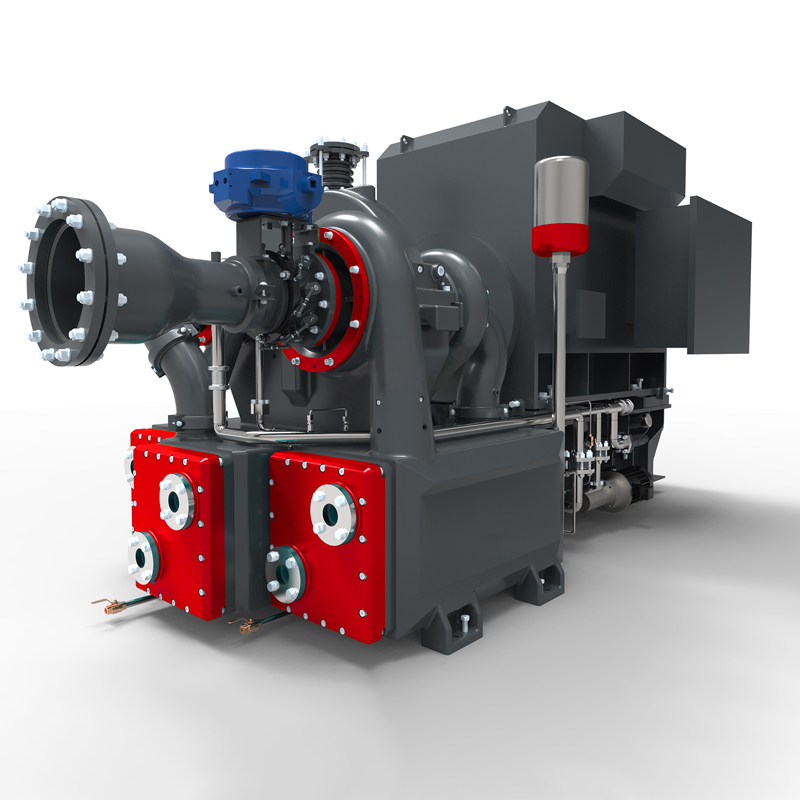

Centrifugal Turbo Air Compressor

Manufacturer and Supplier

A centrifugal compressor is a compressor in which the impeller does work on the gas to increase the pressure and speed of the gas and complete the gas transportation. The gas flows through the impeller in the radial direction. The centrifugal air compressor has a large air volume, simple and compact structure, lightweight. The operation is balanced, the operation rate is high, the friction parts are few, the maintenance cost and the personnel are few.

Moreover, turbo air compressor are widely used. Some basic chemical materials, such as propylene and ethylene, can be processed into important chemical products such as plastics and rubber. In the production of this basic raw material, the centrifugal compressor is one of the key pieces of equipment.

Unique Advantage

Outward scroll volute

Unique low-pressure loss and large flow area external volute design, compared with traditional centrifugal compressors:

- The traditional compressor volute flow channel is square or semicircular in design. When high-speed airflow impacts, the airflow will make many 90-degree turns, resulting in large aerodynamic losses.

- The cross-section of the volute flow channel of the AST compressor is designed in a circular shape, the spiral flow of the air flow does not have sharp turns, the pressure loss is smaller, and the energy saving effect of each compression stage can be increased by 1%.

Zero air consumption trap

- CFD optimal design and precision processing, precise sealing through condensation water in the valve body, achieving 100% zero air consumption;

- Mechanical structure, stable, reliable and long life;

- The outer casing is made of space aluminum, which is resistant to high temperatures and corrosion, and can withstand strong impacts;

- The valve core is precision made of stainless steel and does not rust. The valve body has a built-in large flow filter that is not easy to block;

- Easy to install, no auxiliary power required (no electricity, no driving air source, 100% mechanical);

- There are no electrical or pneumatic components, it is not easy to be short-circuited and damaged, and the maintenance cost is 0;

