SOLLANT AIR COMPRESSOR

Efficiency Meets Precision: Transform Your Laser Cutting with Screw Air Compressors

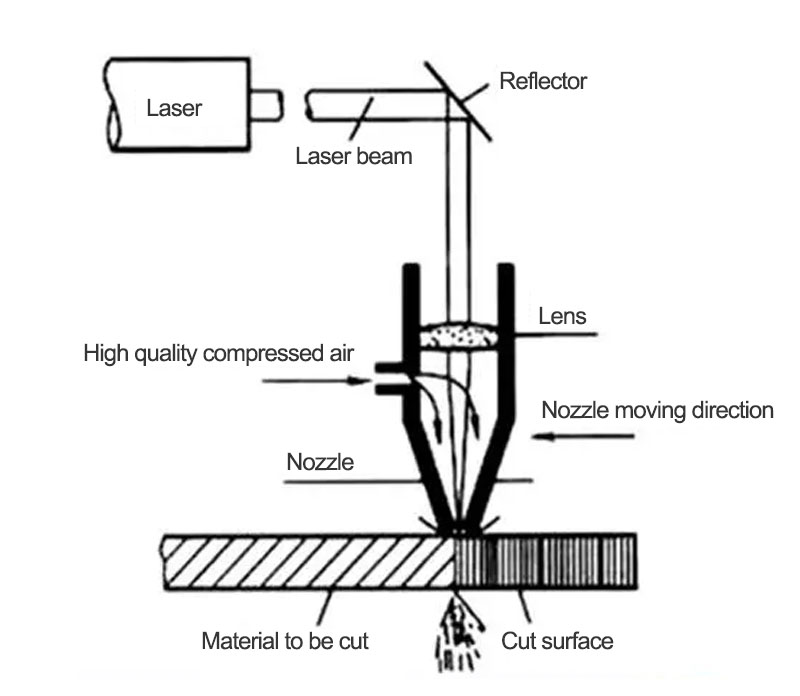

The laser cutting machine focuses the laser light emitted from the laser device into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and at the same time, the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

With the movement of the relative position of the beam and the workpiece, the material will eventually form a slit, so as to achieve the purpose of cutting. Laser cutting process replaces the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting speed, not limited by the cutting pattern, automatic typesetting to save material, smooth incision, and low processing cost. It gradually improves or replaces the traditional metal cutting process equipment.

Working principle of laser cutting machine

The laser cutting machine needs a pressurized gas source as power when it is working. Commonly used auxiliary gases include oxygen, nitrogen and compressed air, and sometimes argon. According to the gas pressure, it can be divided into high-pressure gas and low-pressure gas.

With the requirement of cutting plate thickness and efficiency, the pressure of compressed air has also developed from the previous 1.25MPa to 1.3MPa to a higher pressure, even reaching 2.0MPa to 3.0MPa. At present, the compressed air of 1.6MPa is mainly used in the market.

The key role of screw air compressor in the laser cutting industry:

- Auxiliary gas supply: During laser cutting, nitrogen, oxygen or other inert gases are usually used to assist cutting. The screw air compressor can provide high-pressure gas supply to ensure that these auxiliary gases are delivered to the laser cutting head with sufficient pressure and flow to support precise cutting operations.

- Cooling and Cleaning: Optics and lasers in laser cutting systems need to be kept at a stable temperature and in a clean environment to ensure optimal performance. Screw air compressors can provide cooling air to help maintain the temperature of the equipment and prevent the accumulation of dust and dirt by providing compressed air to clean the laser cutting head.

- Guided airflow: During the laser cutting process, it is usually necessary to guide the airflow to blow away the melted or evaporated material to ensure the cutting quality and precision. Screw compressors provide high-pressure air to maintain a steady, directed airflow that supports efficient material removal.

- Compressed air power supply: Some control systems and auxiliary equipment in laser cutting equipment may also need a compressed air power supply. Screw air compressors can provide reliable compressed air for these auxiliary equipment.

