

- The container-type structure is easy to transport and quick to set up, adaptable to different work environments, and is especially suitable for temporary construction sites.

Keep us updated on the latest Air Compressor newsletter

Containerized screw air compressor: flexible deployment, stable operation

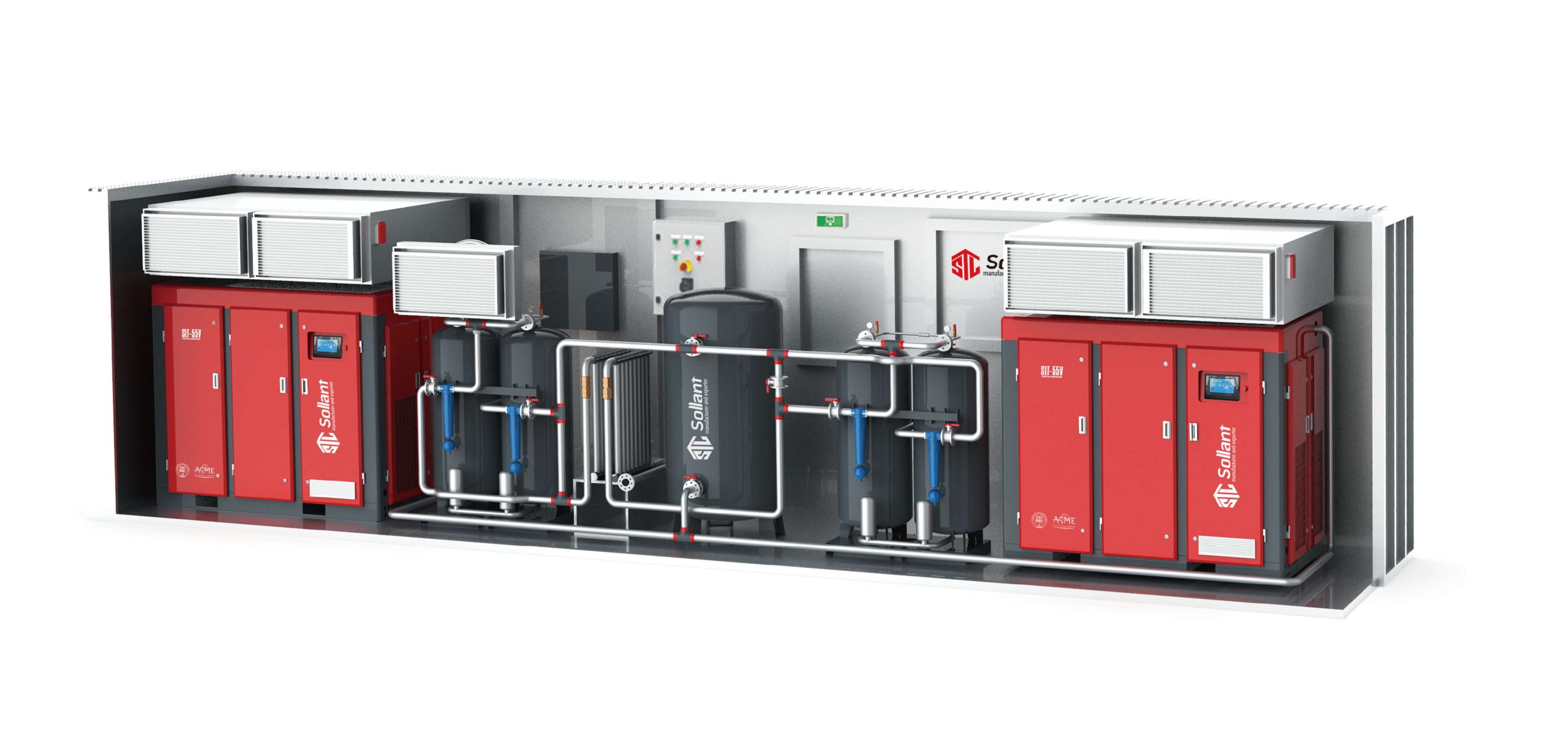

In modern industrial production, compressed air, as an important power source, is widely used in many fields such as machinery manufacturing, mining, energy and electricity, petrochemicals, etc. The traditional fixed air compressor station has a long construction period, occupies a large area, and is unable to cope with the scene where frequent movement or space is limited. As an innovative solution, containerized screw air compressors are gradually changing the industrial gas use mode with their unique advantages. It integrates core equipment such as screw air compressors, gas storage tanks, dryers, precision filters, etc. in a standard container to form a movable, plug-and-play compressed air station. This article will explore the basic overview of containerized screw air compressors, the advantages of flexible deployment, the guarantee of stable operation, the wide range of application areas, how to choose suitable equipment, and finally summarize its outstanding advantages.

Basic Overview of Containerized Screw Air Compressors

Containerized screw air compressors, as the name implies, are an overall solution that encapsulates the screw air compressor system inside a standard container. This design concept aims to provide a highly integrated, modular, easy to transport and deploy compressed air supply unit.

Structural composition

According to the actual needs of users, the air compressor, gas storage tank, dryer, filter, gas distribution tank, waste oil collector, control power cabinet, and other functional equipment are integrated through pipelines, electrical, instrumentation, sewage and ventilation systems and installed in a container.

The inner wall of the box is installed with thermal insulation and noise reduction rock wool materials, and the wall is decorated with porous aluminum plates. LED lighting is installed on the top. The overall interior is luxurious, clean, bright, and heat-insulated and noise-reduced; all ventilation and cooling system inlets and outlets are designed with self-closing shutters and filters to ensure the cooling and ventilation effects of the equipment system, and meet the dust, rain and insect-proof functions; the compressed air outlet and sewage outlet are led out of the box body near the bottom, which is convenient for external connection of the air supply pipeline after the equipment is in place and external sewage discharge after shutdown; the power supply inlet and operation control system are arranged in a small box with a safety door lock outside the box, which is convenient for cable connection and operation control of equipment operation, convenient operation and safety of operators;