Cooler

- 35℃ cooling water design, more suitable for hot environments and situations with poor water quality

- Patented 3D flow channel (increases overall machine efficiency by about 1%-2%; conducive to hydrophobicity, no residual condensed water in the cavity)

- High cost zero air consumption trap, no compressed air leakage

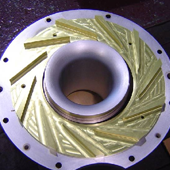

The unique seventh-generation high-balance gold impeller is equipped with a stainless steel deflector unit, which has higher corrosion resistance, avoids turbulent flow, and reduces overspeed blocking

The rotor has no thrust bearing anti-surge design, the rotor transmission has no relative sliding, high reliability gear transmission system, and the design life is 35 years

Diffuser and base material integrated patented linear diffuser, over-flow design, long-term operation, block prevention, design life of 30 years

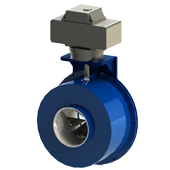

The IGV regulating valve has unique high reliability, the fork type is free of jamming, and is specially equipped with a dust cover.

Cooler cavity, special-shaped variable cross-section design, uniform flow field, low pressure drop design, low liquid effusion

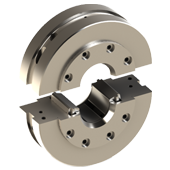

Rotor radial bearing, damping performance and automatic alignment function, horizontally split structure for easy maintenance

Technical Parameters

| Model | Pressure (bar) | Flow range (m3/min) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | ||

| SLT-300C | 0.6-9 | 24-48 | 132-263 | 2750 | 1500 | 1820 | 3800 |

| SLT-600C | 0.6-12 | 45-82 | 248-450 | 3280 | 1850 | 2200 | 6300 |

| SLT-900C | 0.6-12 | 76-122 | 400-640 | 3800 | 2000 | 2250 | 8160 |

| SLT-1200C | 0.6-12 | 118-150 | 630-800 | 4200 | 2150 | 2350 | 11500 |

| SLT-1500C | 0.6-16 | 118-228 | 760-1300 | 4200 | 2150 | 2350 | 12000 |

| SLT-2000C | 0.6-16 | 186-310 | 980-1600 | 4600 | 2200 | 2500 | 17200 |

| SLT-3000C | 0.6-16 | 268-438 | 1380-2250 | 5300 | 2300 | 2970 | 21500 |

| SLT-4000C | 0.6-25 | 347-550 | 1800-2850 | 6000 | 4500 | 3500 | 40000 |

| SLT-6500C | 0.6-25 | 530-920 | 2660-4540 | 8500 | 4200 | 4200 | 45000 |

| SLT-10000C | 0.6-30 | 830-1660 | 4060-7950 | 12000 | 5000 | 5300 | 65000 |

| SLT-20000C | 0.6-30 | 1780-3000 | 8980-15130 | 15000 | 6200 | 6000 | 80000 |

We Serivice for many customer

Sollant’s high-reliability and energy-saving centrifugal compressor product flow range covers: 25-1500m3/min, exhaust pressure range covers 0.8-32bar(g), various engineering machines and general-purpose standard machines. Committed to meeting various needs in the fields of steel, petroleum, chemical industry, new energy, automobile, ship, electronic equipment and machinery, food, pharmaceutical industry and public power supply engineering services, and providing efficient and high-quality services to customers around the world.

Keep us Update on Latest Air Compressor Newsletter

The Dynamics of Efficiency: Exploring Centrifugal Compressor in Modern Industry

In the heart of modern industrial operations lies a crucial component that fuels efficiency and productivity: centrifugal air compressors. These engineering marvels are essential tools that enable industries to harness the power of compressed air, a versatile and vital resource that drives a multitude of processes.

