Screw air compressors are crucial in various industrial applications, providing a reliable source of compressed air. They are designed to compress air using two interlocking rotors, which trap and compress the air as it passes through the unit. There are two primary types of screw compressors: single-stage and two-stage. Both are commonly used in a variety of industries, but they differ in performance, efficiency, pressure output, and application suitability. This article will explore the key differences between these two types of compressors, comparing them in terms of operation, efficiency, capacity, maintenance, and cost.

Screw air compressors are crucial in various industrial applications, providing a reliable source of compressed air. They are designed to compress air using two interlocking rotors, which trap and compress the air as it passes through the unit. There are two primary types of screw compressors: single-stage and two-stage. Both are commonly used in a variety of industries, but they differ in performance, efficiency, pressure output, and application suitability. This article will explore the key differences between these two types of compressors, comparing them in terms of operation, efficiency, capacity, maintenance, and cost.

1. Basic Principles of Operation

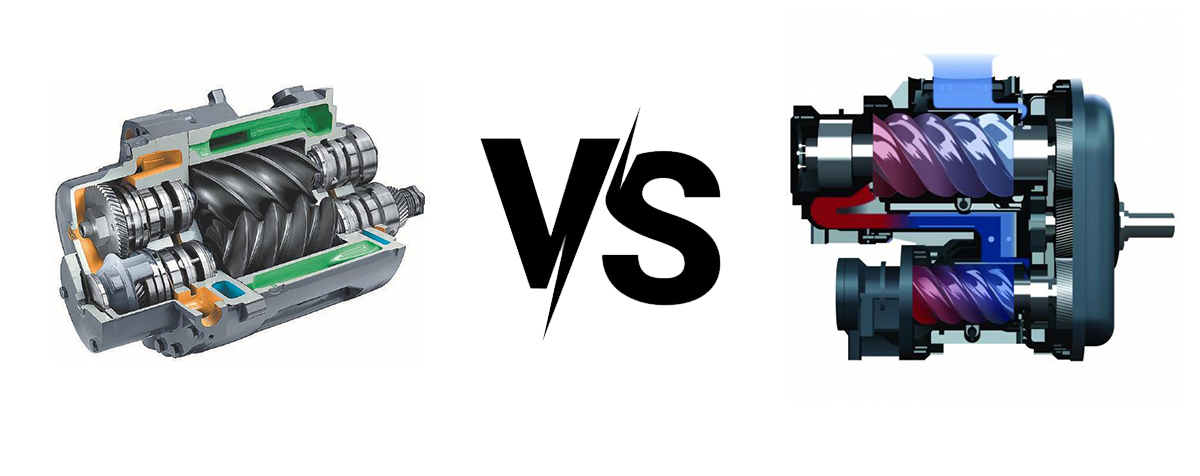

- Single-Stage Screw Compressor:

A single-stage screw compressor operates by compressing the air in one stage. As the air enters the compressor, it is trapped between two helical rotors. These rotors then squeeze the air, gradually reducing its volume as it moves through the compressor. The compression process happens in a single cycle, which makes this type of compressor simpler and more compact.Key Characteristics:- Simple design and fewer components.

- Single compression cycle for air.

- Typically used for applications with lower pressure requirements.

- Two-Stage Screw Compressor:

A two-stage screw compressor takes the air through two separate compression stages. In the first stage, the air is compressed by the first rotor set. After the initial compression, the air is cooled before entering the second compression stage, where it is compressed to a higher pressure. This additional cooling phase helps reduce the temperature of the compressed air, improving efficiency and reducing the risk of overheating.Key Characteristics:- Two compression stages, typically with an intermediate cooling step.

- More complex design and greater capacity.

- Ideal for higher pressure applications.

2. Efficiency and Energy Consumption

- Single-Stage Compressor Efficiency:

Single-stage compressors are less energy-efficient compared to two-stage compressors, especially when working in environments that require high pressure. Since they operate in a single compression cycle, they tend to generate more heat, which can increase energy consumption. Additionally, single-stage compressors may be less efficient when there are variations in air demand.Energy Efficiency:- Typically suited for low- to moderate-pressure applications.

- Higher energy consumption at higher loads or pressures.

- Less energy-efficient when dealing with fluctuations in demand.

- Two-Stage Compressor Efficiency:

Two-stage compressors are generally more energy-efficient. The dual compression stages allow the air to be cooled between stages, which helps reduce the overall energy required to achieve the desired pressure. This cooling phase reduces the risk of overheating, and the compressor operates more efficiently over a wider range of conditions. The two-stage process also minimizes the amount of work required by each stage, improving energy savings.Energy Efficiency:- More energy-efficient, especially at higher pressures.

- Ideal for variable-load applications.

- More efficient in delivering higher pressures with less energy consumption.

3. Compression Capacity and Pressure Output

- Single-Stage Compressor:

Single-stage compressors are designed to handle moderate pressure levels, typically up to 150-200 psi. These compressors work well for applications where high pressure is not critical, such as in small to medium-sized industrial operations. While they can handle continuous air demands, they are limited in their ability to generate higher pressures.Pressure Output:- Best for applications requiring pressures up to 150-200 psi.

- Limited capacity for higher pressure needs.

