Expert Portable Diesel Air Compressor Manufacturer Committed to Quality & Innovation

Maximizing Efficiency with Diesel Air Compressors

Get the best diesel-powered air compressors for construction, mining, and heavy-duty applications. Reliable, efficient, and built to last. Contact us for pricing and details!

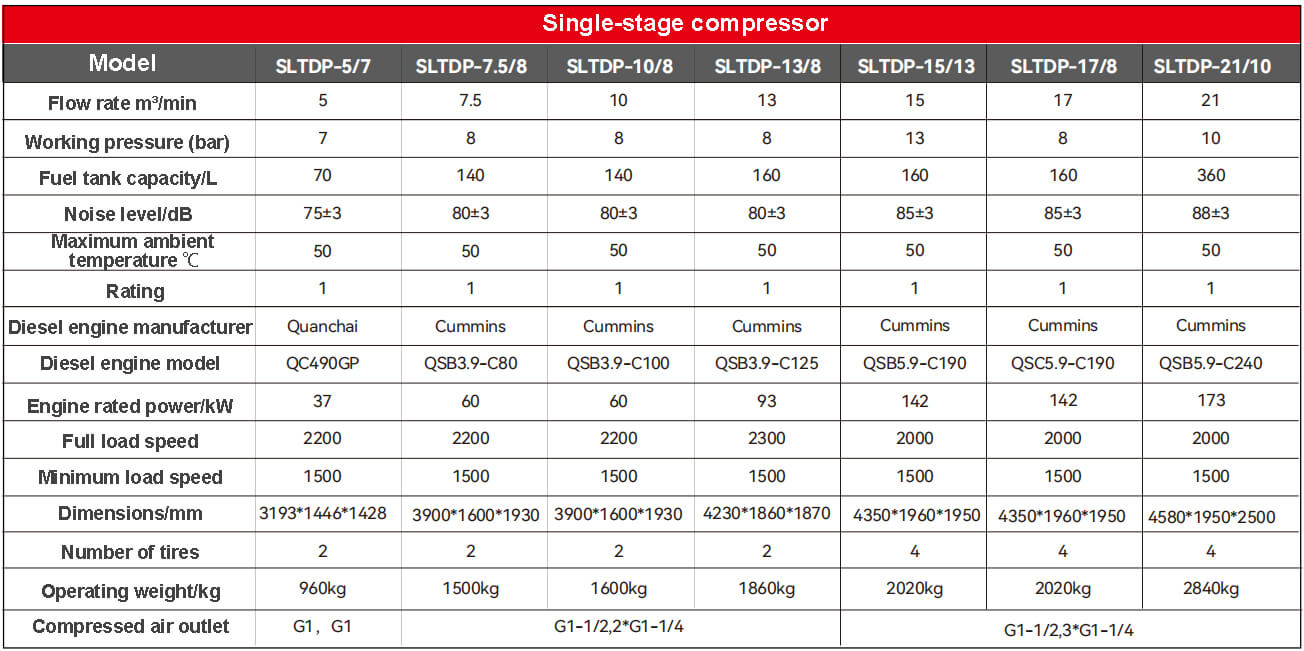

- Working Pressure: 7-35 bar

- Free Air Delivery: 185-1600 cfm

- Power: 26.8-429 kw

- Diesel Engine: Customization supported

- Certification: CE, ASME, EURO V

More Economical Configuration Options

The original imported Japanese Yanmar engine is more suitable for SOLLANT small mobile air compressors, bringing better fuel economy and lower noise.

Cummins diesel engines are used in SOLLANT medium and large mobile air compressors. The stronger power and more convenient maintenance services make it more convenient for our users to use.

Of course, we will also provide more options based on customer needs, such as domestic diesel engines and other brands. Rich configuration options are one of the customized services we are good at.

Diesel Portable Air Compressor Advantages

Maximum Versatility

The SLTDP is the ideal power choice for equipment such as construction machinery. The refined construction and high-quality components ensure trouble-free operation in ambient temperatures ranging from -20°C to +45°C. Its versatility is further enhanced by the chassis, which can be equipped with a fixed or height-adjustable tow bar and with or without overrunning brake. The fixed version can be mounted on a slide rail or machine stand.

Separate Air Filters for Engine and Compressor

The air filter is specifically tailored to the required air requirements, thus ensuring reliable system operation. Another important design detail is the electric fuel pump, which allows for quick and simple degassing of the diesel lines, eliminating the need for labor-intensive manual pumps.

