Regeneration gas volume: ≤14%~20%

Working pressure: 0.6~1.0Mpa

Intake oil content: ≤0.1mg/m³

Product gas pressure dew point: -20℃~-40℃

Desiccant: activated alumina

Working cycle: 10~20 minutes

Intake temperature: 0℃~45℃

Power supply: 220V/50Hz

Sollant Heatless Adsorption Dryer Manufacturer

» Features

- Large-sized tower body ensures air flow rate and contact time

- High-performance adsorbent with stable performance and long service life

- Large displacement muffler

- Stainless steel check valve, air diffuser

- Electrical box IP54

» Reliable design

- Supporting ceramic balls are used at the bottom of the adsorption tower to make the air distribution more uniform, which can prevent the adsorbent at the bottom from soaking in water and prolong the life of the adsorbent;

- With the specially designed stainless steel shunt, the pressure loss can be greatly reduced.

- Special customized high-performance adsorbent can achieve excellent dew point.

- The standard configuration of the whole series is a high-performance pneumatic valve, and its reliability and pressure loss during operation are much better than that of diaphragm valves and solenoid valves.

- The standard configuration is the high-efficiency oil removal and dust removal filter for air control valve control.

» Working principle

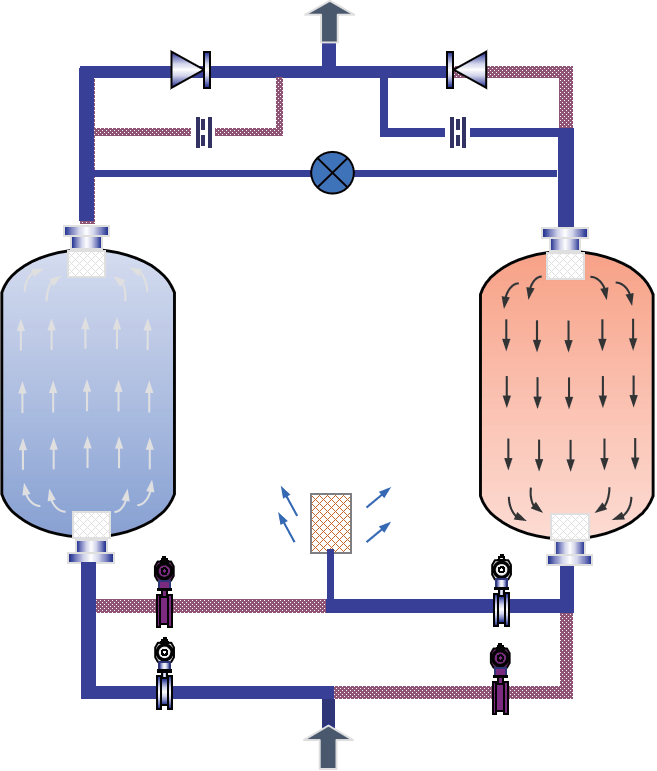

The heatless regenerative adsorption dryer uses “pressure swing adsorption” to achieve the drying effect. Since the ability of the air to hold water vapor is inversely proportional to the pressure, a part of the air after drying (called regeneration gas) decompresses and expands to atmospheric pressure. This pressure change makes the expanded air drier, and then it flows over the desiccant layer that is not connected to the airflow to be regenerated (that is, the drying tower that has absorbed enough water vapor), and the dry regeneration air sucks out the moisture in the desiccant, and the It is taken out of the dryer to achieve the purpose of dehumidification.

The heatless regenerative adsorption dryer uses “pressure swing adsorption” to achieve the drying effect. Since the ability of the air to hold water vapor is inversely proportional to the pressure, a part of the air after drying (called regeneration gas) decompresses and expands to atmospheric pressure. This pressure change makes the expanded air drier, and then it flows over the desiccant layer that is not connected to the airflow to be regenerated (that is, the drying tower that has absorbed enough water vapor), and the dry regeneration air sucks out the moisture in the desiccant, and the It is taken out of the dryer to achieve the purpose of dehumidification.

| Model | Capacity Nm/min | Voltage | Power (KW) | Air inlet and outlet diameter | Dimensions(mm) |

|---|---|---|---|---|---|

| SLT-W010 | 1.5 | 220V | 0.2 | G1" | 750*435*1470 |

| SLT-W020 | 2.6 | 220V | 0.2 | G1" | 750*460*1470 |

| SLT-W030 | 3.8 | 220V | 0.2 | G1" | 770*460*1670 |

| SLT-W065 | 7.2 | 220V | 0.2 | G1"1/2" | 890*550*1906 |

| SLT-W100 | 11 | 220V | 0.2 | G2" | 1170*680*2028 |

| SLT-W135 | 14 | 220V | 0.2 | G2" | 1170*680*2028 |

| SLT-W185 | 18 | 220V | 0.2 | DN65 | 1340*800*2270 |

| SLT-W235 | 22 | 220V | 0.2 | DN65 | 1340*800*2270 |

| SLT-W265 | 28 | 220V | 0.2 | DN80 | 1450*900*2480 |

| SLT-W320 | 32 | 220V | 0.2 | DN80 | 1450*900*2480 |

| SLT-W365 | 38 | 220V | 0.2 | DN100 | 1700*960*2620 |

| SLT-W450 | 45 | 220V | 0.2 | DN100 | 1700*960*2620 |

| SLT-W550 | 52 | 220V | 0.2 | DN125 | 1980*1200*2814 |

| SLT-W600 | 60 | 220V | 0.2 | DN125 | 1980*1200*2814 |