The box body is designed with a double-opening door for maintenance and a single-opening door for inspection and collection of tools, and both are equipped with safety door locks to prevent unrelated personnel from entering the box when the equipment is running, which is flexible, convenient and safe; the box structure is equipped with hanging earrings and forklift holes to facilitate hoisting and shoveling operations.

The whole machine is novel, fully functional, dust-proof and rain-proof, sun-proof and anti-freeze, sound-proof and heat-insulated, safe and reliable, easy to maintain, flexible to operate, beautiful and elegant, suitable for use in various environmental climates, and is the preferred equipment for compressed air mobile operations.

Working principle

The working principle of the container-type screw air compressor is basically the same as that of the ordinary screw air compressor. The ambient air enters the screw compressor main unit through the air intake filter, is compressed under the rotation of the screw, and the pressure increases. The compressed high-temperature and high-pressure gas passes through the oil-gas separator to separate the oil and gas. The separated compressed air enters the post-processing equipment, and is cooled by the cooler, dehumidified by the dryer, and filtered by the filter in turn, and finally reaches clean, dry, and compressed air that meets the use requirements. It is stored in the gas storage tank and can be used by gas-using equipment at any time.

Main features

High integration: All equipment is integrated in one box, reducing the workload of on-site installation and wiring.

Convenience of mobility: The standard container design enables it to be transported by road, rail, sea, and other means, which is convenient and quick to deploy to different locations.

Plug and play: Usually, it can be put into operation by simply connecting the power supply and gas pipeline, which greatly shortens the project construction period.

Strong environmental adaptability: The container body has good dust, rain, sun and corrosion resistance, and can operate stably under various harsh climatic conditions.

Low noise and small vibration: After professional sound insulation and noise reduction treatment, the operating noise is much lower than that of an open air compressor station.

Convenient maintenance: Sufficient maintenance space is reserved inside the box to facilitate daily maintenance and troubleshooting of the equipment.