Lightweight

Powerful doesn’t have to mean heavy: the SLTDP is very easy to maneuver and transport. In addition, its large diesel capacity ensures that the compressor has enough power to last a full work shift.

Optional Diesel Engine

The flexibly configured diesel engines can meet the needs of different operating environments and conditions, and the universal maintenance means that customers can find suitable parts suppliers no matter where the unit is located.

Simple to Operate

User-friendly icons and a single start switch with a preheat function are included. There is also a fully automatic monitoring and shutdown function for faults, while the pressure gauge and air temperature display make all information clear at a glance.

Local Team Customised & Support Air Compressor

Sollant Customer Feedback

Key equipment in transportation maintenance projects

Transportation facility maintenance companies often carry out emergency repairs in remote areas without stable electricity. Portable diesel air compressors are suitable for emergency work needs.

Agricultural machinery maintenance improves work efficiency

Agricultural machinery maintenance companies face power supply issues when working in the fields. Diesel portable air compressors ensure efficient work in an environment without electricity.

Mining Company Overcomes Harsh Environment

Mining companies operate in high-temperature and dusty environments, where electric air compressors cannot operate reliably. Sollant provides air compressors that are resistant to high temperatures and dust, ensuring that the equipment can operate efficiently for a long time.

Improve construction efficiency at construction sites

Frequent air compressor failures at construction sites affect the progress of the project. Diesel portable air compressors are suitable for sites without power supply, ensuring a continuous and stable air supply.

Building facility maintenance improves construction safety

Building facility maintenance companies are responsible for providing daily equipment inspections and emergency repair services for multiple construction sites, with unstable power supply. Construction compressors support the use of various maintenance tools.

Metal processing plants use sandblasting to remove oxides

Metal processing plants use sandblasting to remove metal oxides, and the power supply is unstable. Diesel portable air compressors ensure stable operation of sandblasting equipment.

Keep us Update on Latest Air Compressor Newsletter

Energy saving and environmental protection: innovative technology of modern diesel air compressor

As an important industrial equipment, diesel air compressors are widely used in various high-intensity working environments, especially in construction sites, mines, manufacturing, and oil and natural gas. In these fields, diesel air compressors are mainly responsible for providing compressed air to drive various pneumatic tools and equipment to support the smooth progress of production operations. For example, on construction sites, diesel air compressors can provide power for equipment such as concrete sprayers, pneumatic drills, and pile drivers; in mines, it provides stable air power support for heavy machinery such as drilling and crushing; in manufacturing, diesel air compressors provide power for pneumatic tools, spraying equipment, etc. on the production line to ensure production efficiency and quality.

However, although diesel air compressors are indispensable in industrial production, their traditional operating mode also brings some problems that cannot be ignored. With the increasingly stringent global environmental regulations and the continuous improvement of energy efficiency requirements, diesel air compressors are facing increasing pressure in terms of energy efficiency and environmental protection. Problems such as high fuel consumption, serious emission pollution, and high noise of diesel engines have forced many industries to re-examine their use methods and find more environmentally friendly and energy-saving solutions.

In this context, energy conservation and environmental protection have become the core goals of the development of modern diesel air compressor technology. In response to increasingly stringent environmental regulations, rising energy costs and social attention to green production, more and more diesel air compressor manufacturers have begun to invest a lot of resources in technological innovation to improve the energy efficiency of their products and reduce environmental impact. This not only helps to reduce operating costs, but also meets the requirements of governments and enterprises for sustainable development.

This article will explore in depth how modern diesel air compressors have made breakthroughs in energy conservation and environmental protection through a series of innovative technologies. By analyzing energy-saving technologies, environmental protection technologies and future development trends, we will reveal the direction of technological evolution in this field and provide useful references for industry practitioners. Specifically, this article will discuss how diesel air compressors use technologies such as variable speed drives, high-efficiency compressor design, and intelligent control systems to optimize energy utilization efficiency; at the same time, how to reduce negative impacts on the environment through low-emission technologies, noise control, and waste heat recovery.