Efficiency stands as a cornerstone in industrial processes, dictating the balance between output, cost, and environmental impact. As industries strive to optimize their operations, the role of centrifugal air compressors becomes increasingly pivotal.

Efficiency, in the context of industrial processes, transcends mere productivity; it encompasses energy conservation, resource utilization, and the reduction of wasteful practices. It’s the key to not only enhancing output but also to minimizing the carbon footprint left by these operations. In this article, we delve into the intricate dynamics of how centrifugal air compressors contribute to efficiency within the diverse sectors of modern industry. From manufacturing to energy production, these machines play a transformative role that goes beyond mere air compression.

Understanding Centrifugal Air Compressors

Centrifugal air compressors, a marvel of engineering ingenuity, operate on a principle that transforms kinetic energy into pressurized air, driving a wide array of industrial processes. This principle hinges on the conversion of kinetic energy imparted by the rotating impeller into potential energy in the form of pressurized air.

At its core, the kinetic energy conversion process is rooted in the impeller’s high-speed rotation. As ambient air is drawn into the compressor, it enters the impeller’s center and is accelerated outward due to the impeller’s rapid circular motion. This acceleration results in an increase in the air’s kinetic energy.

Subsequently, the high-speed air is directed into a diffuser—a conical passage that gradually expands. This expansion converts the kinetic energy into potential energy, causing the air pressure to rise significantly. The air then flows into a volute casing, which further channels and compresses the air before it exits the compressor at the desired pressure level.

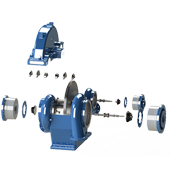

Key components within the centrifugal air compressor play integral roles in this process. The impeller, a rotating blade assembly, draws in and accelerates the incoming air. The diffuser, by providing a controlled expansion area, efficiently converts kinetic energy into potential energy, resulting in higher air pressure. The volute casing optimally directs the airflow, ensuring smooth compression and a consistent exit pressure.

Understanding this intricate interplay of components and principles is essential in grasping how centrifugal air compressors efficiently convert kinetic energy into the compressed air that powers a diverse range of industrial applications.

Efficiency as a Pillar of Modern Industry

In today’s highly competitive industrial landscape, efficiency has emerged as a fundamental pillar that shapes the success and sustainability of businesses. It transcends mere productivity, encompassing a holistic approach to operations that maximizes output while minimizing resource consumption and waste. The pursuit of efficiency is no longer just an operational choice; it’s a strategic imperative that directly impacts a company’s bottom line and reputation.

Energy consumption stands at the forefront of efficiency considerations. As industries strive to optimize their processes, the amount of energy utilized becomes a critical factor in determining operational costs and environmental impact.

The more energy-efficient a process or machine, the lower the associated operational expenses and carbon footprint. This holds particular significance in a world where sustainable practices are not just valued, but increasingly demanded by consumers and regulatory bodies alike.

This is where efficient air compression technologies like centrifugal compressors come into play. Centrifugal compressors, by converting kinetic energy into pressurized air in a highly efficient manner, align seamlessly with the goals of industrial sustainability. Their ability to deliver high-pressure air with minimal energy waste not only translates into reduced operating costs but also contributes to the reduction of greenhouse gas emissions—an essential step towards fulfilling environmental responsibilities.

As industries strive to strike a balance between economic growth and environmental stewardship, the adoption of efficient technologies becomes a pivotal choice.

Centrifugal air compressors, with their capacity to deliver both productivity and sustainability, exemplify the synergy between efficiency and environmental consciousness. By choosing such technologies, modern industries can drive their operations forward while contributing to a cleaner, more sustainable future.

Advantages of Centrifugal Air Compressors

Centrifugal air compressors offer a multitude of advantages, especially when viewed through the lens of efficiency. These advantages contribute to their prominent role in powering various industrial applications, from heavy manufacturing to precision operations. Let’s delve into the key benefits that make centrifugal compressors a prime choice for optimizing industrial efficiency:

- High Flow Rates and Pressure Ratios: Centrifugal compressors are renowned for their ability to handle large volumes of air and deliver high-pressure ratios. This capability is particularly advantageous in scenarios where consistent high airflow and elevated pressures are essential, such as in large-scale manufacturing processes or power generation.