Advantages of flexible deployment

One of the biggest highlights of containerized screw air compressors is its unparalleled flexible deployment capability. This feature enables it to show unparalleled superiority over traditional air compressor stations in many special application scenarios.

One of the biggest highlights of containerized screw air compressors is its unparalleled flexible deployment capability. This feature enables it to show unparalleled superiority over traditional air compressor stations in many special application scenarios.

Quick installation and commissioning

High degree of prefabrication: All equipment, pipelines, cables, etc. are pre-installed and tested in the factory, greatly reducing the installation workload on site. The construction of a traditional air compressor station requires weeks or even months from civil engineering, equipment hoisting, pipeline laying, electrical connection to commissioning. After the containerized air compressor arrives at the site, it can be put into use within hours or days by simply positioning it, connecting the power supply and the air outlet pipe.

Reduce on-site construction: No complex civil engineering foundation is required, usually only a flat ground is required, and it can even be placed directly on a solid platform. This is a huge advantage for rental sites, temporary projects or areas with complex terrain.

Reduce labor costs: The number of people and time required for on-site installation and commissioning is greatly reduced, thereby reducing the labor cost of the project.

Quick response: In the face of sudden gas demand, such as emergency repairs, disaster relief or the establishment of temporary production lines, containerized air compressors can respond quickly and provide compressed air in a timely manner.

Adapt to changing environments

Strong mobility: The standardized design of the container enables it to be transported by a variety of means of transportation, such as flatbed trailers, trains, ships, etc. Whether in remote mines, desert oil fields, offshore platforms, or urban construction sites, it can be easily transferred and deployed.

Adaptability to harsh environments: The container body is sturdy and durable, with dustproof, rainproof, sunproof, anti-corrosion, windproof and other characteristics, and the internal equipment has also been treated with vibration prevention. This enables containerized air compressors to adapt to various harsh outdoor working environments such as plateaus, high temperatures, high cold, dusty, and humid, ensuring the stable operation of the equipment.

High space utilization: In a limited site space, containerized air compressors can achieve efficient equipment integration without the need to build additional factories, saving precious land resources. For example, in construction projects in the city center, where the site is small, containerized air compressors are undoubtedly an ideal choice.

Reduce project costs and risks

Reduce initial investment: Compared with building an independent air compressor station, containerized air compressors do not require large-scale civil engineering projects, significantly reducing initial fixed asset investment.

Convenience of leasing and transfer: Its mobility allows the equipment to be easily transferred between different projects, improving the utilization rate of the equipment, and is particularly suitable for leasing business. For enterprises, they can flexibly adjust equipment configuration according to changes in production needs to avoid idle fixed assets.

Asset flexibility: After the project is completed, the containerized air compressor can be easily disassembled and transferred to the next project, avoiding the sunk cost of fixed assets and improving the liquidity of assets.

Controllable risks: Since most of the equipment is pre-installed and tested in the factory, there are fewer on-site installation links, which greatly reduces the quality and safety risks that may be caused by on-site construction.

Easy to upgrade and expand: If the gas consumption needs to be increased in the future, one or more container modules can be easily added to achieve rapid expansion of the system.

Temporary and emergency gas demand

Emergency standby: When the existing air compressor station fails or is overhauled, the containerized air compressor can be used as a fast-response backup gas source to ensure that production is not affected.

Temporary projects: For short-term projects, temporary production lines, field exploration, large-scale activities and other projects that require temporary gas supply, containerized air compressors are an ideal choice and can be evacuated directly after the project is completed.

Rental market: Many rental companies purchase containerized air compressors to meet customers’ diverse short-term or long-term gas needs and provide flexible solutions for enterprises.

Guarantee of stable operation

Although containerized screw air compressors emphasize flexible deployment, their stable operation capability is also a key factor in measuring their value. Manufacturers have taken a series of measures in the design and production process to ensure that the equipment can operate reliably and efficiently under various conditions.