Energy-saving technology of diesel air compressor

As a high-energy-consuming equipment, the energy efficiency improvement of diesel air compressors is of great significance in industrial applications. With the increasingly stringent global energy-saving and emission-reduction requirements, the shortcomings of traditional diesel air compressors in terms of energy efficiency have gradually been exposed. Therefore, many manufacturers have introduced a variety of innovative energy-saving technologies to promote the development of diesel air compressors in a more efficient and environmentally friendly direction. The following are some of the main energy-saving technologies used in modern diesel air compressors.

1. Variable Speed Drive Technology (VSD)

Basic Concepts of Variable Speed Drive Technology

Variable Speed Drive Technology (VSD), also known as variable frequency drive technology, is an energy-saving technology that achieves load adaptation by adjusting the speed of the motor. Unlike traditional fixed speed drive systems, VSD can adjust the operating speed of the diesel air compressor in real time according to actual needs, thereby optimizing power output and avoiding energy waste.

In traditional air compressors, the compressor runs at a fixed speed and continues to consume the same energy regardless of whether the load changes or not. This fixed operation mode not only leads to energy waste, but also makes the mechanical equipment frequently in an inefficient state when lightly loaded. After adopting VSD technology, the air compressor can detect the load demand in real time and automatically adjust the speed according to the load changes to ensure that the compressor only provides sufficient air pressure when needed to avoid excessive energy consumption.

Application of VSD in Diesel Air Compressors and Energy Saving Effects

The VSD technology of diesel air compressors is mainly used to adjust the engine speed and the airflow output of the compressor. By installing a frequency converter, the diesel air compressor can automatically adjust the engine speed according to the changes in the operating load to match it with the load demand. This technology allows diesel air compressors to reduce their operating speed when under low load or idle, thereby saving fuel consumption.

According to multiple studies and actual application data, the application of VSD technology in diesel air compressors can usually save 15% to 35% of energy, especially when the load fluctuates greatly. Through this technology, the energy efficiency of diesel air compressors is greatly improved, which not only reduces the operating costs of enterprises, but also helps reduce unnecessary greenhouse gas emissions.

Reduce energy waste by adjusting the compressor speed to match the actual load

One of the most important advantages of VSD technology is that it can intelligently adjust the compressor speed according to the actual load conditions. For example, under light load working conditions, the air compressor speed will automatically decrease, thereby reducing fuel consumption. On the contrary, when the load is heavy, the system will automatically increase the speed to ensure stable air supply. This dynamic adjustment greatly reduces energy waste, especially in scenarios where the air compressor load is uneven or intermittent demand is large, and the energy saving effect is particularly obvious.

2. High-efficiency and energy-saving compressor design

Improved airflow design: Optimize the airflow path of the compressor to reduce energy loss

In addition to VSD technology, another major energy-saving innovation of modern diesel air compressors lies in efficient air flow design. Traditional air compressors will produce air flow resistance and pressure loss during the compression process, which will lead to energy loss. To solve this problem, manufacturers reduce unnecessary airflow friction and resistance by optimizing the airflow path of the compressor. This optimized design ensures that air can pass through various components more smoothly, thereby improving compression efficiency and reducing energy consumption.

For example, the use of an efficient air intake system and low-resistance airflow channel design can greatly reduce the turbulence that may occur during the bending and compression of the airflow. This not only improves the operating efficiency of the compressor, but also reduces the loss of compressed air during the flow process.

Enhanced compression efficiency: Improved air compression efficiency through improved turbine and cylinder design

Improving the working efficiency of the compressor is also the key to achieving energy saving. Through the optimized design of the turbine and cylinder, modern diesel air compressors can significantly improve air compression efficiency. For example, by increasing the number of turbine blades and improving their angles, the energy of the fuel can be converted more effectively and the compression efficiency can be improved. At the same time, optimizing the design of the cylinder can also reduce heat loss and further improve energy efficiency.

Some advanced diesel air compressors also use a two-stage or multi-stage compression system, which can gradually increase the air pressure in multiple stages to maximize the compression efficiency of each stage. This multi-stage compression technology not only improves the overall efficiency of the air compressor, but also effectively controls the energy consumption during the entire compression process.

Use efficient materials: reduce friction and heat generation, further improving energy efficiency

The use of high-efficiency materials is also an important way to improve the energy-saving performance of diesel air compressors. By using low-friction, high-wear-resistant materials to manufacture important components (such as bearings, pistons, turbine blades, etc.), friction losses and heat generation can be effectively reduced. These high-efficiency materials can ensure that the air compressor maintains higher mechanical efficiency and reduces energy waste during operation.