- Two-Stage Compressor:

Two-stage compressors, on the other hand, can achieve much higher pressures—typically up to 300 psi or more. The additional compression stage and the cooling step between stages allow these compressors to produce higher pressure outputs while maintaining efficiency. This makes them ideal for industries requiring constant, high-pressure air.Pressure Output:- Can handle pressures of up to 300 psi or more.

- Suitable for high-pressure applications in industries like manufacturing, mining, and oil and gas.

4. Maintenance and Longevity

- Single-Stage Compressor Maintenance:

Due to their simpler design, single-stage compressors are easier to maintain. They have fewer moving parts, and the absence of a second compression stage reduces the potential for wear and tear. Maintenance tends to be less frequent and less costly. The overall lifespan of a single-stage compressor is often longer if it is properly maintained.Maintenance Considerations:- Simple design with fewer components to maintain.

- Lower maintenance costs and intervals.

- Easier and quicker to service.

- Two-Stage Compressor Maintenance:

Two-stage compressors have a more complex design, which can lead to higher maintenance requirements. The additional compression stage, cooling system, and extra components mean that maintenance checks need to be more frequent. Parts such as the cooling system and intermediate cooler require regular inspection and servicing. While maintenance costs can be higher, the longer service intervals and durability often justify the investment.Maintenance Considerations:- More complex system requires more frequent maintenance.

- Higher maintenance costs, especially for cooling systems and internal components.

- Longer service intervals between major overhauls.

5. Cost of Installation and Operation

- Single-Stage Compressor Costs:

Single-stage compressors generally have a lower initial purchase cost due to their simpler design and fewer components. The lower upfront cost makes them an attractive choice for smaller operations or businesses with moderate air demands. However, they may have higher operational costs over time if used for applications requiring high pressure or continuous operation.Costs:- Lower initial purchase cost.

- Less expensive to install and operate in low-pressure applications.

- Potentially higher operating costs at higher pressures.

- Two-Stage Compressor Costs:

Two-stage compressors have a higher initial cost due to their more complex design and advanced components. However, their greater efficiency in energy consumption and ability to handle high-pressure applications often result in lower operating costs in the long run. They are a good investment for larger operations or industries requiring consistent high pressure.Costs:- Higher initial purchase cost.

- More expensive to install and maintain.

- Potential for greater long-term savings due to energy efficiency and higher pressure capabilities.

6. Applications and Suitability

- Single-Stage Compressor Applications:

Single-stage compressors are ideal for applications with low to medium air pressure demands. Common industries that use single-stage compressors include automotive repair shops, small manufacturing facilities, construction sites, and light industrial applications. These compressors are perfect for tasks like powering tools, inflating tires, or operating small pneumatic systems.Applications:- Automotive workshops.

- Small to medium-sized manufacturing operations.

- Light industrial processes and construction.

- Two-Stage Compressor Applications:

Two-stage compressors are designed for more demanding industrial applications requiring high-pressure, continuous air supply. They are commonly used in heavy industries like mining, oil and gas, manufacturing, and large-scale operations where reliability and higher pressure are essential. Applications include powering industrial machinery, operating pneumatic systems in large factories, and providing compressed air in energy production.Applications:- Heavy industrial applications (oil, gas, manufacturing).

- Mining, large-scale construction, and petrochemical industries.

- Applications requiring sustained high-pressure air supply.

7. Noise and Vibration

- Single-Stage Compressor Noise and Vibration:

Due to the simpler design, single-stage compressors tend to produce less noise and vibration. The fewer moving parts and lack of a secondary compression stage mean there is less mechanical strain, resulting in quieter operation. For environments where noise is a concern, this can be a significant advantage.Noise Considerations:- Lower noise levels and vibrations.

- Ideal for noise-sensitive environments.

- Two-Stage Compressor Noise and Vibration:

Two-stage compressors tend to be noisier due to their more complex operation and additional compression stages. While they are designed to handle high-pressure air, the increased mechanical movements can result in higher noise levels and vibration. Noise reduction methods, such as soundproof enclosures or vibration isolation mounts, may be required in some applications.Noise Considerations:- Typically noisier and with more vibration.

- May require additional noise reduction measures.

8. Key Advantages and Disadvantages

- Advantages of Single-Stage Compressors:

- Lower upfront costs.

- Simpler design, easier maintenance.

- Best for low-to-medium pressure applications.

- Ideal for smaller operations with moderate air demand.

- Disadvantages of Single-Stage Compressors:

- Limited pressure output (typically up to 200 psi).

- Less energy-efficient for higher pressure applications.

- Not suitable for large-scale industrial needs.

- Advantages of Two-Stage Compressors:

- Higher pressure capacity (up to 300 psi or more).

- More energy-efficient at higher pressures.

- Suitable for demanding industrial applications.

- Better performance over a wide range of operating conditions.

- Disadvantages of Two-Stage Compressors:

- Higher initial purchase and installation costs.

- More complex maintenance and higher servicing costs.

- Larger footprint and more noise.

Conclusion

Choosing between a single-stage and two-stage screw air compressor depends largely on your operational requirements, budget, and long-term energy efficiency goals. Single-stage compressors are best suited for applications with moderate pressure needs and lower costs, while two-stage compressors excel in high-pressure, energy-efficient applications, offering greater performance and reliability for industrial-scale operations.

By carefully considering factors such as pressure requirements, energy efficiency, maintenance demands, and application scope, you can make an informed