Although containerized screw air compressors emphasize flexible deployment, their stable operation capability is also a key factor in measuring their value. Manufacturers have taken a series of measures in the design and production process to ensure that the equipment can operate reliably and efficiently under various conditions.

Selection and integration of high-quality equipment

Optimal selection of core components: Use key components such as screw main engine, motor, cooler, valve, electrical components from well-known brands, which have been verified by the market and have excellent performance and reliability. For example, the efficient screw rotor design ensures high efficiency and low energy consumption; high-quality motors provide stable power output.

Professional system integration: The entire compressed air system is designed and integrated by professional engineers. They will reasonably configure each component according to factors such as gas volume demand, pressure requirements, and environmental conditions to ensure high system matching and optimal operating efficiency. The layout of pipelines, valves, and lines has been optimized to reduce pressure loss and failure points.

Strict factory test: Each container air compressor will undergo strict performance test, pressure test, electrical test, noise test, etc. before leaving the factory to ensure that all parameters meet the design requirements and meet the standards for stable operation.

Perfect internal environment control

Efficient ventilation and heat dissipation system: The operation of the compressor will generate a lot of heat. If the heat cannot be dissipated in time, it will cause the equipment to overheat, affecting efficiency and life. The interior of the container is designed with professional air inlets, exhaust vents and high-power cooling fans to form efficient air convection and ensure that the internal temperature is maintained within a suitable range. Some high-end models are also equipped with an intelligent temperature control system to automatically adjust the fan speed according to the internal temperature.

Dust-proof and moisture-proof design: The container body has good sealing, which effectively prevents dust, rain and moisture from entering the box, protecting precision equipment from pollution and corrosion. The air inlet is usually equipped with a high-efficiency air filter to further filter the air entering the box.

Sound insulation and noise reduction treatment: The noise of compressor operation is a common problem in industrial production. The interior of the container is usually covered with multiple layers of sound insulation materials (such as sound insulation cotton and perforated sound-absorbing panels) for all-round coverage, and the air inlet and outlet are silenced to minimize noise pollution and provide a quieter working environment.

Intelligent control and safety protection

PLC intelligent control system: Integrates advanced PLC (programmable logic controller) control system to realize automatic monitoring and management of compressor operation. The system can display operating parameters (pressure, temperature, current, operating time, etc.), fault alarm, historical data recording and other functions in real time.

Multiple safety protection: It has complete safety protection functions, including:

Overload protection: When the motor current exceeds the set value, it will automatically shut down.

Overtemperature protection: When the exhaust temperature, oil temperature, etc. exceed the set value, it will automatically shut down.

Overpressure protection: When the system pressure exceeds the set value, the safety valve will release pressure or automatically shut down.

Reverse phase protection: Prevent the motor from rotating in the opposite direction.

Phase loss protection: Prevent the power supply from running in phase loss and damaging the motor.

Emergency stop button: In an emergency, the power supply can be quickly cut off to stop the equipment.

Remote monitoring and diagnosis (optional): Some high-end container air compressors support remote monitoring. Through the Internet of Things technology, users can view the operating status of the equipment in real time in the office or anywhere, receive alarm information, and even perform remote diagnosis and troubleshooting, which greatly improves the efficiency of operation and maintenance.

Easy maintenance and repair

Humanized design: The internal space layout of the box is reasonable, and sufficient maintenance channels and operating space are reserved, which is convenient for technicians to carry out daily inspections, maintenance (such as replacing filter elements and oil products) and troubleshooting.

Modular design: Some parts adopt modular design, which is convenient and quick to replace, shortening the maintenance time.

Maintenance reminder: The intelligent control system can automatically prompt users to perform regular maintenance according to the operating time or operating status to ensure that the equipment is always in the best working condition.

Application fields of container screw air compressors

Container screw air compressors have found wide applications in many industries and scenarios due to their unique advantages.