For example, components made with advanced ceramic coatings or composite materials can significantly increase durability and productivity. By reducing mechanical friction, the energy efficiency and reliability of air compressors are significantly improved, while also reducing equipment maintenance needs and operating costs.

3. Intelligent control system

Introduction to how intelligent control systems optimize the operating status of machines

With the development of the Internet of Things and artificial intelligence technologies, intelligent control systems have become one of the standard configurations of modern diesel air compressors. These systems can monitor the operating status of the equipment in real time and optimize the operating parameters of the compressor through algorithms, thereby improving energy efficiency.

Intelligent control systems can obtain various operating parameters of the compressor (such as pressure, temperature, speed, etc.) in real time by integrating sensors, data acquisition devices and remote control functions. Through these data, the system can predict the operating status of the equipment and automatically adjust the operating parameters to adapt to different workloads. This intelligent regulation not only improves the energy efficiency of the equipment, but also avoids human operating errors and unnecessary energy waste.

Real-time monitoring and adjustment of power output to avoid idling and ineffective energy consumption

Another key function of the intelligent control system is to monitor and adjust the power output of the air compressor in real time. By analyzing load changes, the intelligent system can automatically reduce power output when the equipment is underloaded or idling, thereby avoiding idling and ineffective energy consumption. This precise power regulation significantly improves the energy efficiency of the system.

In some high-end diesel air compressors, the intelligent control system can also be linked with the automation system of the entire production line to accurately adjust the quantity and pressure of air compression according to production needs, ensuring that the best working state can be provided at any time to avoid energy waste.

Cooperate with the overall automation system of the equipment to improve the overall energy management level

Modern diesel air compressors are often deeply integrated with the automation system of the production line. The intelligent control system not only controls the operation of a single device, but also coordinates multiple devices and production links to optimize overall energy management. For example, the air compressor can be connected to the energy management system of the workshop and automatically start or stop according to the actual needs of production, thereby maximizing energy savings.

This overall coordinated energy management mode not only improves the energy efficiency of a single device, but also comprehensively optimizes the energy consumption of the entire production process, further reducing waste and reducing operating costs.

4. Energy saving mode and load adjustment

Automatically adjust the working mode according to changes in working conditions, such as “load-no load” mode

Many modern diesel air compressors adopt energy-saving mode and load adjustment technology to adapt to energy efficiency needs under different working conditions. The load regulation system can automatically switch the working mode of the air compressor according to changes in compressed air demand. For example, under low load conditions, the air compressor can enter “no load” mode, consuming very little energy, and under high load conditions, it can automatically adjust to full load operation.

Through this load adjustment technology, the diesel air compressor can adapt to environmental changes in real time, avoid ineffective energy consumption, and ensure that the working pressure and flow rate meet actual needs.

How energy-saving mode reduces unnecessary fuel consumption and energy waste

Energy-saving mode significantly reduces fuel consumption and energy waste by reducing the energy consumption of the machine during off-peak operation. For example, when the production load is low or when the machine is shut down and waiting, the air compressor will automatically reduce the engine speed or enter sleep mode. This process not only reduces fuel consumption, but also reduces the burden on mechanical parts and extends the service life of the equipment.

In general, modern diesel air compressors can significantly improve energy efficiency, reduce energy consumption and operating costs through the application of these energy-saving technologies, and bring higher economic and environmental benefits to enterprises.

Environmental protection technology of diesel air compressor

With the increasingly stringent environmental regulations and the focus on sustainable development, diesel air compressor manufacturers have made a lot of innovations and improvements in environmental protection technology. In order to reduce the impact on the environment, modern diesel air compressors not only focus on improving energy efficiency, but also adopt a series of technologies to reduce harmful emissions, noise pollution and energy waste. The following are common environmental protection technologies in diesel air compressors.

1. Low emission technology

Use low emission engines (such as engines that meet Euro IV/Euro V standards)

Low emission technology is the key to reducing environmental pollution in diesel air compressors. In order to meet the increasingly stringent emission standards around the world, especially the European Euro IV and Euro V emission standards, the engine design of diesel air compressors is constantly optimized to reduce harmful gas emissions. By improving the combustion system, optimizing the engine structure and introducing advanced fuel injection technology, modern diesel air compressors can effectively reduce the emission of nitrogen oxides (NOx), hydrocarbons (HC) and carbon monoxide (CO).