Selection of air compressor pressure and displacement

How thick the sheet metal can be cut by the air compressor of the laser cutting machine mainly depends on the laser power, and has little to do with the compressed air pressure. If the laser power is high enough, the compressed air pressure can cut even if it is low; if the laser power is not high enough, the compressed air pressure cannot be cut no matter how high it is.

As long as the laser power is large enough, the higher the compressed air pressure, the better the laser cutting quality and the higher the cutting efficiency. As the power of laser cutting air compressors develops from small power to medium power and then to high power and even super high power, the pressure requirements of air compressors supporting laser cutting machines have also increased from 8 bar at the beginning to 13 bar two years ago, and then increased Up to the current 16bar, and it is still developing towards 20-30bar.

For laser cutting machines that use compressed air as auxiliary gas, the compressed air is divided into three paths after being dried and purified, which are respectively used as cutting gas, cylinder power source and optical path positive pressure dust removal gas to maintain the normal operation of the laser cutting machine. Cutting gas The proportion is about 80-90% of the total consumption of compressed air. For a laser cutting machine that does not use compressed air but uses nitrogen or oxygen as an auxiliary gas, it still needs an air compressor with a small flow rate to provide the cylinder power source, but only a 6-7 bar atmospheric pressure source is required.

The quality of compressed air has a very direct impact on the quality of metal laser cutting, and the size and stability of the gas pressure will affect the cutting effect. Laser cutting machine users are generally equipped with four-stage filtration, or even five-stage filtration, in order to better protect the service life of the laser cutting machine.

If the water mist and oil contained in the compressed air are not cleaned, and the high pressure is sprayed onto the protective mirror surface of the laser cutting head, it will seriously affect the transmission of the laser beam, disperse the focus, cause the product to be cut through, and produce waste products. If it is a super-high-power laser cutting machine, as long as a little bit of oil film or water mist sticks on the surface of the protective mirror or nozzle, it may also cause high-energy laser emission to burn out the laser head.

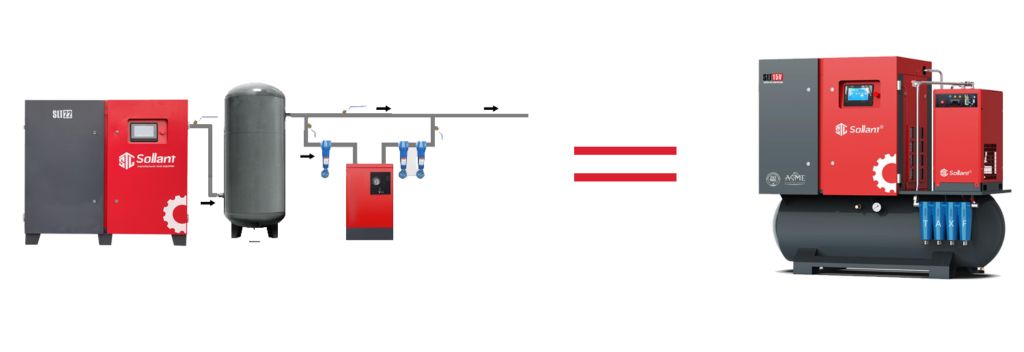

Since most users do not have the knowledge of air compressors and compressed air purification, if users purchase air compressors, air storage tanks, cold dryers and filters one by one and then install them by themselves, it will not only be troublesome, but also the entire system will be damaged. The required compressed air quality requirements cannot be met.

Sollant’s air compressor for laser cutting is a combination of compressor, air storage tank, water separator, cold dryer, and filter. It provides an integrated air compressor solution for laser cutting, eliminating the need for users to prepare air storage tanks, It is an ideal choice for the cold dryer and filter to be installed and taken over by the user on site, requiring multiple suppliers to provide services and other troubles.