- Energy-Efficient Conversion of Kinetic Energy: At the core of their efficiency lies the mechanism of converting kinetic energy into pressure energy. This conversion process is exceptionally energy-efficient, allowing industries to achieve desired air pressure levels without excessive energy waste. This energy efficiency translates directly into cost savings and reduced environmental impact.

- Minimal Vibration and Noise: Compared to other types of compressors, centrifugal air compressors exhibit minimal levels of vibration and noise. This is crucial in maintaining a comfortable and safe working environment, contributing to a healthier workplace and reduced downtime for maintenance or noise mitigation.

- Oil-Free Operation in Certain Configurations: In specific configurations, centrifugal air compressors can operate without the need for lubricating oil. This feature is vital in industries where oil contamination is a concern, such as pharmaceuticals, food processing, and electronics manufacturing. It ensures the integrity and quality of the end product while avoiding downtime for oil-related maintenance.

Applications across industries vividly demonstrate the advantages of centrifugal air compressors:

- Manufacturing: In automotive manufacturing, centrifugal compressors provide the high-pressure air needed for robotic operations, painting, and pneumatic tools, improving overall production efficiency.

- Energy Production: In power plants, centrifugal compressors facilitate gas turbine operations by delivering compressed air for combustion, enhancing power generation efficiency.

- Petrochemicals: Centrifugal compressors play a crucial role in the petrochemical industry by supplying compressed air for various processes, such as catalytic cracking and hydrogen production, ensuring optimal operational efficiency.

- Precision Engineering: Industries like electronics and semiconductor manufacturing rely on centrifugal compressors to deliver oil-free, contaminant-free air for delicate processes, maintaining product quality and precision.

In these applications and many more, the advantages of centrifugal air compressors shine brightly, elevating efficiency levels and optimizing industrial operations across the board.

Industrial Applications and Case Studies

Centrifugal air compressors find their prowess in a multitude of industries, each presenting unique challenges and demands that these compressors are well-equipped to address. Let’s delve into specific sectors where centrifugal compressors excel and explore real-world case studies that highlight their impact on efficiency:

- Petrochemical and Chemical Processing:

Centrifugal compressors play a vital role in petrochemical and chemical processing plants by providing the high-pressure air required for crucial operations. Case Study: A chemical plant needed to maintain precise pressure levels for reactor systems. By adopting centrifugal compressors, they achieved consistent pressure control, reducing fluctuations that had previously resulted in process disruptions and lower product quality.

- Power Generation:

Power plants heavily rely on centrifugal air compressors to facilitate combustion in gas turbines. These compressors deliver the compressed air needed for efficient and clean combustion, thereby enhancing power generation efficiency. Case Study: A natural gas power plant improved its combustion efficiency by integrating centrifugal compressors. This led to reduced fuel consumption and increased energy output, positively impacting both operational costs and environmental performance.

- Manufacturing and Automotive Production:

In the manufacturing and automotive sectors, centrifugal compressors contribute to increased productivity and precision. From pneumatic tools to robotic operations, these compressors ensure consistent air pressure for optimal production efficiency. Case Study: An automotive assembly line upgraded to centrifugal compressors, resulting in faster production cycles due to improved tool performance. The compressed air quality also prevented product defects caused by contaminants.

These real-world case studies underscore how centrifugal air compressors drive efficiency in diverse industries:

- Efficiency Gains in Petrochemicals: A petrochemical plant achieved energy savings of over 20% by replacing older compressors with modern centrifugal models. The compressors’ energy-efficient design resulted in reduced power consumption and lowered operational costs.