For example, the Euro IV and Euro V standards require that the nitrogen oxide emissions of diesel engines must be greatly reduced when working. These standards have promoted the application of more sophisticated fuel injection control systems and advanced engine management technologies, so that the engine can maintain higher combustion efficiency at high or low loads and reduce the generation of pollutants.

SCR (Selective Catalytic Reduction) technology, DPF (Diesel Particulate Filter) and other technologies reduce nitrogen oxide and particulate matter emissions

In addition to optimizing the engine itself, modern diesel air compressors also use advanced emission after-treatment technologies such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) to further reduce the emission of harmful substances.

- SCR technology: SCR technology uses a urea solution (also known as DEF, diesel exhaust fluid) to convert nitrogen oxides (NOx) into harmless nitrogen and water vapor. The SCR system injects a urea solution into the exhaust gas, which reacts and converts nitrogen oxides into harmless substances under the action of a catalyst. This technology can significantly reduce NOx emissions and is especially suitable for diesel air compressors under high load or high emission conditions.

- DPF technology: DPF technology captures and removes solid particles (such as carbon particles) in diesel engine emissions by installing a particulate filter. These filters can effectively reduce PM (particulate matter) emissions and meet increasingly stringent environmental regulations. The DPF system not only reduces air pollution, but also extends the service life of the engine and reduces negative impact on the environment.

Improved combustion efficiency and reduced carbon footprint

Improving combustion efficiency is one of the core aspects of reducing carbon emissions. Modern diesel air compressors improve fuel utilization by optimizing the combustion process. Advanced combustion control systems and precise fuel injection technology ensure that diesel is fully burned in the engine, thereby reducing emissions of unburned fuel. This not only reduces hydrocarbon emissions, but also greatly reduces carbon dioxide (CO₂) emissions and reduces carbon footprint.

More efficient combustion not only helps reduce harmful emissions, but also helps improve fuel economy, thereby reducing overall energy consumption and production costs.

2. Noise control technology

Silent design: Reduce operating noise by optimizing the compressor housing and shock absorption system

Noise pollution is another important problem faced by diesel air compressors in industrial environments. In order to reduce the impact of noise on workers and the surrounding environment, modern diesel air compressors use a variety of silent design technologies. By optimizing the structure of the compressor housing and reducing vibration and airflow noise, the noise level during equipment operation can be effectively reduced.

- Shell design: The air compressor shell is made of materials with high sound insulation performance, and the transmission of noise sources is reduced through precise structural design.

- Shock absorption system: The built-in shock absorption system can effectively absorb and isolate the vibration of the equipment, prevent the vibration from being transmitted to the shell, and thus reduce external noise.

These silent designs not only improve the comfort of the operating environment, but also help companies comply with relevant noise emission regulations, especially in places that require 24-hour continuous operation.

The application of mufflers and sound insulation materials meets the noise emission standards of environmental regulations

Mufflers and sound insulation materials are another important technical means to reduce noise. By installing mufflers in the exhaust pipe and intake system, diesel air compressors can effectively reduce the noise during engine operation. At the same time, the use of efficient sound insulation materials to cover the external shell further reduces the spread of noise and ensures that the equipment can meet the increasingly stringent noise emission standards.

Many diesel air compressors can now achieve noise standards below 60 decibels (dB), which is much lower than the 80-90 decibels common in traditional diesel air compressors. This makes the use of air compressors in noise-sensitive areas such as urban construction and mining operations more feasible.

3. Waste heat recovery technology

Recover waste heat generated during the operation of diesel air compressors

Diesel air compressors generate a lot of waste heat when working, which is usually wasted, resulting in low energy efficiency. In order to improve energy efficiency, modern diesel air compressors have introduced waste heat recovery technology to convert waste heat into useful energy. The waste heat recovery system captures the heat generated by the engine or compressor through a heat exchanger and uses it to heat water, air conditioning systems or other production processes.

This waste heat recovery can not only reduce the energy consumption of the air compressor, but also provide a free heat source for the production process, reduce the energy cost of the enterprise, and improve the overall energy efficiency.

After waste heat recovery, it can be used to heat water or heating systems, further improving the overall energy efficiency

A common application of waste heat recovery is to use waste heat to heat water or heating systems. In cold climates, the waste heat generated by diesel air compressors can be used to heat factory water or provide heating for workshops, which greatly reduces the additional energy consumption required for heating. Especially in cold winters, the reuse of waste heat saves energy and improves the overall energy efficiency of air compressors.

