SOLLANT AIR COMPRESSOR

Elevate Your F&B Creations with Pure Air: Air Compressors Are the Recipe for Success

Typical uses of compressed air in the food and beverage industry

- Pipelines transport liquids: milk, soy sauce, purified water, carbonated drinks, beer and rice wine, etc.

- During fermentation: Stirring of the liquid; introduction of air to increase the oxygen content. Such as: beer, rice wine, soy sauce and vinegar, etc.

- Mixing/stirring in a batching process: A method of passing a gas stream through a liquid to stir the liquid. Compressed air is generally used, and inert gases such as carbon dioxide and nitrogen are also used sometimes. Such as: soy sauce, vinegar, liquor blending.

- Gas filling in carbonated beverages: use a steel cylinder or a gas holder to introduce carbon dioxide. When the pressure of the carbon dioxide provided by the gas holder is low, it needs to be pressurized by the carbon dioxide gas compressor and then sent to the mixer.

- Air stretching: PET bottle production.

- Conveyor transmission device: such as slaughtering industry.

- Aseptic packaging: prepared under pressure with sterile air.

- Blowing materials to remove impurities: hair blowing in the slaughter industry, blowing minced meat, etc. Powder blowing and cleaning equipment in the biscuit industry. Correction in the baking process; air pressure is used to remove the wheat grains in the beer filtration process, etc.

- Extruded materials: In the beer industry, after the wort is cooled, sterile compressed air can be used to push out the wort in the sheet cooler; in the sugar industry, for filtration, sponges are squeezed to squeeze out the sugar juice. Drives the cylinder of the filling machine to produce linear motion.

- Inflatable packaging: It is suitable for the packaging of items with low vacuum requirements and a large amount of inflation.

The above processes will use factory gas, vacuum, high pressure or low pressure compressed air. Generally, this type of compressed air is mainly used in a series of production processes such as mixing, fermentation, bagging, blowing, drying, hot air tin spraying and pneumatic exhaust of raw materials.

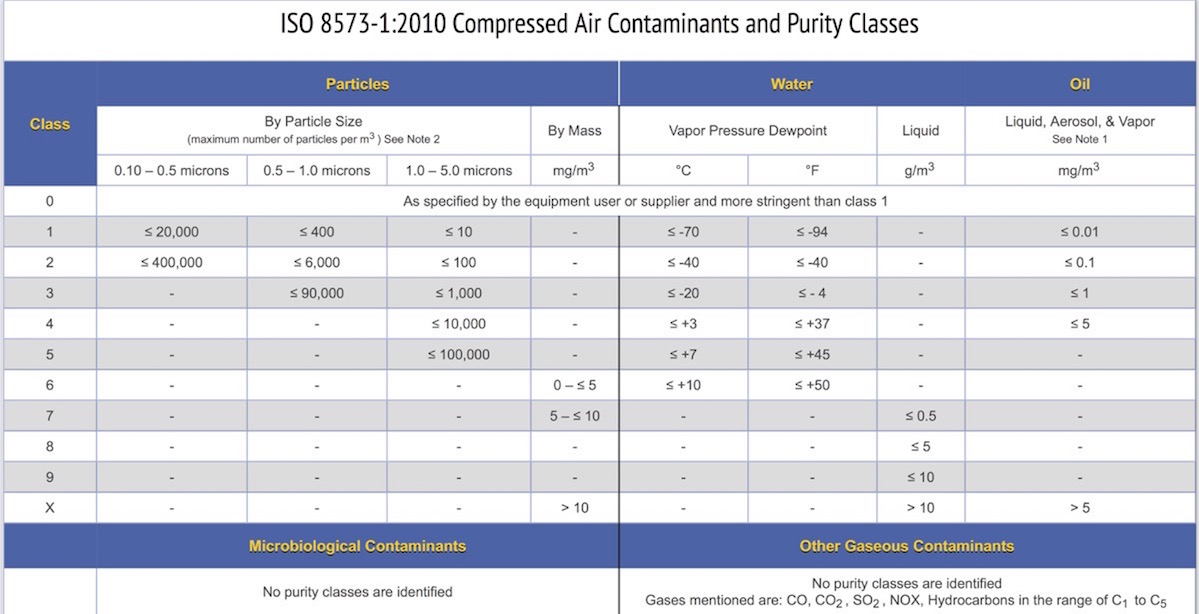

Compressed air must be degreased, sterilized, and deodorized. Oil-free compressed air is usually used as the air source, and then the compressed air is subjected to strict post-processing. In addition to sterilizing filters, the post-processing equipment also needs to be equipped with air purifiers. Water separator, high-efficiency precision filter, remove dust, water and oil in compressed air to prevent pollution and accidents. For this reason, the food and beverage industry is of paramount importance to compressed air quality.

Benefits of oil-free air compressor

Oil-free compressors offer several benefits, making them a preferred choice in various applications. Here are some key advantages of oil-free compressors:

- High Air Quality: Oil-free compressors deliver clean, contaminant-free compressed air, making them suitable for applications where air quality is critical, such as in the food and beverage, pharmaceutical, and electronics industries.

- Elimination of Oil Contamination: Since there is no lubricating oil in the compression chamber, oil-free compressors prevent the risk of oil contamination in the compressed air, ensuring product purity and safety.

- Reduced Maintenance: Oil-free compressors generally require less maintenance compared to oil-lubricated compressors. There is no need for oil changes, and the absence of oil also reduces the risk of oil leaks and related maintenance issues.

- Energy Efficiency: Oil-free compressors are designed for improved energy efficiency. They typically have better air-end designs and reduced internal friction, leading to lower energy consumption and operational costs.

- Quiet Operation: Many oil-free compressors are designed for quieter operation, making them suitable for noise-sensitive environments.

- Compliance with Regulations: Oil-free compressors meet regulatory standards and certifications related to air quality, ensuring compliance with industry-specific requirements.

While oil-free compressors offer numerous benefits, it’s essential to choose the right type and size of compressor for your specific application to maximize efficiency and performance.