- Boosting Power Generation: An electricity provider increased gas turbine efficiency by over 3% by utilizing centrifugal compressors. The improved combustion process not only enhanced power generation but also reduced emissions.

- Precision and Speed in Manufacturing: An electronics manufacturer optimized its production line by switching to centrifugal air compressors. The consistent high-pressure air supply improved tool performance, resulting in a 15% increase in production throughput.

These examples highlight how centrifugal air compressors address industry-specific challenges and contribute to enhanced efficiency, proving their significance as key drivers of productivity and sustainable operations.

Innovations Driving Efficiency

The world of centrifugal air compressors is rapidly evolving, with technological advancements reshaping their design and capabilities. These innovations are revolutionizing the efficiency landscape by introducing cutting-edge features that enhance performance, adaptability, and sustainability. Let’s delve into recent advancements that are propelling centrifugal air compressors to new heights of efficiency:

- Variable-Speed Drives (VSD):

Variable-speed drives have emerged as a game-changer in centrifugal compressor design. Unlike traditional fixed-speed compressors, VSD-equipped compressors can dynamically adjust their motor speed to match the required air demand. This results in significant energy savings by avoiding the energy wastage associated with idling or excessive cycling. VSD technology ensures that the compressor operates at optimal efficiency across varying load conditions.

- Aerodynamic Improvements:

Innovations in aerodynamics have led to enhanced compressor impeller designs. These optimized impellers, crafted with precision, minimize losses and maximize energy conversion efficiency. Improved aerodynamics result in reduced energy consumption, leading to a more cost-effective operation while maintaining consistent air delivery.

- Smart Control Systems:

Modern centrifugal air compressors are integrated with advanced control systems that enable real-time monitoring and adjustment. These systems gather data on operating conditions and air demand, allowing for intelligent compressor control. By precisely modulating compressor output to match demand fluctuations, smart control systems ensure that energy consumption remains at an optimal level, thus boosting overall efficiency.

- Efficiency-Boosting Materials:

Innovations in materials science have led to the development of advanced materials for compressor components. These materials offer enhanced durability and corrosion resistance, resulting in longer operational lifespans. Additionally, reduced friction and wear within the compressor contribute to improved energy efficiency and reduced maintenance requirements.

These innovations translate into tangible benefits for efficiency:

- Energy Savings Through VSD: A manufacturing plant reduced energy consumption by 30% by implementing VSD-equipped centrifugal compressors. The ability to adjust compressor speed to match demand prevented energy wastage during low-demand periods.

- Precision and Reliability with Aerodynamics: An aerospace manufacturer improved production accuracy by utilizing aerodynamic impellers. The precise airflow control led to consistent tool performance and reduced production errors.

- Adaptability via Smart Control: A petrochemical facility optimized air production during varying demand cycles using smart control systems. This resulted in efficient energy usage and minimized operational costs.

As technological advancements continue to shape the future of centrifugal air compressors, their efficiency gains become ever more evident. These innovations are not only elevating industrial efficiency but also laying the foundation for a sustainable and dynamic future of compressed air solutions.

Energy Efficiency and Cost Savings

Centrifugal air compressors stand out as champions of energy efficiency, embodying features that not only reduce energy consumption but also lead to substantial cost savings for businesses. Let’s delve into the energy efficiency attributes of centrifugal compressors and the tangible cost benefits they bring:

- Reduced Energy Consumption:

Centrifugal air compressors are engineered for maximum energy efficiency. Their design minimizes energy losses by optimizing the kinetic-to-potential energy conversion process. This results in significantly lower energy consumption compared to other compressor types, directly impacting operational costs.

- Demand-Based Operation:

Centrifugal compressors excel at matching air supply with demand. By utilizing variable-speed drives and smart control systems, these compressors adjust their output based on real-time air requirements. This dynamic operation eliminates the energy wastage associated with running compressors at full capacity even during periods of low demand.