Mining and geological exploration

Feature matching: Mines and exploration sites are often located in remote areas with harsh environments, and gas points are scattered and not fixed. Containerized air compressors can be quickly deployed near the working surface to provide stable wind pressure to meet the needs of drilling rigs, rock drills, pneumatic picks, pneumatic tools, ventilation and dust reduction.

Application cases: blast hole drilling in open-pit mines, excavation and support of underground mines, sampling drilling in geological exploration, etc. Its mobility enables the equipment to be flexibly transferred as the working surface advances.

Oil and gas field

Feature matching: The mining sites of oil fields and gas fields are often located in remote areas, and the equipment has high requirements for explosion-proof, corrosion-proof, and earthquake-resistant. Containerized air compressors can be integrated with explosion-proof electrical equipment to adapt to harsh working environments.

Application cases: drilling platforms, oil and gas pipeline construction and maintenance, oil field gas injection and production increase, instrument gas and process gas for refining and chemical units, etc. Its rapid deployment capability is particularly important for offshore drilling platforms or temporary work sites.

Energy and power industry

Feature matching: Power construction (such as thermal power stations, hydropower stations, and wind farms) has a long cycle and is usually outdoors. During the construction of power stations, a large amount of compressed air is required for construction and equipment commissioning.

Application cases: pneumatic tools, sandblasting and rust removal, pipeline purging, and instrumentation at power construction sites; providing backup gas sources during power plant maintenance; installation and maintenance of wind turbines at wind farms.

Construction Engineering and Infrastructure Construction

Feature Matching: Construction sites have a large demand for gas and the gas use points are variable, and engineering projects are temporary. Containerized air compressors can be easily moved with the progress of the project.

Application cases: pneumatic tools (such as concrete vibrators, pneumatic picks), spraying equipment, template cleaning, pneumatic transportation, etc. in tunnel excavation, bridge construction, road construction, and high-rise building construction.

Shipbuilding and Port Terminals

Feature Matching: Shipbuilding plants and port terminals have a large demand for compressed air, and some operations are carried out outdoors or on the move.

Application cases: sandblasting and rust removal, hull painting, pneumatic welding, and pneumatic tools in shipbuilding; ship berthing assistance at port terminals, pneumatic equipment in container yards, etc.

Temporary production and emergency rescue

Feature matching: In response to emergencies, disaster relief, temporary production lines or large-scale activities, fast and reliable compressed air supply is required.

Application cases: Air supply for rescue equipment at disaster sites such as earthquakes and floods; Air supply for equipment in temporary medical stations and field kitchens; Temporary air sources for large concerts and exhibitions; Backup air sources during temporary production lines or equipment maintenance of enterprises.

Military and special fields

Feature matching: Military equipment has extremely high requirements for reliability, environmental adaptability, and rapid deployment capabilities.

Application cases: Field maintenance, military exercises, air supply for pneumatic systems of special vehicles, etc.

Rental industry

Feature matching: Rental companies need to provide a variety of equipment to meet customers’ short-term or long-term gas needs. The mobility and plug-and-play characteristics of containerized air compressors make them a popular product in the rental market.

Choose a suitable containerized screw air compressor

To choose a containerized screw air compressor that suits your needs, you need to consider multiple factors to ensure maximum investment benefits and optimal operating efficiency.

Clarify the gas demand

This is the first step in selecting an air compressor. You need to understand the following parameters in detail:

Required gas volume (exhaust volume): The unit is usually m³/min or cfm. It is necessary to calculate the theoretical gas consumption of all gas-using equipment, and consider the possibility of future expansion, leaving a certain margin (usually it is recommended to reserve 10%-20% growth space).

Required pressure: The unit is usually bar or psi. It is necessary to understand the minimum working pressure required by the gas-using equipment. The rated exhaust pressure of the air compressor should be slightly higher than the minimum working pressure of the highest gas-using equipment to compensate for the pipeline pressure loss.