Through this technology, diesel air compressors can not only provide stable air pressure output during operation, but also support other energy needs of enterprises such as heating and hot water supply to a certain extent, achieving multiple benefits.

4. Environmentally friendly lubricants and fuels

Use low-pollution, low-viscosity environmentally friendly lubricants to reduce the impact of oil on the environment

The application of environmentally friendly lubricants and fuels is another key area in the environmental protection technology of modern diesel air compressors. Traditional diesel air compressors often use ordinary lubricants, which will produce waste oil, leakage and pollution during use. Modern environmentally friendly lubricants use low-pollution, low-viscosity formulas to reduce the impact of oil on the environment.

Environmentally friendly lubricants can not only effectively reduce the friction and wear of air compressors, but also reduce waste oil emissions and reduce pollution to soil and water sources. The use of these lubricants reduces the environmental burden of air compressors and improves the operating efficiency and reliability of equipment.

Use of new bio-based or synthetic fuels to reduce air pollutant emissions

In addition, the use of new bio-based fuels and synthetic fuels is also increasingly used in diesel air compressors. These fuels are usually made from renewable resources (such as vegetable oils, animal fats or waste greases), and not only have lower carbon emissions and sulfur content, but also reduce air pollutant emissions.

By using bio-based or synthetic fuels, the overall emission level of diesel air compressors has been effectively reduced, especially in reducing emissions of carbon dioxide, nitrogen oxides and particulate matter. These new fuels can help companies better meet environmental protection requirements and reduce environmental impact while reducing fuel costs.

Effectively utilize waste heat through heat exchangers and other equipment to reduce energy waste

In modern diesel air compressors, heat exchangers are important equipment for waste heat recovery. Heat exchangers transfer waste heat to where it is needed through an efficient heat conduction process, and distribute heat to other equipment or facilities through a circulating water system. Using heat exchangers to recover waste heat can greatly improve energy utilization and avoid energy waste.

Sustainable Development and Future Prospects of Diesel Air Compressors

With the improvement of global environmental awareness and the acceleration of energy transformation, the diesel air compressor industry is also undergoing a profound change. In order to meet the increasingly stringent environmental regulations and the market demand for green and energy-saving products, the technological innovation of diesel air compressors is moving towards a more sustainable and low-emission direction. In this process, the integration of new energy technologies, the application of digital and remote monitoring technologies, and policy promotion are driving diesel air compressors to evolve in a more efficient and environmentally friendly direction. The following will explore in depth the future prospects of diesel air compressors in sustainable development.

1. Integration of emerging energy technologies

Combination of new energy such as solar energy and hydrogen energy with diesel air compressors

With the increasing global attention to renewable energy, emerging energy such as solar energy and hydrogen energy has gradually become an important supplement to traditional diesel air compressors. Especially in remote areas, construction sites or mines, diesel air compressors often face the problem of insufficient or unstable power supply. By combining with new energy systems such as solar energy or hydrogen energy, it can effectively reduce dependence on traditional diesel and reduce emissions of carbon dioxide and other pollutants.

For example, in some large construction sites, solar panels can provide a stable power supply for air compressors, especially during the sunny hours of the day, when solar energy can provide sufficient power for diesel air compressors, thereby reducing the use of diesel. Through this hybrid solution of new energy and diesel air compressors, it can not only ensure the continuity of operations, but also significantly reduce emissions and improve energy efficiency.

Hydrogen energy, as a clean energy, has high energy density and zero emissions. In the future, hydrogen-powered air compressors will likely become an innovative option, especially in industrial sites that require high pressure and high power output. Combining hydrogen energy with diesel air compressors can achieve long-term and efficient work without relying on traditional fossil fuels.

The application of hybrid power systems reduces dependence on traditional diesel

The application of hybrid power systems is a major trend in the future development of diesel air compressors. By combining internal combustion engines (diesel engines) with electric drive systems, hybrid air compressors can flexibly switch operating modes according to load requirements, maximize energy efficiency, and reduce fuel consumption. Under low load or short-time operation, the electric drive can work alone, reducing dependence on diesel; while under high load or long-time operation, the diesel engine plays a major role and provides stable power output.

This hybrid system can not only significantly reduce the fuel consumption of diesel air compressors, but also reduce greenhouse gases and harmful emissions, in line with increasingly stringent environmental regulations in various countries.