- Enhanced Load Matching Capabilities:

The adaptability of centrifugal compressors extends to their load matching capabilities. They can seamlessly handle varying air demand without sacrificing efficiency. This feature is particularly advantageous in industries where demand fluctuations are common, as it ensures optimal energy consumption at all times.

The energy efficiency features of centrifugal compressors translate directly into notable cost savings for businesses:

- Reduced Operational Costs: A manufacturing facility reduced its monthly energy bill by 25% after transitioning to centrifugal air compressors. The combination of demand-based operation and reduced energy consumption led to substantial ongoing cost savings.

- Enhanced Return on Investment: An industrial plant recouped its investment in centrifugal compressors within two years due to energy savings. The reduced energy costs contributed to a faster ROI and increased overall profitability.

- Lower Maintenance Expenses: In addition to energy efficiency, reduced wear and tear in centrifugal compressors lead to lower maintenance requirements. This, in turn, reduces maintenance costs and downtime, further contributing to cost savings.

By embracing the energy efficiency features of centrifugal air compressors, businesses can achieve measurable and sustainable cost reductions. The strategic decision to adopt these compressors not only drives immediate financial benefits but also aligns with the global trend towards energy-conscious and environmentally responsible operations.

Environmental Sustainability

The convergence of energy efficiency and environmental sustainability is a pivotal focus for modern industries, and centrifugal air compressors stand as instrumental players in this alignment. These compressors not only bolster efficiency but also contribute significantly to reducing carbon emissions and fostering a greener industrial landscape. Let’s delve into their role in promoting environmental stewardship:

- Reducing Carbon Emissions:

Energy-efficient centrifugal air compressors directly contribute to the reduction of carbon emissions. By consuming less energy during operation, they inherently emit fewer greenhouse gases into the atmosphere. This reduction in emissions not only benefits the environment but also aligns with regulatory requirements and sustainability targets.

- Sustainability Goals and Environmental Stewardship:

Modern industries are increasingly prioritizing sustainability and environmental stewardship. Centrifugal compressors, by virtue of their energy-efficient design, play a crucial role in helping industries achieve their sustainability goals. By minimizing energy consumption and carbon footprint, these compressors actively contribute to a cleaner, more responsible industrial operation.

- Alignment with Greener Practices:

The adoption of energy-efficient centrifugal air compressors reflects the broader trend of industries embracing greener practices. Businesses recognize that efficiency and sustainability go hand in hand, and as such, these compressors symbolize a proactive approach towards minimizing environmental impact while maintaining operational excellence.

The environmental sustainability brought forth by efficient centrifugal compressors is exemplified by real-world scenarios:

- Emission Reduction in Manufacturing: A steel manufacturing plant reduced its carbon emissions by 15% after transitioning to energy-efficient centrifugal compressors. The decreased energy consumption translated directly into fewer emissions, contributing to the company’s environmental targets.

- Meeting Green Certification Standards: An industrial facility achieved its green certification by implementing energy-efficient compressors. This allowed the facility to not only meet sustainability standards but also enjoy the associated reputational and marketing advantages.

- Sustainable Industrial Growth: A manufacturing consortium adopted energy-efficient compressors as part of their sustainability roadmap. This proactive stance not only reduced their collective carbon footprint but also positioned them as leaders in sustainable industrial practices.

As industries globally shift towards environmentally responsible operations, the role of energy-efficient centrifugal air compressors becomes increasingly vital. These compressors champion the cause of reducing carbon emissions, fostering sustainability, and aligning industrial practices with the global imperative of preserving our planet for future generations.