Gas quality: Are there any special requirements for the cleanliness and dryness of compressed air? For example, the spraying, medical, and food industries have strict restrictions on the oil, water, and dust content in the air. This determines whether it is necessary to configure high-quality post-processing equipment such as cold dryers, adsorption dryers, and precision filters.

Evaluate the working environment

Although containerized air compressors have strong environmental adaptability, they still need to be selected according to the specific working environment:

Ambient temperature: In high or low temperature environments, it is necessary to select lubricating oil and cooling systems with special temperature resistance, and consider whether additional heating or cooling devices are needed.

Altitude: The air is thin in high altitude areas, which will affect the gas output and efficiency of the compressor. It is necessary to select models that have been designed for plateau adaptability.

Dust/humidity: If the working environment is dusty or humid, it is necessary to select models with higher protection levels and more complete filtration systems, and consider anti-corrosion treatment.

Noise requirements: If there are strict restrictions on noise, it is necessary to select models with higher levels of sound insulation and noise reduction measures.

Power supply conditions: Confirm whether the on-site power supply voltage, frequency, and number of phases match the air compressor, and whether the power supply capacity is sufficient.

Consider brand and quality

Brand reputation: Choose well-known brands with good reputation and mature technology in the market. They are usually more guaranteed in product design, manufacturing process, quality control and after-sales service.

Core components: Understand the brand and quality of the core components such as the screw main engine, motor, cooler, control system, etc. used in the air compressor, which directly affects the performance and life of the equipment.

Container body quality: Check the steel quality, welding process, anti-corrosion treatment, sealing, internal layout and structural strength of the container to ensure that it can withstand the test of long-term transportation and outdoor environment.

Pay attention to energy efficiency ratio and operating cost

Energy efficiency level: Choose an air compressor with a high energy efficiency level (such as national first-level energy efficiency). Although the initial investment may be slightly higher, long-term operation can significantly save electricity bills and reduce the total cost of ownership.

Frequency conversion technology: If the gas consumption fluctuates greatly, you can consider choosing a variable frequency screw air compressor. Frequency conversion technology can adjust the motor speed in real time according to the gas consumption, avoid no-load loss, and further save energy.

Maintenance cost: Understand the daily maintenance cycle of the equipment, the replacement cost and availability of wearing parts. Choose a model with easy maintenance and sufficient supply of accessories.

After-sales service and technical support

Service network: Understand whether the supplier’s after-sales service network is complete and whether it can provide timely and professional installation guidance, technical training, fault diagnosis and maintenance services.

Spare parts supply: Ensure timely supply of spare parts to avoid long-term equipment downtime due to lack of accessories.

Warranty period: Understand the warranty period and warranty scope of the equipment.

Special functions and customized requirements

Remote monitoring: If you need to remotely manage and diagnose the equipment, you can choose a model that supports the IoT remote monitoring function.

Explosion-proof requirements: In specific industries such as petroleum and chemical industry, container-type air compressors with explosion-proof grades may be required.

Special coating: Depending on environmental requirements, special anti-corrosion coatings or colors may be required.

Scalability: Consider whether it is convenient to expand the equipment when the gas consumption increases in the future.

Conclusion

Container-type screw air compressors have shown strong vitality in the modern industrial field with their core advantages of “flexible deployment and stable operation”. It is not only a powerful supplement to traditional air compressor stations, but also an ideal solution for many special working conditions. From mines and oil fields to construction sites, from emergency rescue to temporary production, containerized air compressors provide efficient and reliable compressed air supply for all walks of life with their high integration, rapid response, strong environmental adaptability and high cost-effectiveness.

With the continuous advancement of industrialization and the increasing requirements for production efficiency, environmental protection and cost control, the market demand for containerized screw air compressors will continue to grow. In the future, with the deep integration of technologies such as the Internet of Things, big data and artificial intelligence, containerized air compressors will surely develop in a smarter, more efficient and more environmentally friendly direction, contributing more to global industrial development. Choosing a high-quality containerized screw air compressor will be an important strategic choice for enterprises to improve production efficiency, reduce operating costs and enhance market competitiveness.