The coordinated work of electric and diesel air compressors improves overall efficiency

In the future, the coordinated work of electric and diesel air compressors will also become a common operating mode. Under some working conditions, the electric air compressor can complete the work independently, while the diesel air compressor can be used as a backup or started under high load. Through the coordinated operation of the two, energy consumption can be minimized and overall production efficiency can be improved without sacrificing operating efficiency. This system integration will not only improve the energy efficiency of the air compressor, but also reduce the maintenance cost of the entire operating system to a certain extent and extend the service life of the equipment.

2. The impact of digitalization and remote monitoring

Real-time monitoring of equipment status and optimization of energy use through IoT technology

With the rapid development of IoT technology, digitalization has become an important trend in the diesel air compressor industry. By embedding sensors and data acquisition systems into air compressor equipment, IoT technology can monitor various operating parameters of the equipment (such as compressed air demand, oil temperature, pressure, speed, etc.) in real time and transmit these data to the cloud for processing and analysis. This enables operators to obtain equipment status at any time through smart devices, optimize energy use, predict equipment maintenance needs in advance, and avoid unnecessary energy waste.

For example, when the load of the air compressor changes, the system can adjust the operating mode according to actual needs to ensure that the air compressor always works in the best energy efficiency state. Through real-time data monitoring, enterprises can accurately grasp the energy efficiency performance of the equipment, so as to take corresponding energy-saving measures and further improve energy utilization.

Remote diagnosis and fault warning to reduce equipment energy consumption and downtime

The application of remote diagnosis and fault warning system makes the maintenance and management of diesel air compressors more intelligent and efficient. By analyzing real-time monitoring data, the intelligent system can predict potential equipment failures and issue alarms in advance. This not only reduces equipment downtime, but also prevents excessive energy consumption and unnecessary energy waste caused by equipment failure.

In addition, the remote control function allows maintenance personnel to adjust and maintain the equipment through the network without visiting the site, reducing ineffective energy consumption and maintenance costs during equipment operation.

3. Green certification and policy promotion

The role of environmental protection policies and green certification standards in various countries in promoting the technological innovation of diesel air compressors

As environmental regulations become increasingly stringent, governments and environmental protection organizations around the world are constantly promoting the development of green and low-emission technologies. Governments have introduced policies to encourage companies to adopt environmentally friendly technologies to reduce energy consumption and pollution emissions. For example, Europe’s Euro IV, Euro V and Euro VI emission standards require diesel air compressors to meet stricter emission requirements; the US EPA (Environmental Protection Agency) has also introduced similar emission restriction policies. These policies have promoted the innovation of diesel air compressor technology and accelerated the research and development and application of low-emission and energy-saving air compressors.

In addition, more and more environmental certifications (such as ISO 14001, CE certification, etc.) have also become important passes for corporate products to enter the market. Obtaining green certification not only helps companies establish an environmentally friendly image, but also wins the trust of consumers and obtains government subsidies and tax incentives.

Continuously improve product environmental performance to meet stricter market demands

With the continuous improvement of environmental regulations and the upgrading of market demand, diesel air compressor manufacturers are under pressure to continuously improve the environmental performance of their products. To meet these needs, manufacturers are constantly promoting technological innovation in diesel air compressors, from low-emission engine design to high-efficiency waste heat recovery systems to more advanced noise control technologies.

By increasing investment in the research and development of environmental protection technologies, diesel air compressor companies can not only meet the current market’s environmental protection needs, but also stand out in the fierce market competition. In addition, companies also need to continuously optimize product performance, improve production processes and product life cycle management to ensure that the equipment can continue to maintain low energy consumption, low emissions and high efficiency during use.

The sustainable development of diesel air compressors is not only the optimization of existing technologies, but also the active integration of emerging technologies. With the introduction of new energy technologies, the widespread application of digitalization and remote monitoring, and the promotion of environmental protection policies, future diesel air compressors will be more efficient, green, and intelligent. Through these technological advances, diesel air compressors will reduce the negative impact on the environment while ensuring industrial production efficiency, and promote the development of global industrial equipment in a more sustainable and environmentally friendly direction.

With the continuous advancement of technology and the increase in market demand for environmental protection and energy saving, the future prospects of diesel air compressors will be broader, contributing more to promoting the green transformation of global industry and manufacturing.