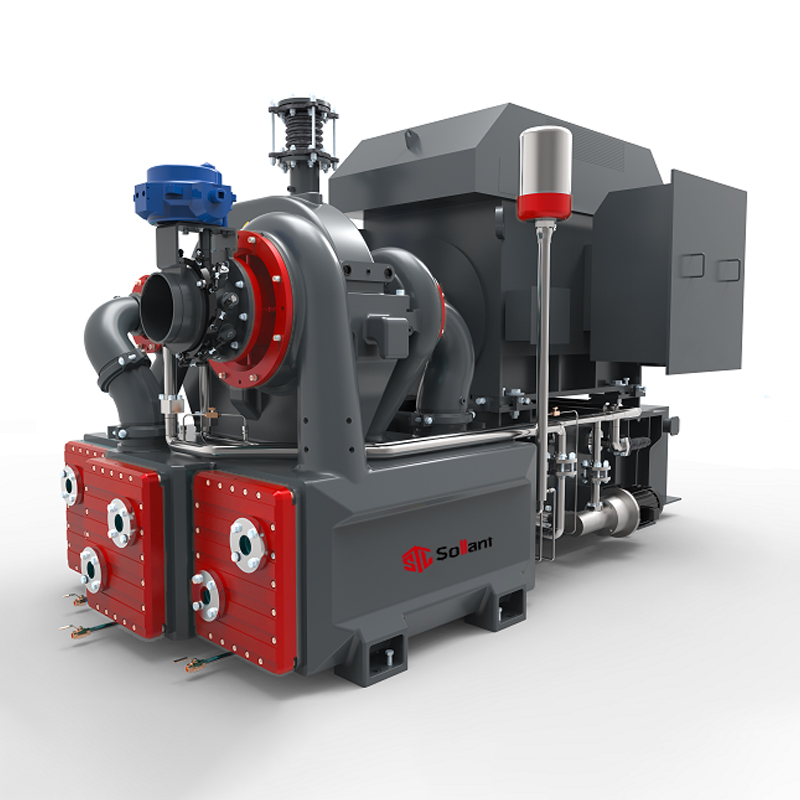

Sollant Centrifugal Compressor: Elevating Industrial Efficiency and Performance

In the realm of industrial air compression, Sollant stands as a beacon of excellence, offering innovative solutions that redefine efficiency and performance. As a specialized centrifugal air compressor supplier based in Turkey, Sollant has emerged as a driving force in the pursuit of optimized compressed air solutions for diverse industries. With a steadfast commitment to quality and innovation, Sollant is setting new standards for industrial air compression technology.

Sollant is a distinguished player in the world of centrifugal air compressors, characterized by its deep-rooted expertise and unwavering dedication to customer satisfaction. Established in Turkey, a hub of industrial innovation, Sollant has garnered a reputation for delivering cutting-edge solutions that empower industries to achieve superior operational efficiency.

At the heart of Sollant’s operations lies a relentless pursuit of innovation. Sollant’s centrifugal air compressors embody a perfect blend of advanced engineering, superior materials, and precision manufacturing. These compressors are designed to meet the unique demands of modern industries, where energy efficiency, reliability, and performance are paramount.

Efficiency lies at the core of Sollant’s offerings. Its centrifugal air compressors exemplify a synergy of engineering brilliance and advanced technologies. By harnessing the principles of aerodynamics and energy conversion, Sollant’s compressors achieve unparalleled efficiency levels, translating to tangible benefits for industries in terms of reduced energy consumption, minimized operational costs, and enhanced environmental responsibility.

What sets Sollant apart is its unwavering commitment to its customers. The company’s customer-centric philosophy drives it to understand the unique needs of each client and deliver solutions that align perfectly with those needs. Sollant’s team of experts collaborates closely with clients to ensure seamless integration and optimal performance of their centrifugal air compressors.

In the realm of industrial air compression, Sollant’s name resonates with excellence, innovation, and reliability. As a prominent centrifugal air compressor supplier in Turkey, Sollant is at the forefront of revolutionizing the way industries approach compressed air solutions. With a focus on efficiency, performance, and unwavering customer support, Sollant is not just a supplier, but a partner in elevating industrial efficiency to new heights.